Engine run-in test bench and floating docking device and its adjustment assembly

A technology of docking device and adjusting components, which is applied in the direction of engine testing, measuring device, machine/structural component testing, etc., can solve the problem of high precision requirements of axial guide structure, and achieve fast docking, reduce processing precision requirements, The effect of reducing the impact force of the butt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

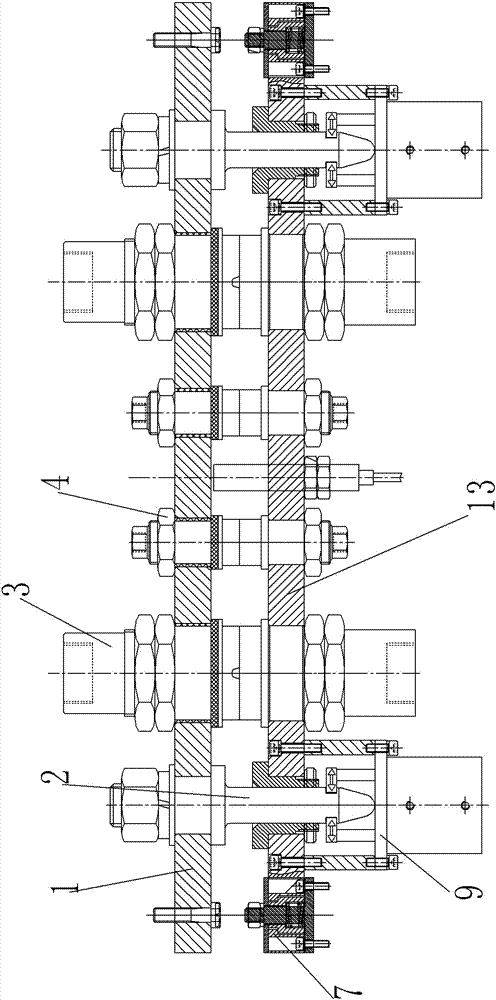

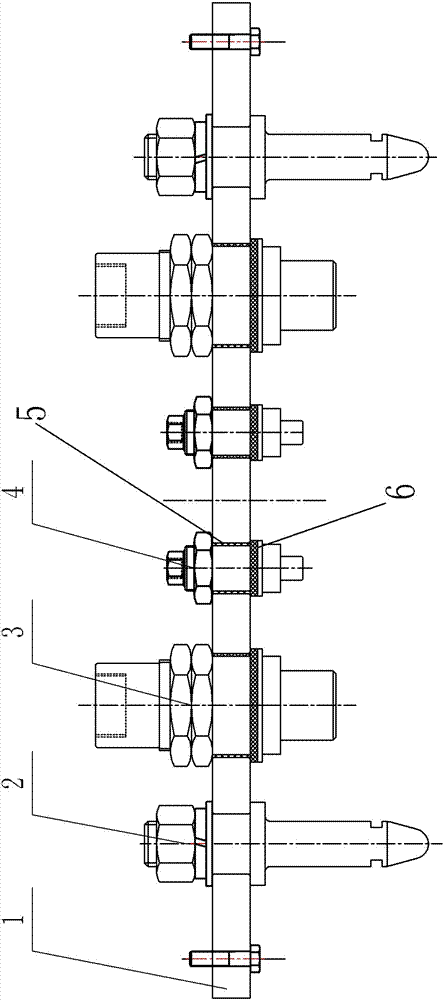

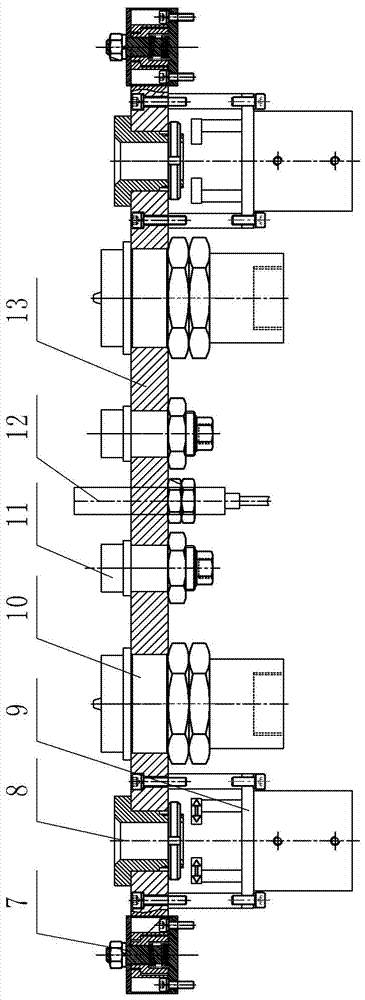

[0030] Such as Figure 1 to Figure 7 As shown, an embodiment of a floating docking device for an engine running-in test bench, the floating docking device in this embodiment includes two docking plates arranged oppositely along the up and down direction, and the two docking plates are respectively an upper docking plate 1 and a lower docking plate 13 , wherein the upper docking plate 1 is assembled on the moving mounting frame fixed on the pallet trolley of the engine running-in test bench and moves with the moving mounting frame, while the lower docking plate 13 is assembled on the running-in stand of the engine running-in test bench On the static mounting frame 32, the upper docking plate 1 is provided with a pipeline male connector 3 and a line male connector 4. When the pipeline male connector 3 and the circuit male connector 4 are installed on the upper docking plate 1, the pipeline male connector 3 and the The elastic gasket 6 and the elastic bushing 5 are set on the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com