Production method of magnesium sulfate monohydrate

A production method, the technology of magnesium sulfate, applied in the direction of magnesium sulfate, etc., can solve the problems of high energy consumption, complex process of magnesium sulfate monohydrate, high equipment requirements, etc., and achieve the effects of low energy consumption, good commercial effect and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

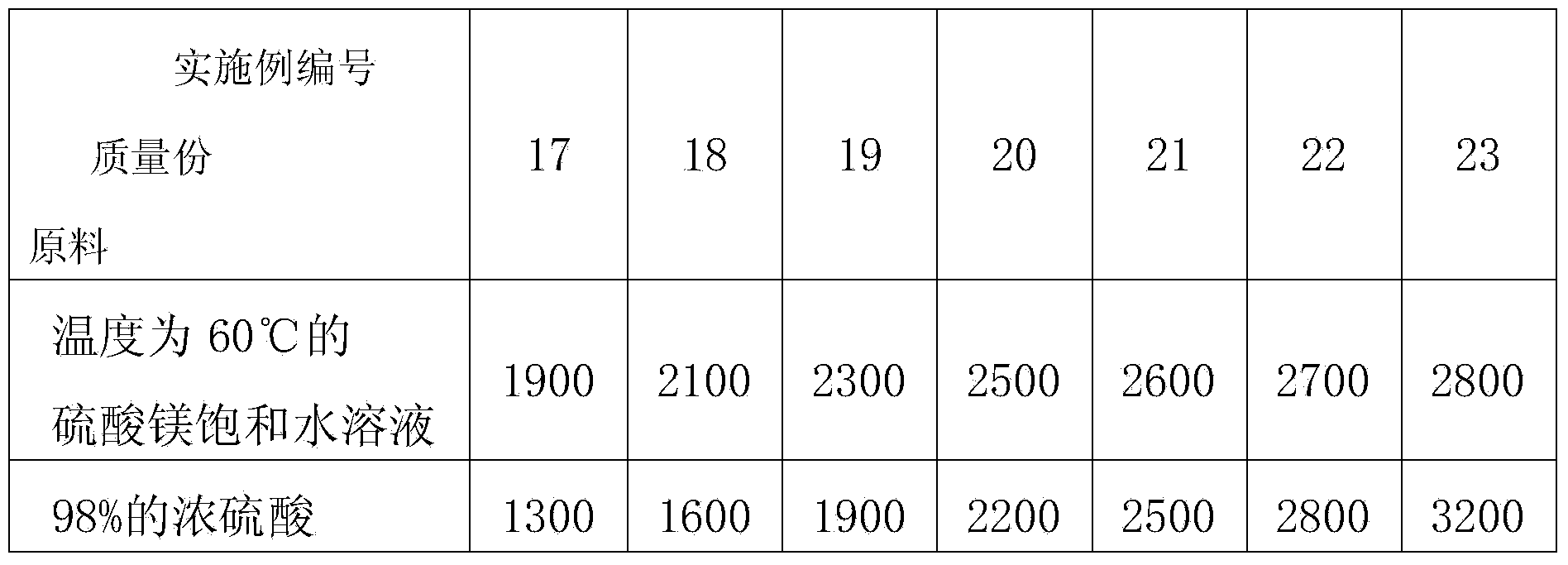

Examples

Embodiment 1

[0026] Pump 2000Kg of saturated magnesium sulfate solution at 60°C into the glass-lined reactor, start stirring, slowly add 760Kg of sulfuric acid with a mass concentration of 90% or 650Kg of sulfuric acid with a mass concentration of 98%, and continue stirring for 1 hour after the addition is complete. Then pump it into the plate and frame filter press for filtration while it is hot. After the filtration, pump a saturated solution of magnesium sulfate at 70°C into the plate and frame filter press to wash the filter cake once, then wash it with tap water for 1-2 times, combine the filtrate and washing liquid, and return to the filter cake. For the production of magnesium sulfate heptahydrate or magnesium sulfate solution. Take out the filter cake and send it to a vibrating bed drier to dry at 120-150°C for 0.5 hour to obtain magnesium sulfate monohydrate.

Embodiment 2

[0028] Add 2000Kg of magnesium sulfate heptahydrate into the glass-lined reactor, slowly add 680Kg of sulfuric acid with a mass concentration of 90% or 600Kg of sulfuric acid with a mass concentration of 98%, and slowly start the stirring reaction for 80 minutes after the addition is completed. Then pump it into the plate and frame filter press to filter while it is hot. After the filtration, pump the saturated solution of magnesium sulfate at 70°C into the plate and frame filter press to wash the filter cake once, then wash it with tap water for 1-2 times, and combine the filtrate and washing solution. Return for the production of magnesium sulfate heptahydrate or magnesium sulfate solution. Take out the filter cake and send it to a vibrating bed drier to dry at 120-150°C for 0.5 hour to obtain magnesium sulfate monohydrate.

Embodiment 3

[0030] Pump 2000Kg of saturated magnesium sulfate solution at 80°C into the glass-lined reactor, start stirring, slowly add 720Kg of sulfuric acid with a mass concentration of 90% or 620Kg of sulfuric acid with a mass concentration of 98%, and continue stirring for 80 minutes after the addition is complete. Then pump it into the plate and frame filter press for filtration while it is hot. After the filtration, pump a saturated solution of magnesium sulfate at 70°C into the plate and frame filter press to wash the filter cake once, then wash it with tap water for 1-2 times, combine the filtrate and washing liquid, and return to the filter cake. For the production of magnesium sulfate heptahydrate or magnesium sulfate solution. Take out the filter cake and send it to a vibrating bed drier to dry at 120-150°C for 0.5 hour to obtain magnesium sulfate monohydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com