Treatment method of medium-high-voltage anode foils

A processing method and technology of anode foil, applied in electrolytic coatings, surface reaction electrolytic coatings, electrolytic capacitors, etc., can solve the problems of uneven pores, excessive dissolution, reduction of foil specific volume, etc., to reduce the growth rate and improve the specific volume. , into the effect of increasing the specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

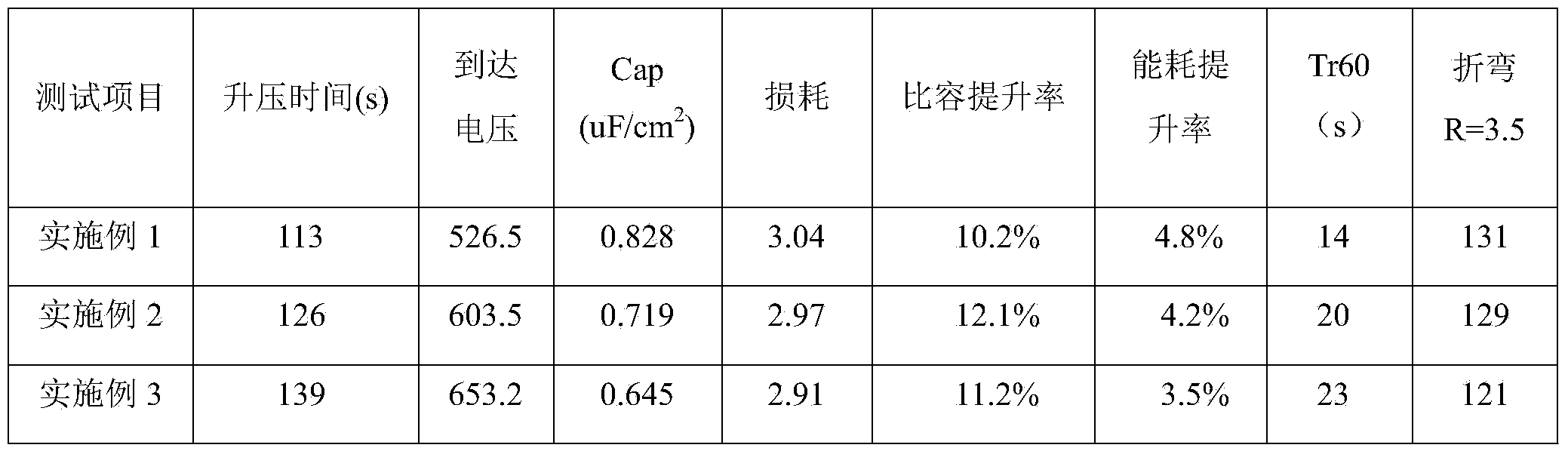

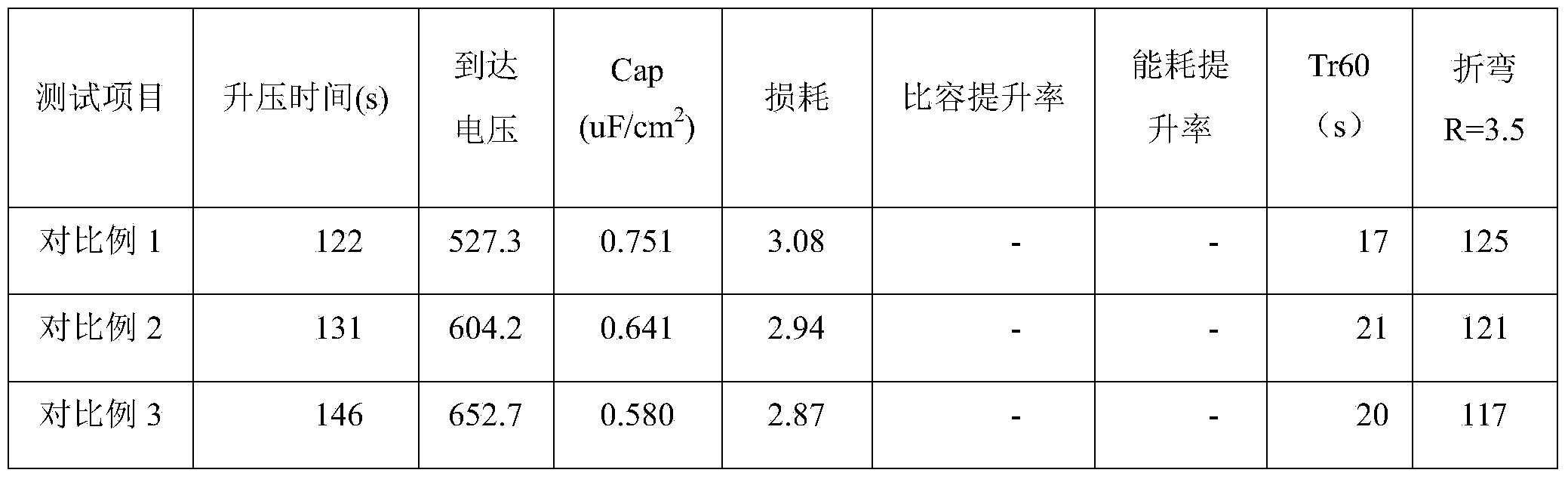

Embodiment 1

[0028] Corrosion foil with a purity of 99.99% is boiled in pure water above 97°C for 2-4 minutes, then boiled in 0.5wt% silicate solution above 97°C for 20-30 minutes, washed with pure water, Put it into 0.2wt% aqueous solution of phosphate and citrate at 85°C for the first-stage chemical formation with a current density of 40Ma·cm -2 After reaching the predetermined voltage of 160V, the constant voltage was kept for 10 minutes; in the mixed solution of 5wt% boric acid and citrate, secondary chemical formation was carried out, and after the predetermined voltage was 320V, the constant voltage was kept for 10 minutes; in the mixed solution of 5wt% boric acid and citrate Carry out three-stage formation in the solution, and keep the constant voltage for 15 minutes after reaching the predetermined voltage of 480V; then carry out four-stage formation in the mixed solution of 5wt% boric acid and citrate, and keep the constant voltage for 20 minutes after reaching the predetermined vo...

Embodiment 2

[0031] Corrosion foil with a purity of 99.99% is boiled in pure water above 97°C for 4-6 minutes, then boiled in 0.5wt% silicate solution above 97°C for 15-20 minutes, washed with pure water, Put it into 0.2wt% aqueous solution of phosphate and citrate at 85°C for the first-stage chemical formation with a current density of 40mA·cm -2 After reaching the predetermined voltage of 180V, the constant voltage is kept for 10 minutes; in the mixed solution of 5wt% boric acid and citrate, the secondary formation is carried out, and after the predetermined voltage is 360V, the constant voltage is kept for 10 minutes; in the mixed solution of 5wt% boric acid and citrate Carry out three-stage formation in the solution, and keep the constant voltage for 15 minutes after reaching the predetermined voltage of 540V; then carry out four-stage formation in the mixed solution of 5wt% boric acid and citrate, and keep the constant voltage for 20 minutes after reaching the predetermined voltage of ...

Embodiment 3

[0034] For corroded foil with a purity of 99.99%, boil it in pure water above 97°C for 6-8 minutes, put it into a 0.5wt% silicate solution above 97°C and boil it for 5-10 minutes, wash it with pure water, put it in 0.2wt%, 85 ℃ phosphate and citrate aqueous solution for the first stage of chemical formation, the current density is 40mA cm -2 After reaching the predetermined voltage of 200V, keep the constant voltage for 10 minutes; perform secondary formation in the mixed solution of 5wt% boric acid and citrate, and keep the constant voltage for 10min after reaching the predetermined voltage of 400V; Carry out three-stage formation in the solution, and keep the constant voltage for 15 minutes after reaching the predetermined voltage of 600V; then carry out four-stage formation in the mixed solution of 5wt% boric acid and citrate, and keep the constant voltage for 20 minutes after reaching the predetermined voltage of 650V; at 550°C After heat treatment for 2 minutes, put it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com