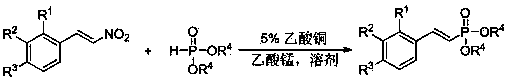

Method for preparing (E)-2-aryl vinyl phosphonate derivatives

A technology of aryl vinyl phosphonate and aryl vinyl, which is applied in the field of preparation of organic compounds, can solve the problems of high cost, narrow application range of substrates, difficult operation, etc., achieve high raw material utilization rate and reduce reaction waste Production and emission, high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

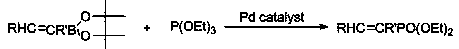

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one: ( E )-Synthesis of methyl 2-styryl phosphonate

[0038] With 1-nitro-2-styrene, dimethyl phosphite as raw materials, the reaction steps are as follows:

[0039] Add 0.073 g (0.5 mmol) of 1-nitro-2-styrene, 0.057 g (0.5 mmol) of dimethyl phosphite, 0.135 g (0.5 mmol) of manganese acetate, and 0.005 g (0.025 mmol) of copper acetate into the reaction flask. ) and 30 milliliters of methanol, reacted at 60 °C; TLC followed the reaction until it was completely over; the crude product obtained after the reaction was separated by column chromatography (petroleum ether: ethyl acetate=4:1), and the target product (yield 63% ). The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.69 – 7.32 (m, 6H), 6.20 (t, J = 17.6 Hz, 1H), 3.76 (d, J = 11.2 Hz, 6H).

Embodiment 2

[0040] Embodiment two: ( E )-Synthesis of ethyl 2-styryl phosphonate

[0041]Using 1-nitro-2-styrene and diethyl phosphite as raw materials, the reaction steps are as follows: add 0.073 g (0.5 mmol) of 1-nitro-2-styrene and diethyl phosphite to the reaction flask 0.069 g (0.5 mmol), 0.20 g (0.75 mmol) of manganese acetate, 0.005 g (0.025 mmol) of copper acetate and 30 ml of methanol were reacted at 60°C; TLC followed the reaction until it was completely completed; Analysis and separation (petroleum ether: ethyl acetate=4:1) to obtain the target product (yield 80%). The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.68 – 7.35 (m, 6H), 6.19 (t, J = 17.6 Hz, 1H), 4.06 (m, 4H), 1.28 (t, J = 7.1 Hz, 6H).

[0042] by( E )-2-ethyl styryl phosphonate as raw material to synthesize 1-amino-2-phenylethyl phosphonic acid, the reaction steps are as follows:

[0043] (1) Add ( E )-ethyl 2-styrylphosphonate (0.24 g, 1 mmol), ammonia water (0.35 g...

Embodiment 3

[0047] Embodiment three: ( E )-Synthesis of isopropyl 2-styryl phosphonate

[0048] With 1-nitro-2-styrene and diisopropyl phosphite as raw materials, the reaction steps are as follows:

[0049] Add 0.073 g (0.5 mmol) of 1-nitro-2-styrene, 0.12 g (0.75 mmol) of diisopropyl phosphite, 0.20 g (0.75 mmol) of manganese acetate, and 0.005 g (0.025 mmol) of copper acetate into the reaction flask. ) and 30 milliliters of methanol, reacted at 60°C; TLC followed the reaction until it was completely over; the crude product obtained after the reaction was separated by column chromatography (petroleum ether:ethyl acetate=4:1), and the target product (yield 82% ). The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.70 – 7.40 (m, 6H), 6.21 (t, J = 17.6 Hz, 1H), 4.75-4.70 (m, 2H), 1.27 (m, 12H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com