Tube expanding device of tube expander

The technology of a tube expander and a tube expander is applied in the field of processing or metal tube testing and tube expander device, which can solve the problems of unfavorable assembly, complex structure and operation, uneven diameter expansion, etc., to ensure stability and easy operation. , the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

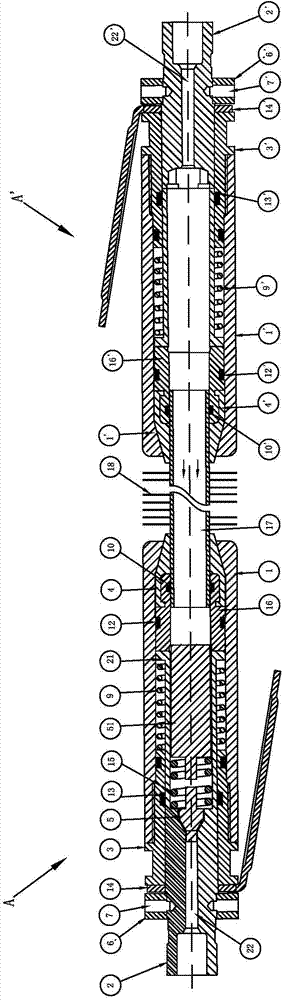

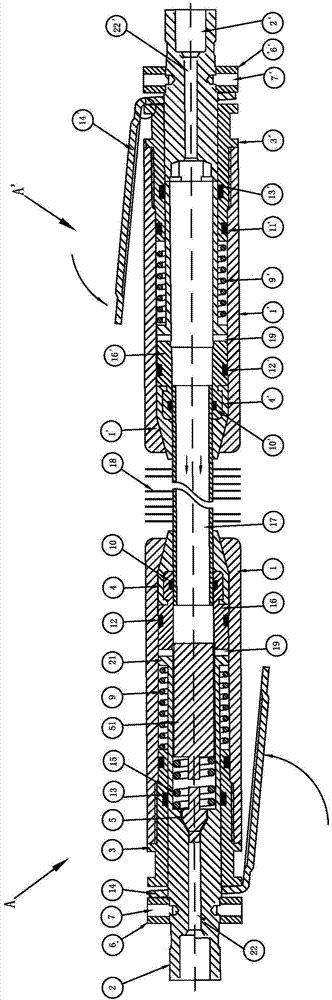

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] In order to clarify the description, the position and direction of the relevant parts are first limited as follows: figure 1 For reference, "inward" refers to the direction toward the center, "outer" refers to the direction toward the left and right ends; "inner" refers to the direction toward the axis, and "outer" refers to the direction toward the top and bottom.

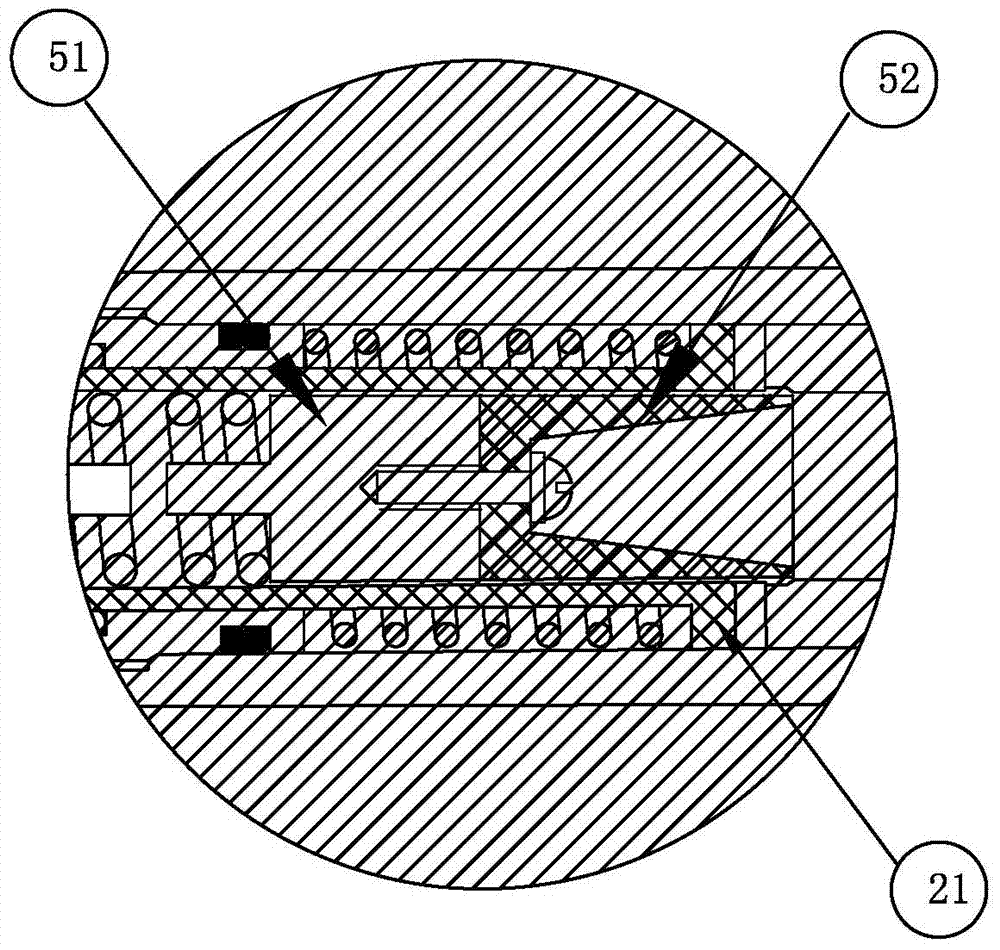

[0020] A tube expander device of a tube expander according to the present invention is composed of a liquid inlet part A' and a fixing seat A, both of which have the same clamping mechanism: the inner ends of the cylindrical shells 1, 1' are equipped with Conical collet 4, 4', the inner end of the cylindrical shell is made into a concave conical surface corresponding to the conical collet, so that the two can slide and fit on the conical surface. When the conical collet retracts, its clamping diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com