White wine reduced pressure distillation system and distillation method

A distillation system and liquor technology, which is applied in the vacuum distillation system and distillation field of liquor, can solve the problems of miscellaneous taste, few applications in the food industry, and can not meet the taste requirements, and achieve the effect of lowering the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

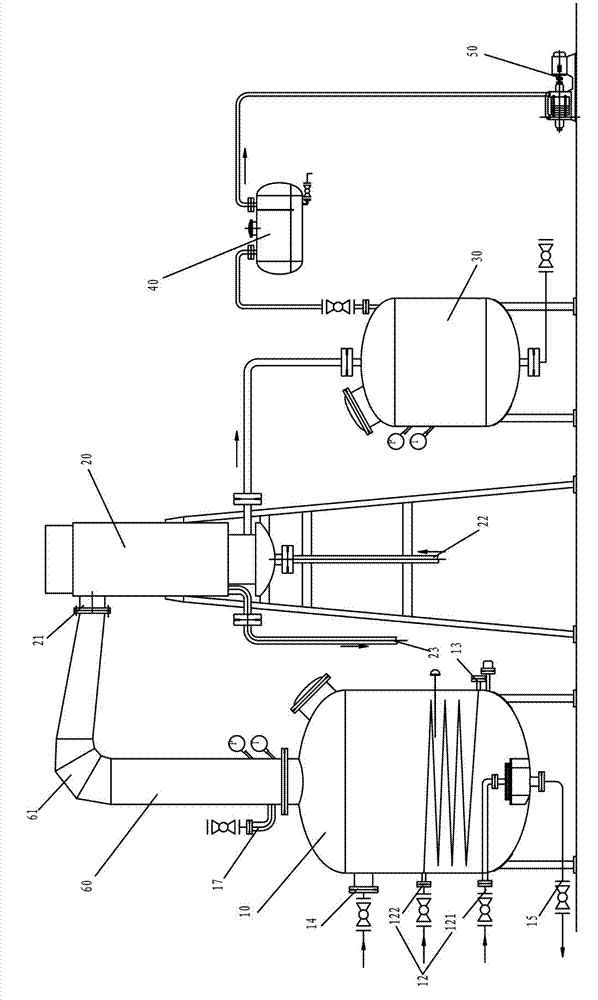

[0030] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. As a part of this specification, the principles of the present invention are explained through embodiments, and other aspects, features and advantages of the present invention will become clear through this detailed description. In the referenced drawings, the same or similar components in different drawings are represented by the same reference numerals, and the drawings do not limit the overall design of the liquor vacuum distillation system of the present invention.

[0031] Such as figure 1 As shown, the embodiment 1 of the present invention provides a reduced-pressure distillation system for liquor, which includes a distillation retort 10 and a condenser 20 that is in sealed communication with the distillation retort. The bottom of the condenser is connected to a liquor storage tank 30 through a pipe. The distillation system also includes a vacuum buffer tank 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com