Rotor wire end merging and cutting-off all-in-one machine

A rotor wire, all-in-one technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of insufficient accuracy, unsuitable production mode, single function, etc., to increase work efficiency, save labor costs, The effect of improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

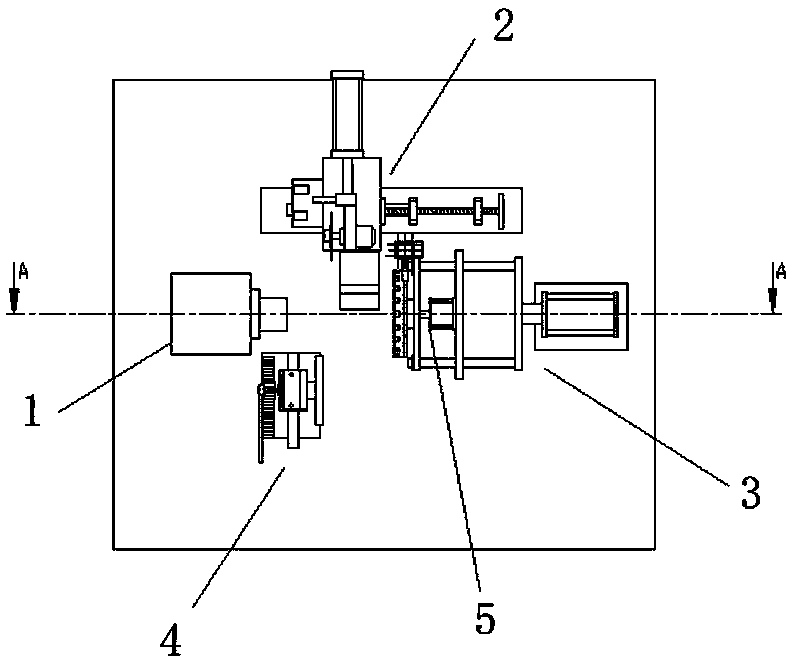

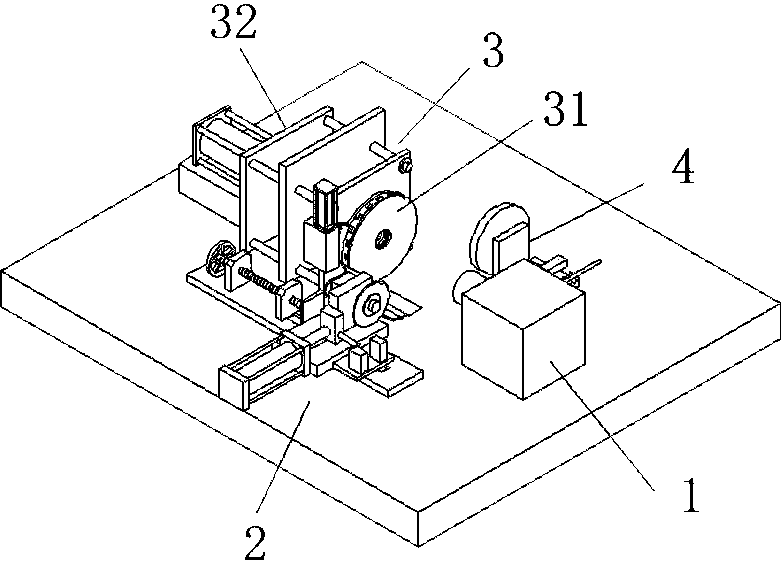

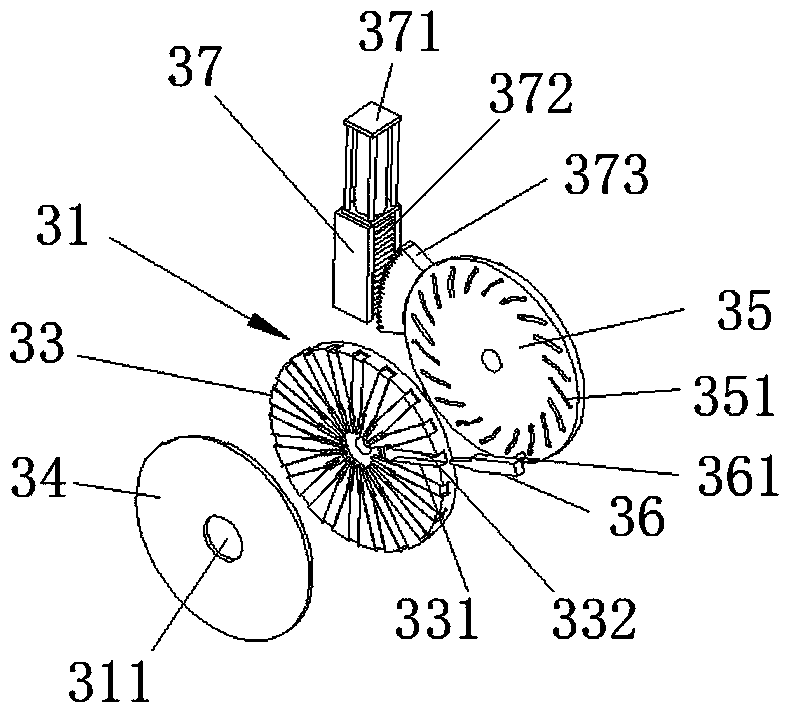

[0031] Example 1, such as Figure 1-2As shown, an integrated machine for paralleling and cutting rotor wire ends, including a rotating fixing device 1 for fixing one end of the rotor and driving the rotor to rotate, an ejecting device 5 for fixing the other end of the rotor, and a device for incorporating the coil into the exchange The inserting device 3 of the directing device slot and the cutting device 2 for cutting off the excess coil ends; the inserting device 3 includes a pin insertion device 31 and a moving device for changing the distance between the pin insertion device 31 and the rotating and fixing device 1 32. The ejecting device 5 is arranged in the moving device 32, which can greatly reduce the volume of the whole equipment and speed up the transmission efficiency. The rotating and fixing device 1 includes a motor and a rotating and fixing shaft, the rotating and fixing shaft is used for connecting one end of the rotor, and the motor is used for driving the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com