Oil tank and motorcycle thereof

A technology for motorcycles and fuel tanks, applied in gasoline drums, bicycle accessories, transportation and packaging, etc., can solve the problems of water splashing, fuel pollution, and inability to take into account drainage, etc., to achieve good drainage effects and ensure clean and hygienic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

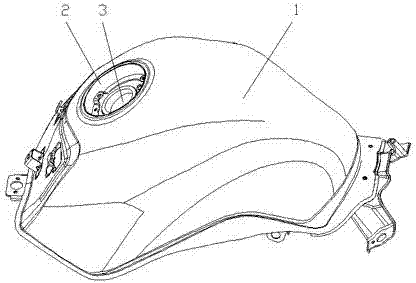

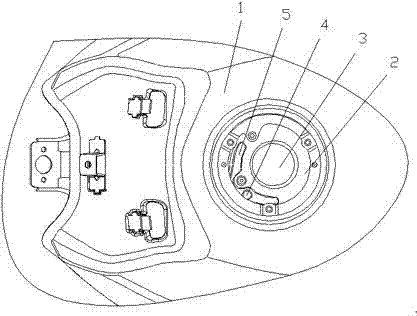

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 As shown in the figure: the fuel tank of this embodiment includes a fuel tank body 1, the fuel tank body 1 is provided with a sinker 2 for installing the fuel tank cap, and the bottom surface of the sinker 2 is provided with an oil inlet 3 and Water leakage port 4; the bottom surface of the sinking tank 2 corresponds to the water leakage port 4 and is provided with a drainage groove 5; the drainage groove 5 is a groove with the depth gradient at the lowest point where the water leakage port 4 is located, and the oil inlet and the water leakage port correspond to each other. Arranged adjacently and between the oil inlet and the water leakage port, there is an annular boss (not shown in the figure); a drain pipe (not shown in the figure) that runs through the fuel tank body 1 and connects the water leakage port 4 to the outside is fixed under the sinker 2 use the guiding fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com