Lactose-free acidified milk and preparation method thereof

A technology of fermented milk and lactose, applied in the field of lactose-free fermented milk and its preparation, can solve the problems that lactase cannot produce lactose-free fermented milk, the content of lactose does not reach the lactose-free limit, and the enzymatic hydrolysis efficiency is reduced, so as to achieve easy absorption , Nutrient-rich and comprehensive, full effect of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

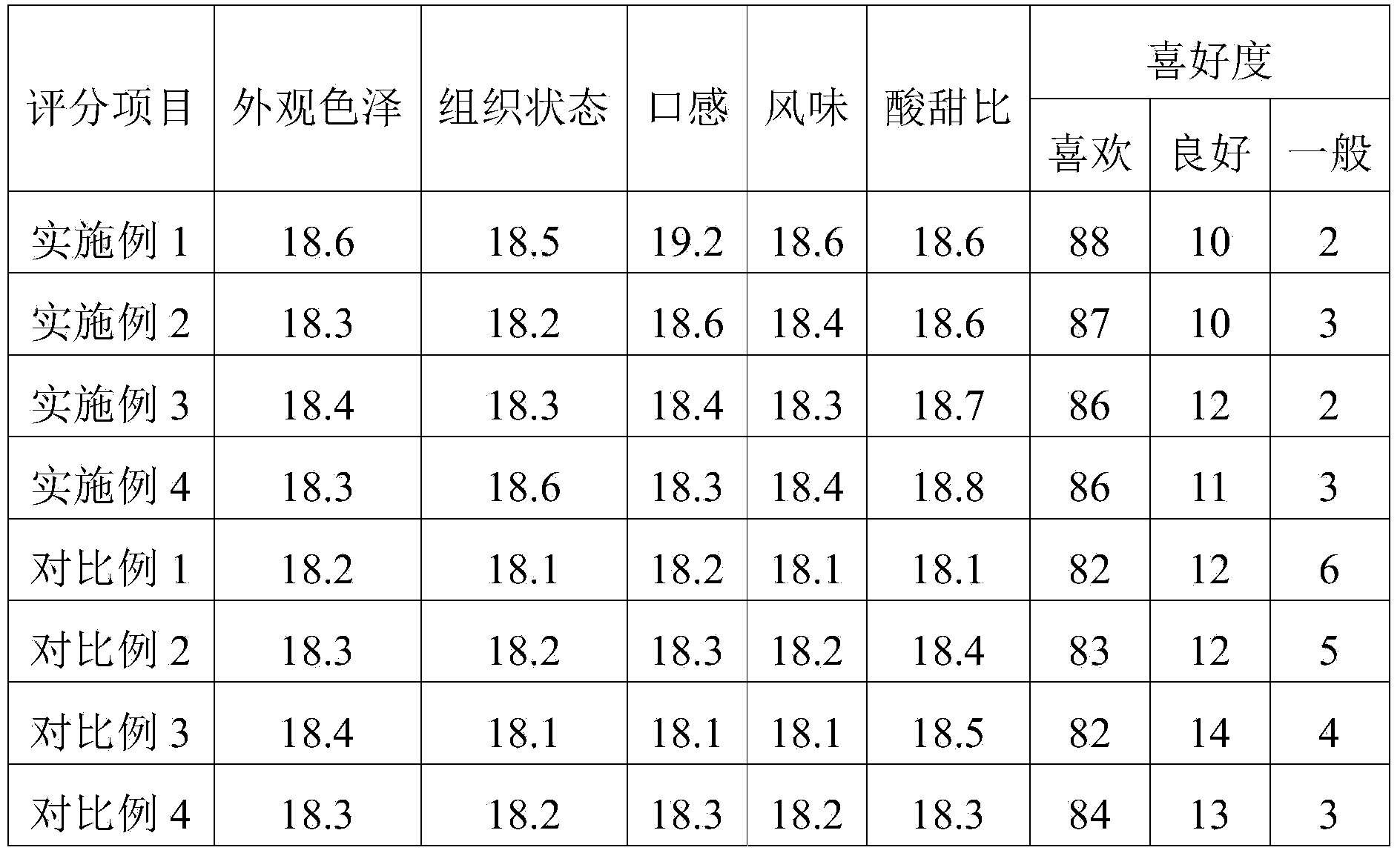

Embodiment 1

[0043] (1) According to the ratio of 89.97% of whole milk, 7% of white sugar, 0.03% of lactase produced by Kluyveromyces fragilis, 0.1% of agar, 0.2% of pectin, 2% of inulin, and 0.7% of natural starch , mixed and stirred at 45°C for 15 minutes to obtain mixed solution A;

[0044] (2) Homogenize the mixed solution A, the primary homogenization pressure is 15Mpa, the homogenization temperature is 54°C, and then sterilized at 90°C for 5 minutes and cooled to 37°C to obtain the mixed solution B;

[0045] (3) Add Lactobacillus bulgaricus 1×10 to the mixture B 6 cfu / mL, Streptococcus thermophilus 1×10 6 cfu / mL, Lactobacillus casei subspecies 2×10 6 cfu / mL and 0.1% lactase produced by Aspergillus niger, enzymatic hydrolysis and fermentation are performed simultaneously at 37°C, and the acidity reaches 71°T after 8.5 hours, stop fermentation, cool to 17°C, fill, and refrigerate at 2°C, that is Get lactose-free fermented milk.

[0046] The lactose content was tested at 0 days, 7 d...

Embodiment 2

[0048] (1) According to the ratio of 91.96% of skim milk, 0.04% of lactase produced by Kluyveromyces lactis, 6% of fructose syrup, 0.2% of pectin, 1.5% of galactooligosaccharides, and 0.3% of acetylated distarch phosphate Ingredients, mixed and stirred at 40°C for 20 minutes to obtain mixed solution A;

[0049] (2) Homogenize the mixed solution A, the first-stage homogenization pressure is 15Mpa, the second-stage homogenization pressure is 3Mpa, the homogenization temperature is 58°C, and then sterilized at 92°C for 5 minutes and cooled to 39°C to obtain the mixed solution B;

[0050] (3) Add Lactobacillus bulgaricus 3×10 to the mixture B 6 cfu / mL, Streptococcus thermophilus 3×10 6 cfu / mL, Lactobacillus plantarum ST-III 4×10 6 cfu / mL and 0.06% lactase produced by Aspergillus oryzae, enzymatic hydrolysis and fermentation are carried out simultaneously at 39°C. After 7 hours, the acidity reaches 73°T, the fermentation is stopped, cooled to 20°C, and filled. The mass ratio of ...

Embodiment 3

[0053] (1) According to skim 50% milk 89.44%, Kluyveromyces fragilis producing lactase 0.06%, white sugar 7%, agar 0.1%, fructooligosaccharide 1%, inulin 1%, hydroxypropyl distarch phosphate 0.2% of ester, 0.2% of gelatin, and 1% of whey protein powder are mixed and stirred at 42°C for 20 minutes to obtain a mixed solution A;

[0054] (2) Homogenize the mixed solution A, the first-stage homogenization pressure is 18Mpa, the second-stage homogenization pressure is 2Mpa, the homogenization temperature is 60°C, and then sterilized at 95°C for 5 minutes and cooled to 42°C to obtain the mixed solution B;

[0055] (3) Add Lactobacillus bulgaricus 6×10 to the mixture B 6 cfu / mL, Streptococcus thermophilus 6×10 6 cfu / mL, Lactobacillus rhamnosus 6×10 6 cfu / mL, Lactobacillus acidophilus 6×10 6 cfu / mL, Lactococcus lactis 6×10 6 cfu / mL and 0.04% lactase produced by Aspergillus oryzae, stir evenly and then fill, enzymolysis and fermentation are carried out simultaneously at 42°C, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com