Planet-like coating jig capable of rotating and revoluting and use method of planet-like coating jig

A self-revolution, planet-like technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem that the coating product cannot completely deposit the film, affect the coating effect, and affect the uniformity of the film. , to increase the amount of coated products, improve production capacity and work efficiency, and achieve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

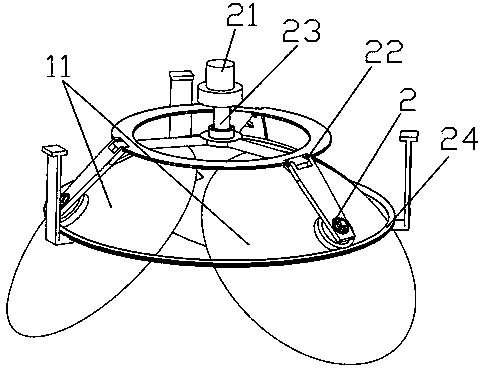

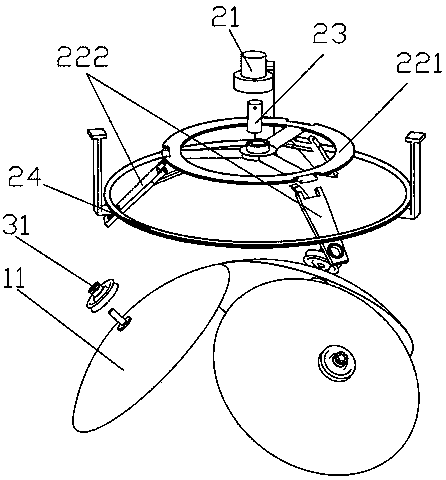

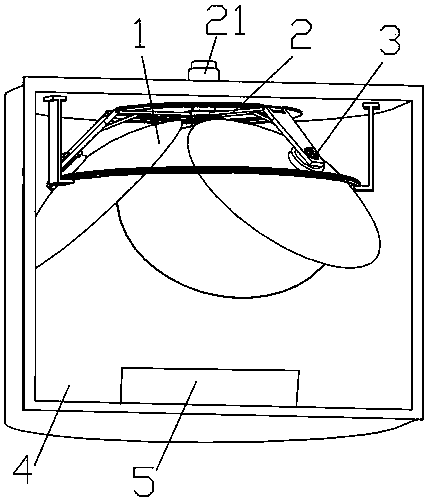

[0025]A planetary-like coating fixture capable of rotation and revolution, the coating fixture is installed above the interior of the coating machine cavity 4, the coating fixture mainly includes a fixture body 1, a revolution system 2 and a rotation system 3, the The jig body 1 described above includes three jig plates 11, the jig plates 11 are umbrella-shaped, and the tip of the middle part of the umbrella-shaped jig plate is provided with a connecting column 12; the revolution system 2 mainly includes a connecting seat 21, a revolution Support 22, revolution center shaft 23 and revolution guide rail 24, connecting seat 21 are installed on the outer top surface of coating machine chamber 4, and revolution center shaft 23 passes through the through hole that coats machine chamber 4 tops and connects with connection seat 21, revolution support respectively 22 is axially installed, and the revolution bracket 22 is installed on the top surface of the coating machine chamber 4; a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com