Contact lens care preparation and packaging solution

A contact lens and packaging solution technology, applied in glasses/goggles, glasses/protective glasses, packaging, etc., can solve the problems of not inspecting the lubricity of the lens surface and insufficient effect, and achieve the purpose of inhibiting amoeba adhesion and durability The effect of surface lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The present invention will be described in more detail below based on the examples, but these are not intended to limit the present invention.

[0072] In addition, various measurements in the examples were performed as follows.

[0073]

[0074] 5 mg of the obtained polymer was dissolved in 1 g of methanol / chloroform mixed solvent (8 / 2, volume ratio) to prepare a sample solution. Other conditions are described below.

[0075] Column: PLgel-mixed-C, standard substance: polyethylene glycol, detection: parallax refractometer RI-8020 (manufactured by Tosoh Corporation), calculation of weight average molecular weight (Mw): molecular weight calculation program (SC-8020 with GPC program), flow rate 1ml / min, sample solution injection volume: 100μl, column temperature 40°C.

[0076] The number average molecular weight of a polymer is the value of the number average molecular weight measured by gel permeation chromatography (GPC) using polyethylene glycol as a standard sampl...

Synthetic example 1-1

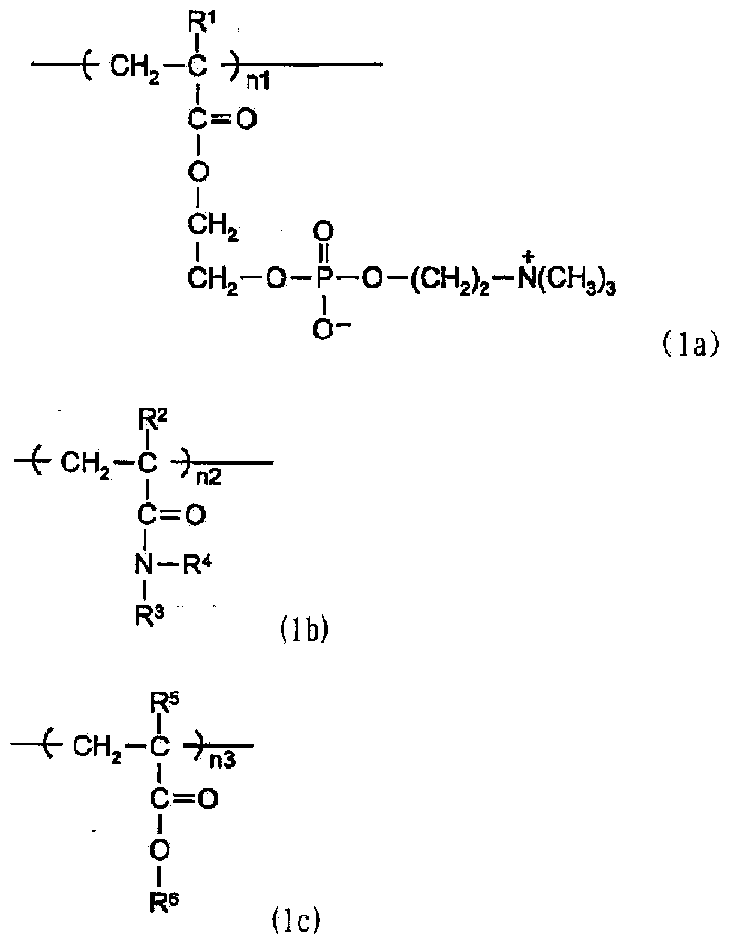

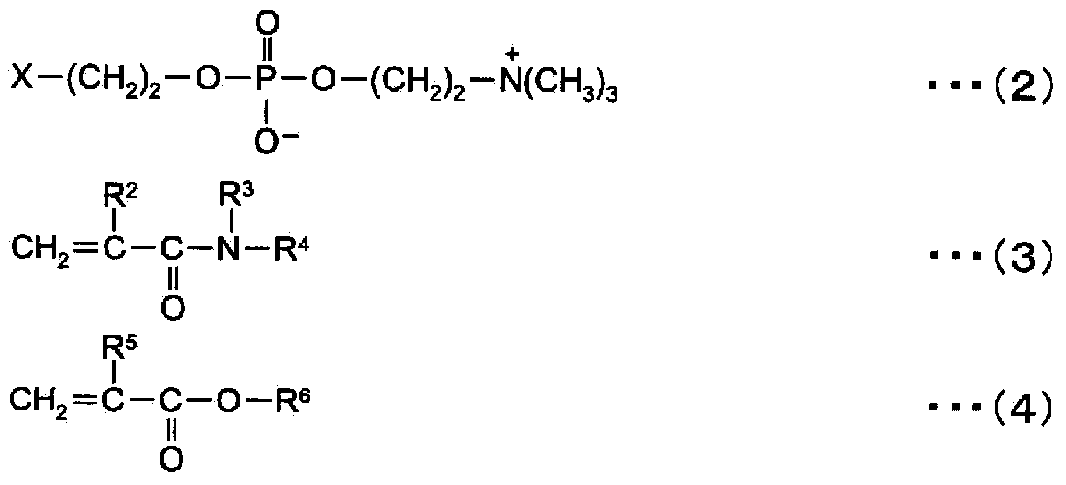

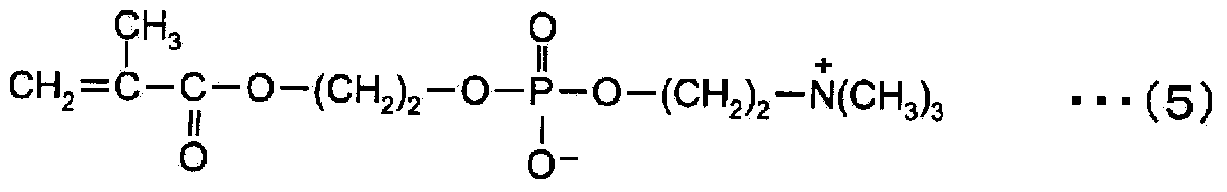

[0109] Synthesis Example 1-1 (Polymer A-1; MPC0.50-SMA0.05-DMAA0.45)

[0110] 31.75g of MPC (manufactured by NOF Corporation), 3.64g of stearate methacrylate (SMA, manufactured by NOF Corporation) and 9.60g of N,N-dimethylacrylamide (DMAA, Xingren company) was dissolved in 55.0 g of ethanol, put into a four-necked flask, and blown with nitrogen for 30 minutes. Then, 0.10 g of a product name "PERBUTYL ND" (manufactured by NOF Corporation) (hereinafter abbreviated as PB-ND) was added at 50° C., and a polymerization reaction was performed for 8 hours. The polymerization solution was dripped into 3 liters of diethyl ether while stirring, and the precipitated precipitate was filtered and vacuum-dried at room temperature for 48 hours to obtain 40.2 g of powder. The molecular weight evaluated by GPC was a weight average molecular weight of 1,000,000. Let this be polymer A-1. The data of IR, NMR, and elemental analysis are shown below.

[0111] IR data: 2964cm -1 (-CH), 1733cm ...

Synthetic example 1-2

[0117] Synthesis Example 1-2 (Polymer A-2; MPC0.30-SMA0.03-DMAA0.67)

[0118] 24.13 g of MPC, 2.77 g of SMA and 18.11 g of DMAA were dissolved in 55.0 g of n-propanol, put into a four-neck flask, and blown with nitrogen for 30 minutes. Then, 0.10 g of PB-ND was added at 50° C., and a polymerization reaction was performed for 8 hours. The polymerization solution was dripped into 3 liters of diethyl ether while stirring, and the precipitated precipitate was filtered and vacuum-dried at room temperature for 48 hours to obtain 42.4 g of powder. The molecular weight evaluated by GPC was a weight average molecular weight of 1,200,000. Let this be polymer A-2. The data of IR, NMR, and elemental analysis are shown below.

[0119] IR data: 2964cm -1 (-CH), 1733cm -1 (O-C=O), 1651cm -1 (N-C=O), 1458cm -1 (-CH), 1253cm -1 (P=O), 1168cm -1 (C-O-C), 997cm -1 (P-O-C).

[0120] NMR data: 0.8-1.2ppm (CH3 -C-), 1.4ppm (-CH 2 -),3.3ppm(-N(CH 3 ) 3 ), 2.8-3.2ppm (-N-(CH 3 ) 2 ), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com