Spiral steel pipe with reinforcing rings and manufacturing method of spiral steel pipe

A technology of spiral steel pipe and manufacturing method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of easy leakage, difficult processing, and not too large caliber, so as to enhance the hoop strength and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below.

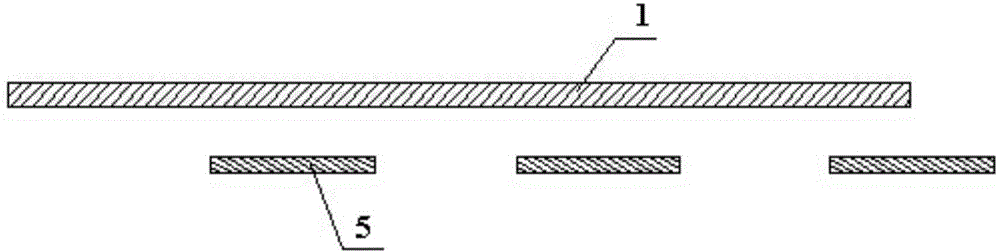

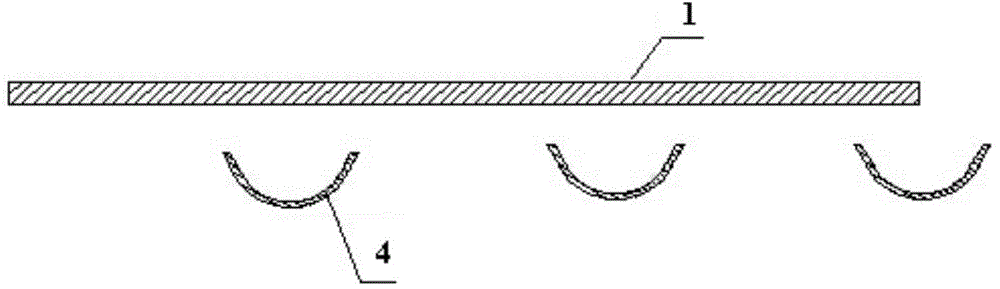

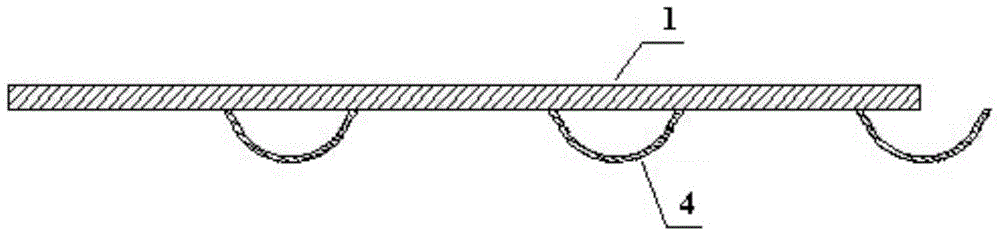

[0028] Such as Figure 1-3 As shown, according to the diameter of the produced spiral welded steel pipe, adjust the forming angle of the spiral pipe shaping machine to an appropriate value. After the narrow steel strip 5 is unwound, leveled, trimmed and other processes, press figure 1 The positions shown are arranged. In this embodiment, the narrow steel strip 5 is placed under the main steel strip 1, so that a spiral steel pipe with a reinforcing ring on the outer wall can be produced. If the narrow steel strip 5 is placed above the main steel strip 1, then Spiral steel pipes with reinforcing rings on the inner wall can be produced. Narrow steel band 5 passes through bending mechanism again, is bent into the reinforcement ring 4 that cross-section is arc shape (present embodiment, also can be trapezoidal, square etc. of course), as figure 2 shown. Then the reinforcement ring 4 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com