Handheld Fiber Optic Coupler and How to Use It

A fiber optic coupler and hand-held technology, applied in the mechanical field, can solve problems such as project quality degradation, inability to obtain test data, and inaccurate fiber cores, and achieve the effects of speeding up construction, reducing costs, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

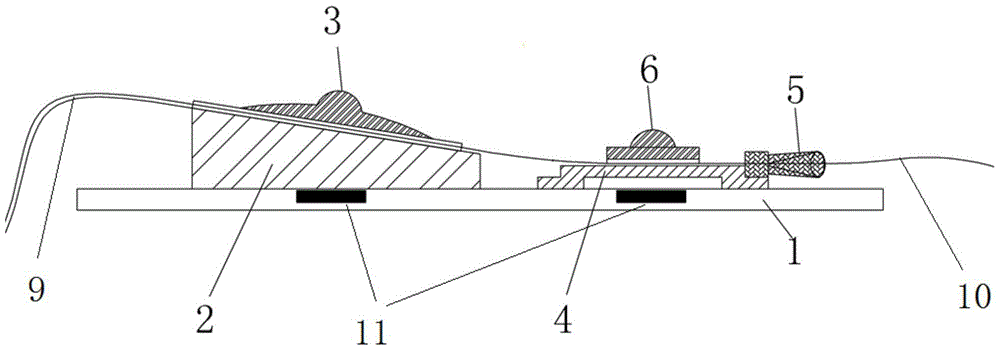

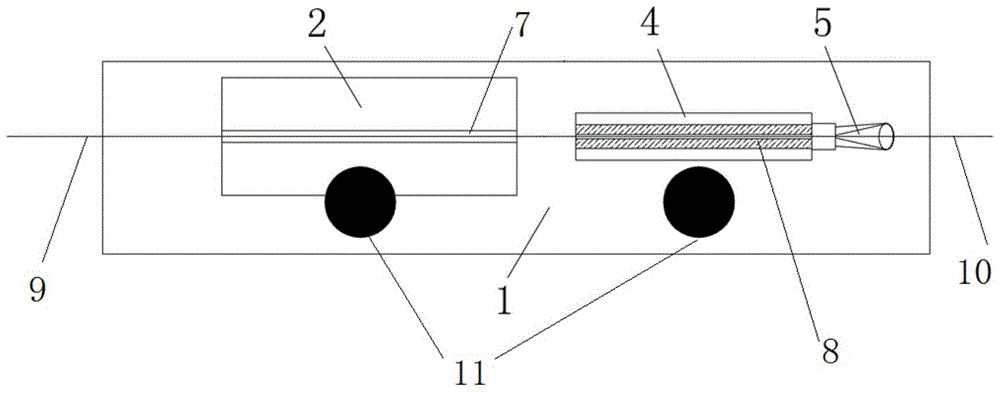

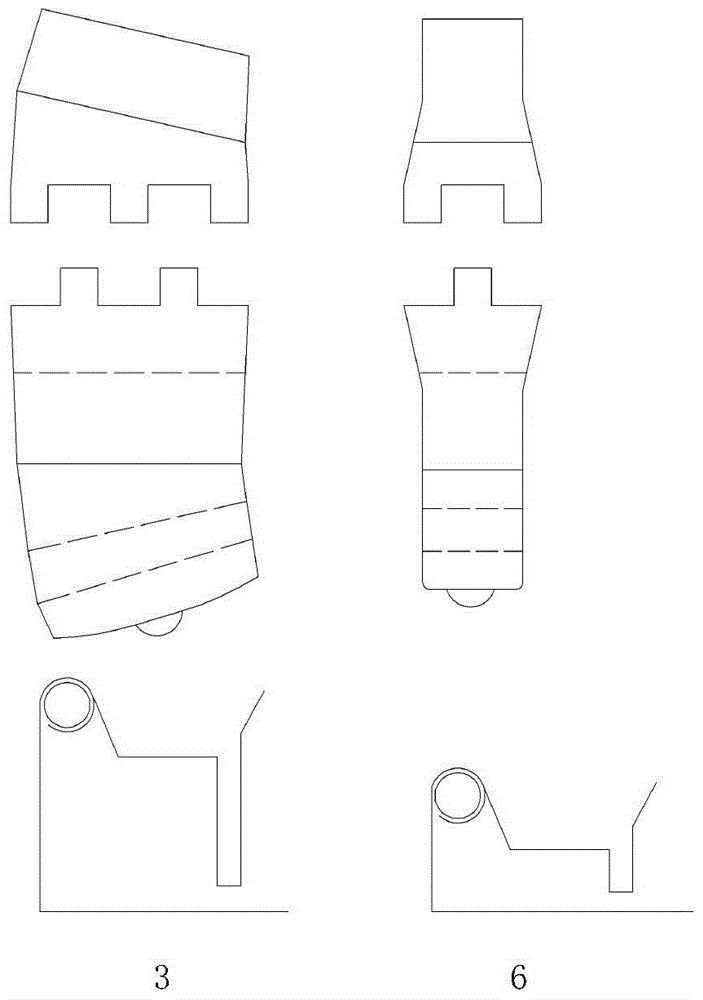

[0041] Such as figure 1 , 2 , 3, the coupler is composed of base 1 made of epoxy resin board, pigtail table 2 made of plastic block, pigtail board 3, coupling body 4, fiber guide hole 5 and fiber board 6, the tail The fiber platform 2 , the fiber pigtail board 3 , the coupling body 4 , the fiber board 6 and the magnet 11 are fixed on the base 1 . Base 1 is 70mm long and 20mm wide.

[0042] The fiber pigtail table 2 has a width of 10 mm and a length of 30 mm. The height of one end close to the coupling body 4 is 3 mm, and the height of the other end is 7 mm. A shallow groove 7 with a depth of 0.5 mm is provided on the central axis of the pigtail stand 2 , and the fiber tail 9 penetrates through the shallow groove 7 .

[0043] The fiber guide hole 5 is connected with the coupling body 4, and the coupling body 4 is provided with a coupling slot 8 for coupling on the central axis. One side of the coupling slot 8 faces the pigtail table 2, and the other side faces the fiber guid...

Embodiment 2

[0046] Such as Figure 5 As shown, the present embodiment is used for single-pan test construction, and its construction method includes the following steps:

[0047] The first step: find out the optical fiber 10 under test;

[0048] Strip the single-reel test optical cable, take out the tested optical fiber 10, which is 1 meter long, remove the coating layer of the optical fiber with a blade, and prepare the end face for future use.

[0049] The second step: connect the pigtail 9 and the test instrument;

[0050]Take out the single-ended pigtail 9 for testing, and connect the flange head side of the single-ended pigtail 9 to the test instrument. Turn on the instrument and adjust it to the real-time state. The other side of the test single-ended pigtail 9 is removed with a blade for 15 cm of optical fiber coating, and the end face is prepared. Put the prepared pigtail 9 into the pigtail table 2 from the left side of the fiber coupler, and the head of the pigtail 9 needs to...

Embodiment 3

[0062] Such as Figure 5 As shown, the present embodiment is used for obstacle checking in optical cable construction, and its specific construction method includes the following steps:

[0063] The first step: find out the optical fiber 10 under test;

[0064] Open the optical cable splice box, find out the optical fiber corresponding to the obstacle optical fiber number, remove the fusion splicing point, take out the tested optical fiber 10 with a length of 1 meter, remove the coating layer of the optical fiber with a blade, and prepare the end face for use. Obstruction points may be on either side of the test point.

[0065] The second step: connect the pigtail 9 and the test instrument;

[0066] Take out the single-ended pigtail 9 for testing, and connect the flange head side of the single-ended pigtail 9 to the test instrument. Turn on the instrument and adjust it to the real-time state. The other side of the test single-ended pigtail 9 is removed with a blade for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com