Wood veneer cutter

A cutting machine and veneer technology, applied in the field of wood processing, can solve the problems of waste of wood resources, increase production cost, size requirements and poor control, and achieve the effects of accurate counting, avoiding errors, and flexible and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

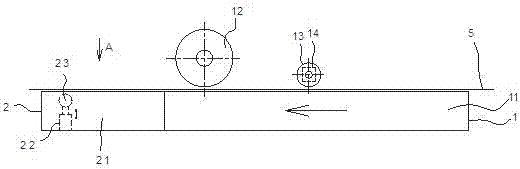

[0015] The present invention as Figure 1-2 As shown, it includes a transmission section 1 and a cutting section 2 in sequence, and the transmission section 1 includes a transmission table 11, a motor, a driving roller 12, a driven roller 13 and a counter 14, the motor drives the driving roller 12, and the Driving roller 12 and driven roller 13 are respectively arranged on the top of described transmission table 11, and described driving roller 12 is positioned at the front of described driven roller 13, and described counter 14 is connected on described driven roller (that is, is connected on on the rotating shaft of the driven roller); the driven roller is connected by a bracket and arranged above the transmission table;

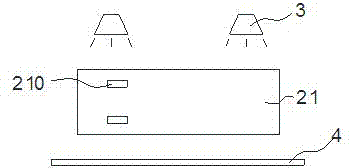

[0016] Described cutting segment 2 comprises workbench 21, lift mechanism 22 and cutter 23, and described workbench 21 is hollow structure, and described lift mechanism 22 and cutter 23 are arranged in described workbench 21, and described workbench The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com