A kind of lithium-ion battery silicon-based nanocomposite negative electrode material and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in the field of electrochemical power sources, can solve the problems of reducing the overall specific capacity of negative electrode materials, low specific capacity, and high cost, and achieve the goal of reducing the first irreversible capacity loss, huge application potential, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

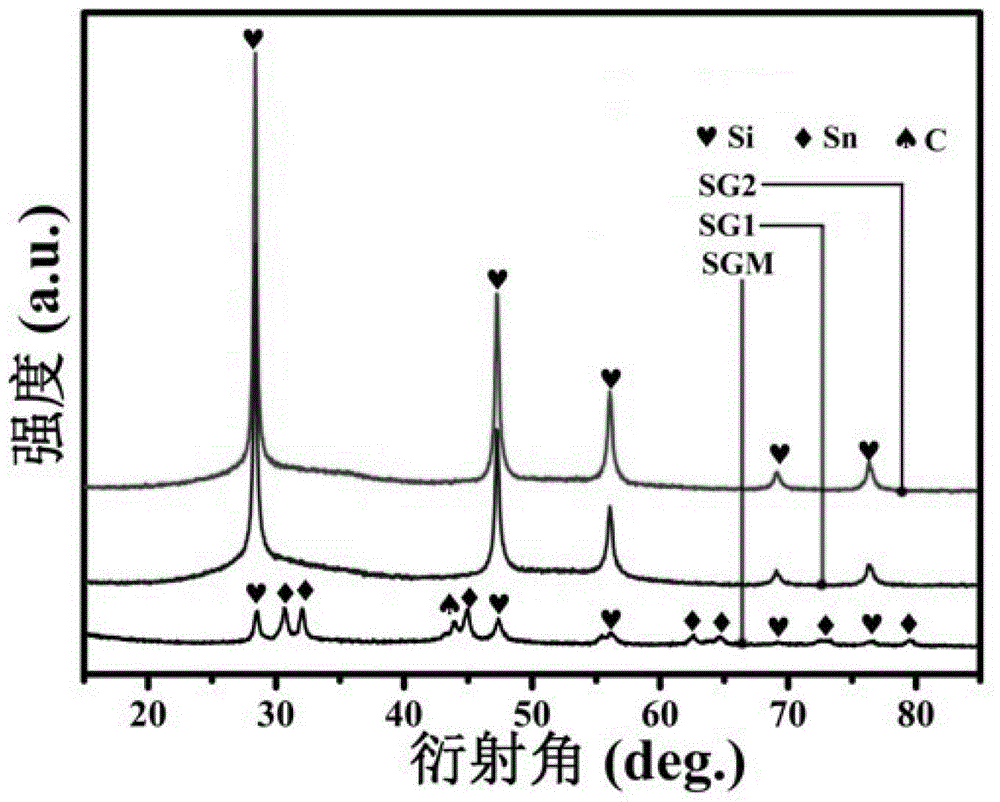

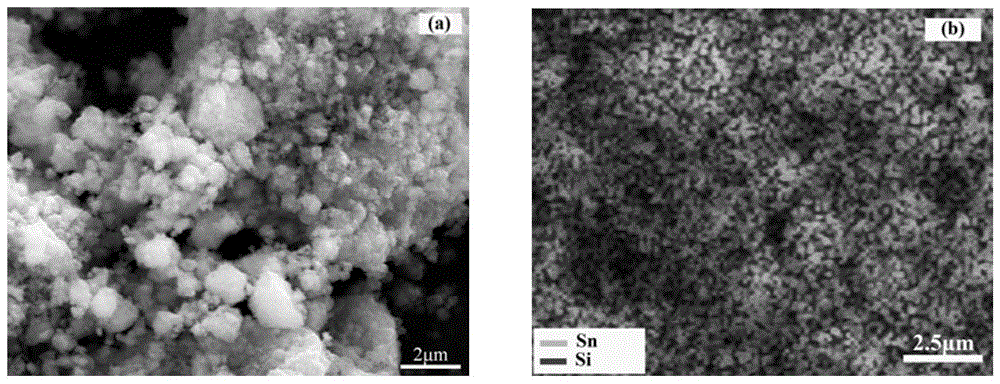

[0029] Si obtained by high energy ball milling 70 sn 10 C 20 (SGM) nano-bicontinuous phase composite material, and used as a lithium-ion battery anode material for electrochemical performance testing.

[0030] 1. For the nominal composition Si 70 sn 10 C 20 In terms of the atomic percentage, the atomic percentage of the silicon element is 70%, and the atomic percentage of the tin element is 10%, meeting the composition range required in the technical proposal.

[0031] 2. Mix the selected raw materials silicon powder, tin powder and graphite powder according to the proportion (silicon: 70at.%, tin: 10at.%) and put them into the ball milling tank matching the ball milling equipment. In this embodiment, the high-energy ball mill selects bearing steel balls with diameters of 10 mm, 8 mm and 5 mm, and the mass ratio of balls to mixed powder is 16:1. The ball milling was carried out under an argon protective atmosphere, and the ball milling speed was 250 rpm. After 20 hours...

Embodiment 2

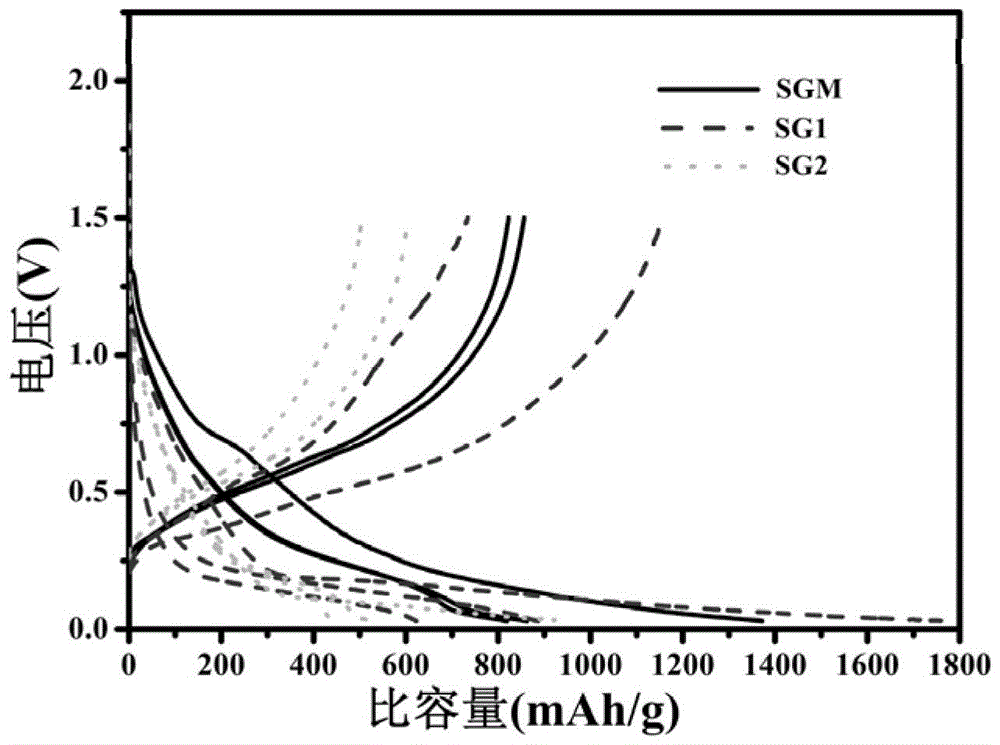

[0038] The SGM nano-bicontinuous phase composite material prepared in Example 1 was used as an active material to prepare a battery pole piece, and the battery was assembled with metal lithium as a counter electrode. The battery preparation method and battery assembly conditions are the same as in Example 1. The test conditions are: charge and discharge voltage range 0.03-1.5V, first charge and discharge at a rate of 0.5C for 30 cycles, and then charge and discharge at a rate of 1C for 10 cycles Cycle, and then return to 0.5C rate charge and discharge for 10 cycles. Figure 4 The rate charge and discharge performance curve of the battery assembled with lithium metal as the counter electrode is prepared for the SGM composite material as the active material. It can be seen that the specific capacity of the electrode is maintained at 880mAh / g in the first 30 cycles of charging and discharging at a rate of 0.5C, and when the charge-discharge current density is doubled to 1C, its s...

Embodiment 3

[0040] The SGM nano-bicontinuous phase composite material prepared in Example 1 was used as an active material to prepare a battery pole piece, and the battery was assembled with metal lithium as a counter electrode. The battery preparation method and battery assembly conditions are the same as in Example 1, and the test conditions are: the charge and discharge voltage range is 0.03-1.5V, and the charge and discharge are carried out at a rate of 0.1C. Figure 5 Shown is the charge-discharge specific capacity and coulombic efficiency diagram of the SGM nano-bicontinuous phase composite anode material cycled 25 times. It can be seen from the figure that its charge and discharge capacity is maintained at around 700mAh / g. At the same time, the coulombic efficiency of charging and discharging is basically close to 100%. In the process of cyclic charging and discharging, the capacity suddenly increases, corresponding to Figure 5 In about the ninth cycle, a mutation occurs, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com