A seam starter with mobile function

A mobile function and front-starting technology, which is applied in the field of mechanical automation engineering, can solve the problems that the seam starting equipment cannot meet the on-site rescue requirements, and achieve the effect of compact structure, strong environmental adaptability, and stable seam start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

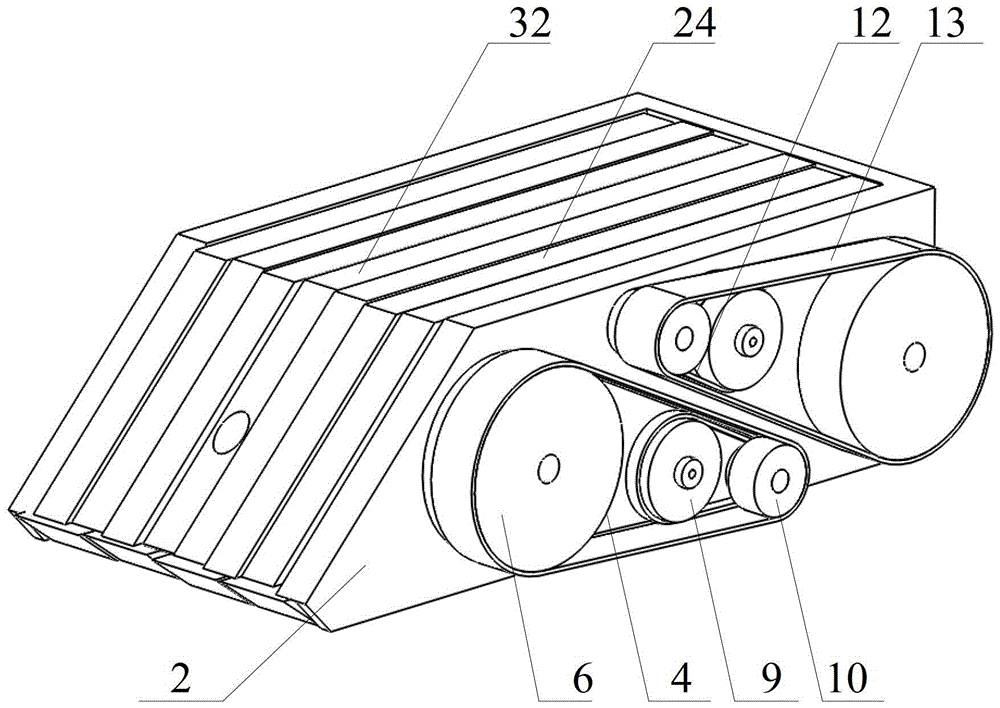

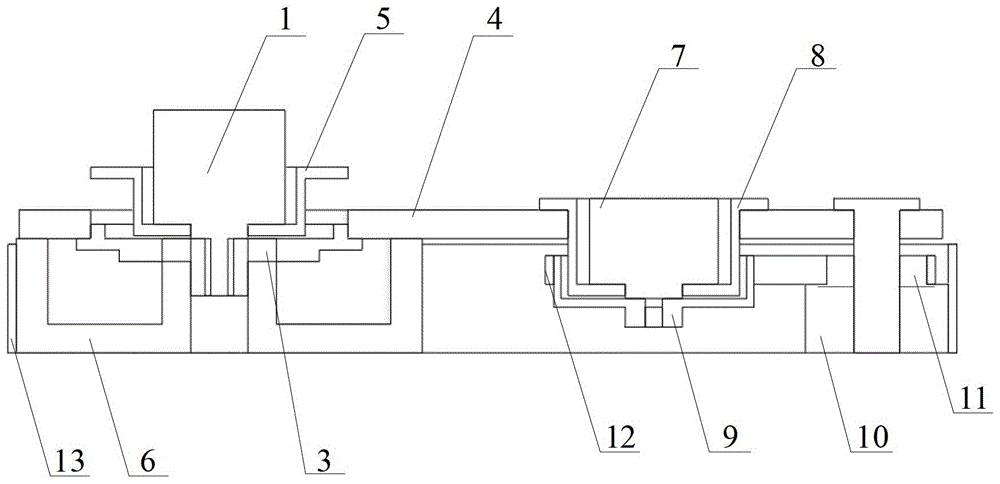

[0030] Such as figure 1 As shown, the present invention includes a seam starting mechanism, a swing arm mechanism, a driving mechanism and a casing 2, wherein a swing arm mechanism is respectively installed on both sides of the casing 2, and in this embodiment, two swing arms are respectively installed on both sides of the casing 2 Each side is divided into front and rear respectively, and the swing arm mechanisms on both sides of the shell 2 are symmetrically arranged; each swing arm mechanism is equipped with a driving mechanism that drives the movement of the seam starter.

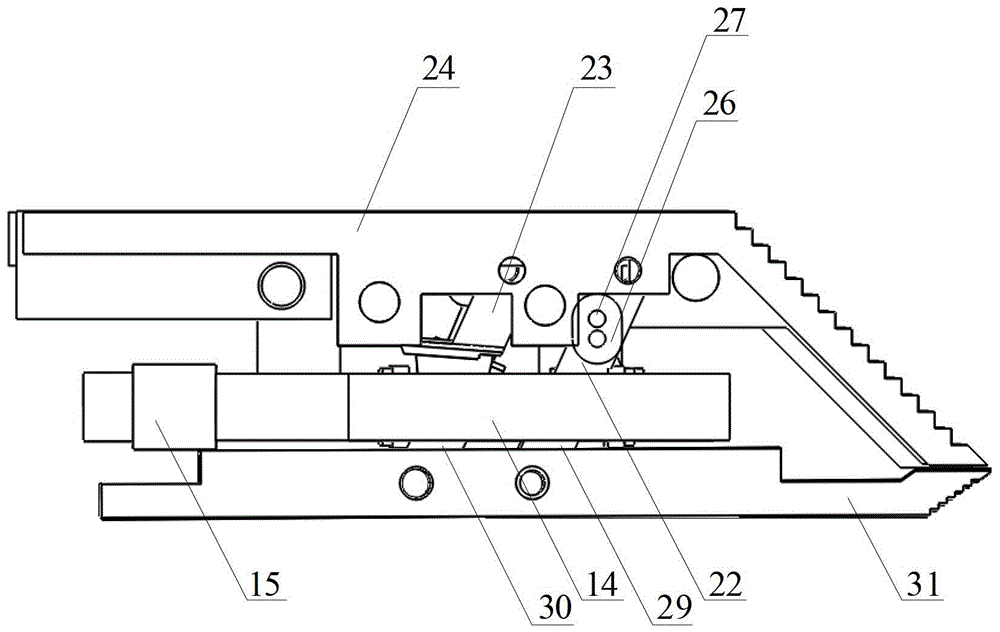

[0031] The seam starting mechanism is installed in the shell 2, based on the fixed frame 14 fixedly connected with the shell 2 by screws. The seam starting mechanism includes a motor assembly, a lead screw nut assembly, an upper seam starting mechanism and a lower seam starting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com