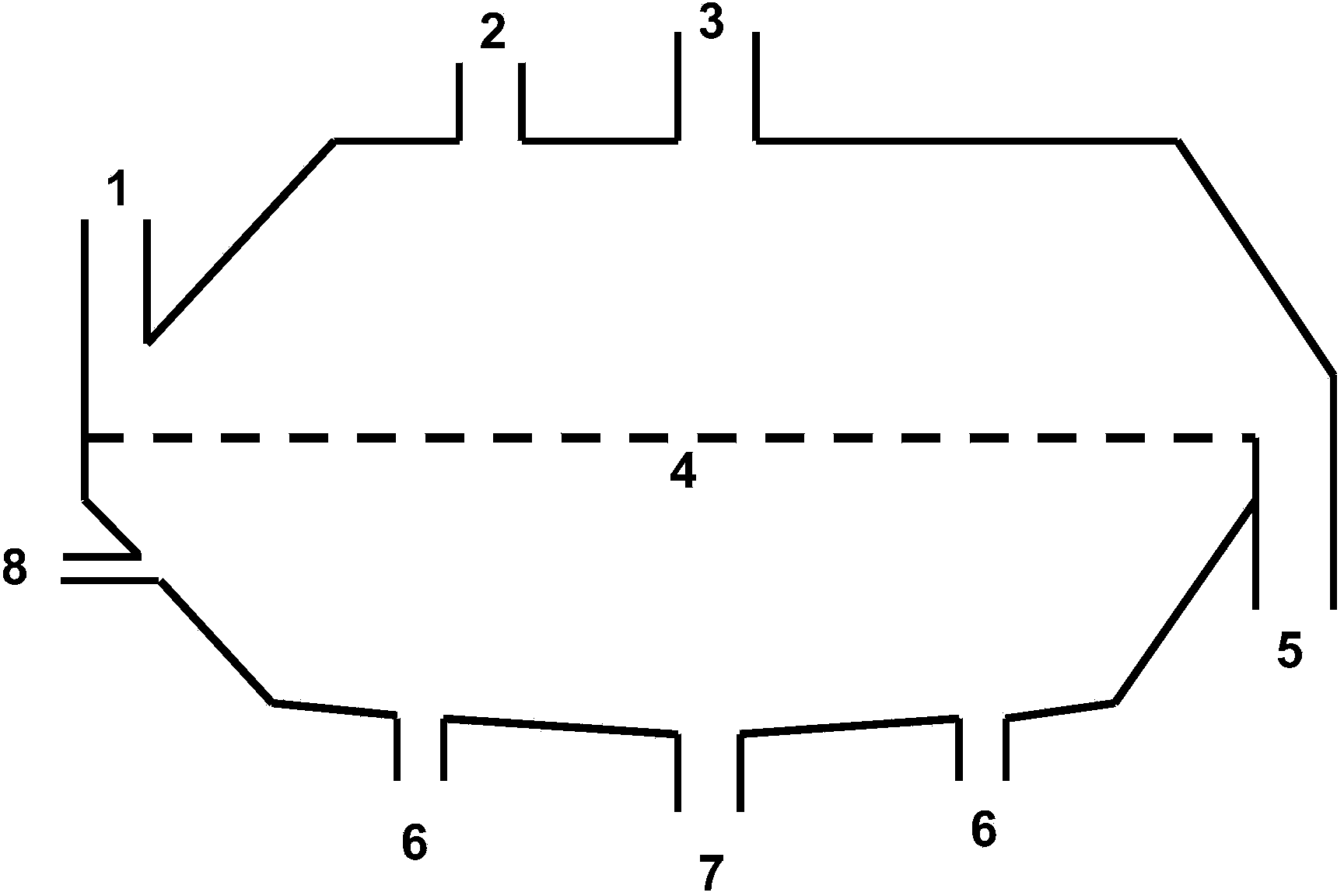

Integrated treatment device and method for cleaning, reducing and drying electrolytic copper powder

A technology of electrolytic copper powder and processing equipment, which is applied in the field of electrolysis, can solve the problems of increased energy consumption, increased labor, leakage, leakage, etc., and achieves the effects of improving anti-oxidation performance, reducing labor, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ordinary electrolytic copper powder is divided into two batches, one batch is processed by conventional process, washed seven times in powder washing machine, washed three times after saponification, dried by centrifugal dryer for 30 minutes, dried and reduced in reduction furnace at 480°C for 2 hours, and then After being crushed by a crusher and classified by an airflow classifier, the bulk density of the sieved -200 mesh copper powder is 1.78g / cm 3 , the oxygen content is 565ppm, and the water content is 0.04%. The other batch is washed 5 times in the electrolytic copper powder cleaning, reduction and drying integrated treatment device, soaked in hydrazine hydrate aqueous solution with a mass fraction of 3% for 30 minutes to reduce and deoxygenate the copper powder, and then use the mass fraction The surface anti-oxidation treatment was carried out with 0.3% BTA aqueous solution, and the immersion time was 40min. After draining the liquid, dehydrate it once by suctio...

Embodiment 2

[0029] Low bulk density electrolytic copper powder is divided into two batches, one batch is processed by conventional process, washed 10 times in powder washing machine, washed three times after saponification, dried by centrifugal dryer for 40min, dried and reduced in reduction furnace at 430℃ for 2.5 hours, and then crushed by a crusher and classified by an airflow classifier, the bulk density of the sieved -200 mesh copper powder is 1.18g / cm 3 , the oxygen content is 765ppm, and the water content is 0.07%. The other batch is washed 5 times in the electrolytic copper powder cleaning, reduction and drying integrated treatment device, soaked in hydrazine hydrate aqueous solution with a mass fraction of 3% for 40 minutes to reduce and deoxygenate the copper powder, and then use mass fraction The surface anti-oxidation treatment was carried out with 0.3% BTA aqueous solution, and the immersion time was 60min. After draining the liquid, dehydrate it once by suction filtration, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com