Functional woven upper fabric

A functional and woven technology, applied in the field of woven fabrics, can solve the problems of time-consuming yield rate, inability to accurately control, etc., to achieve the effect of good wear resistance and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1. Wear-resistant functional woven shoe upper fabric

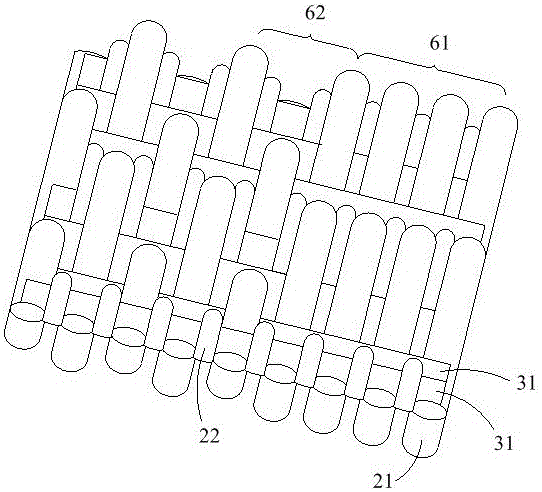

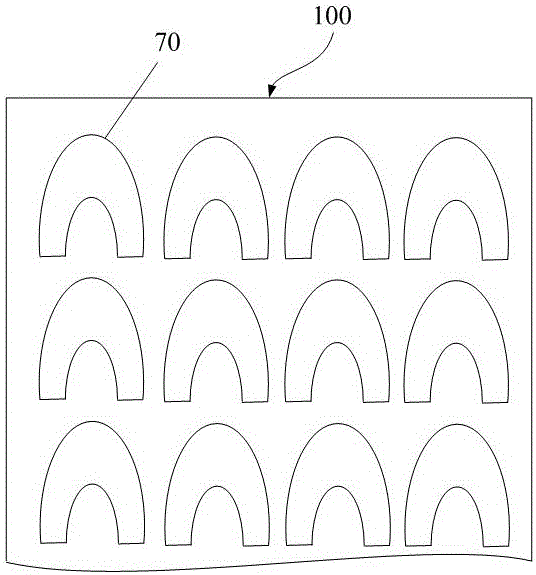

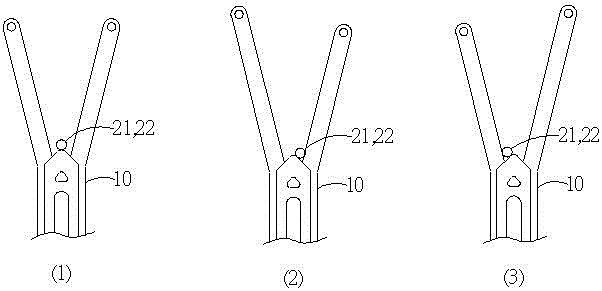

[0041] Please also refer to figure 1 and figure 2A plurality of first warp yarn units 21 and second warp yarn units 22 are parallel and side by side, and the wire diameter of the first warp yarn units 21 is larger than that of the second warp yarn units 22. According to the weaving plan of the tissue pattern 70, the weft yarn units 31 are passed through multiple warp yarn units. Between the first warp unit 21 and the plurality of second warp units 22 , the functional woven shoe upper fabric 100 is produced through a staggered weaving method.

[0042] In the present invention, the first warp yarn units 21 with thicker wire diameters can be closely arranged to form a wear-resistant protrusion 61, or the second warp yarn units 22 with thinner wire diameters can be arranged according to the weaving plan of the weave pattern 70 to form a wear-resistant protrusion 61. The looser arrangement is to form the re...

Embodiment 2

[0044] Embodiment 2: Elastic and wear-resistant functional woven shoe upper fabric

[0045] When the type of yarn is changed to elastic fiber yarn, and the above-mentioned technical solution is combined, in addition to having the above-mentioned wear-resistant function, the elastic yarn can be used to provide appropriate stretching elasticity, and can be configured through the planning of the tissue composition 70 And adjust the gap density between the warp units to avoid large deformation of the cloth surface pattern. In addition, the use of elastic fiber yarn can provide better coverage through its stretching elasticity, and can maintain the integrity of the upper pattern .

[0046] In practice, when the yarn type is elastic fiber yarn, the wire diameter of the first warp yarn unit 21 is between 300 deniers and 1200 deniers, the wire diameter of the second warp yarn unit 22 is 100 deniers to 450 deniers, and the weft yarn The wire diameter of the unit 31 is between 100 deni...

Embodiment 3

[0047] Example 3: Perspective and wear-resistant functional woven shoe upper fabric

[0048] When the type of yarn is monofilament fiber yarn, the strength of monofilament fiber yarn can improve the shortcoming of insufficient strength of traditional composite spinning, because the stiffness of monofilament fiber yarn can increase the pore planning ratio of tissue pattern 70 In practice, the proportion of pore size can reach 20% to 70%. When the pore size ratio is too small, the yarns will cover each other and make the perspective poor. When the pore size ratio is too large, the strength of the overall upper fabric will not match. The most commonly used ratio is 30% to 60%. In addition, the color rendering of monofilament fiber is fuller than that of composite spinning, which can not only highlight the perspective of the upper fabric but also increase the hazy beauty.

[0049] In practice, when the yarn type is monofilament fiber yarn, the wire diameter of the first warp yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com