A method for retaining false roofs in layers in coal mining face with solid filling

A coal mining face and solid filling technology, which is applied in the field of coal mining with layered and false roofs, can solve problems such as thick, unstable and false roofs, and achieve scientific and engineering significant results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

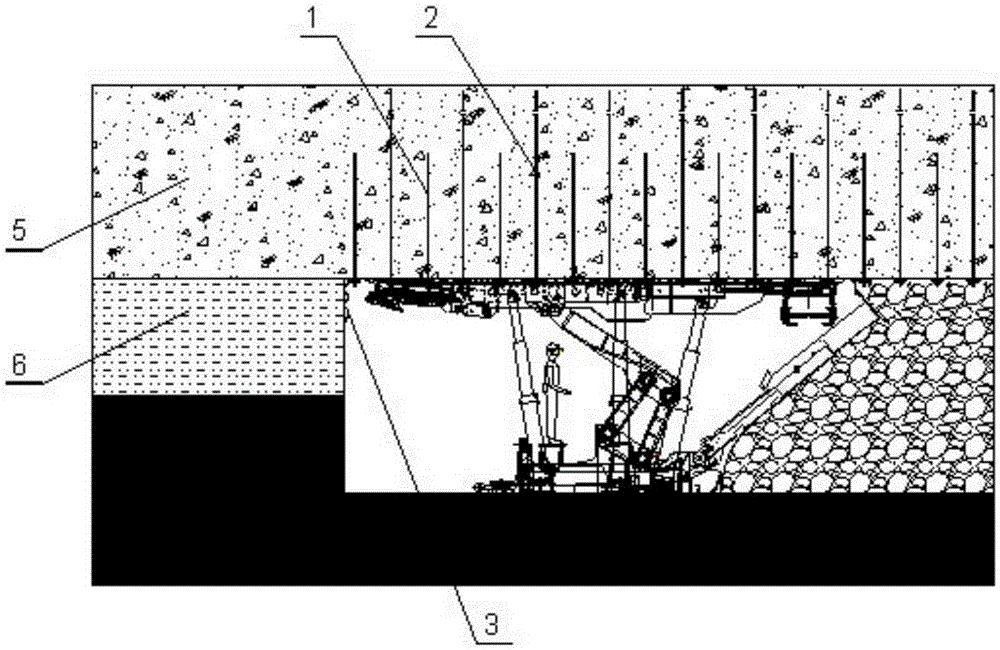

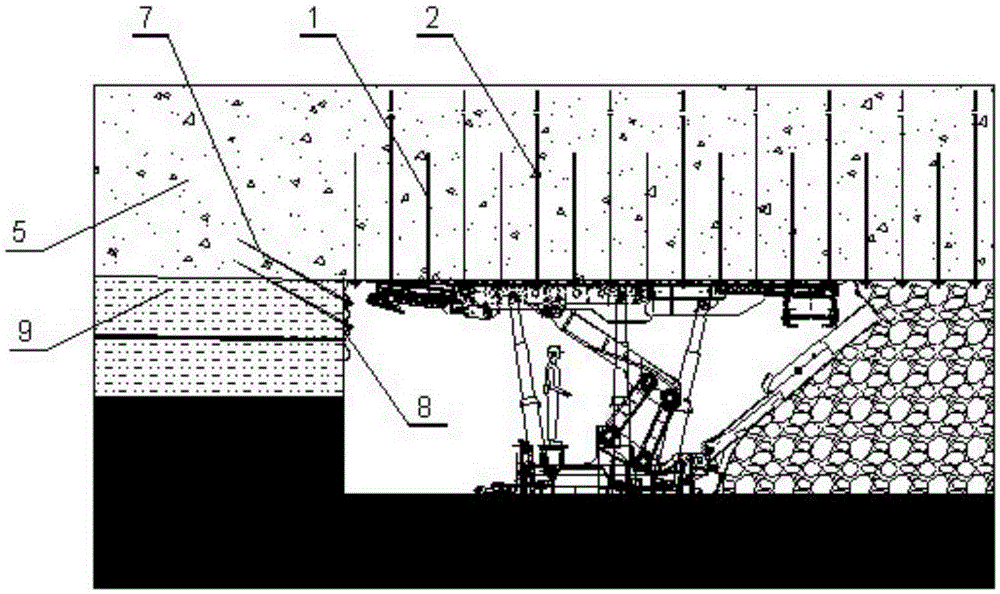

[0035] Embodiment 1, general situation of working face

[0036] A solid filling coal mining face has a strike length of 150m and a dip length of 1198m. The average thickness of coal in the main mining seam 8 is 2.6m, and the average dip angle is 7°; the immediate roof of the coal seam is relatively hard fine-grained sandstone, and the floor is gray-black silty mudstone; The pseudo-roof of sandy mudstone is stabilized and falls with mining; the method of "retaining the roof in layers and gradually increasing it" is adopted in the working face to retain the pseudo-roof.

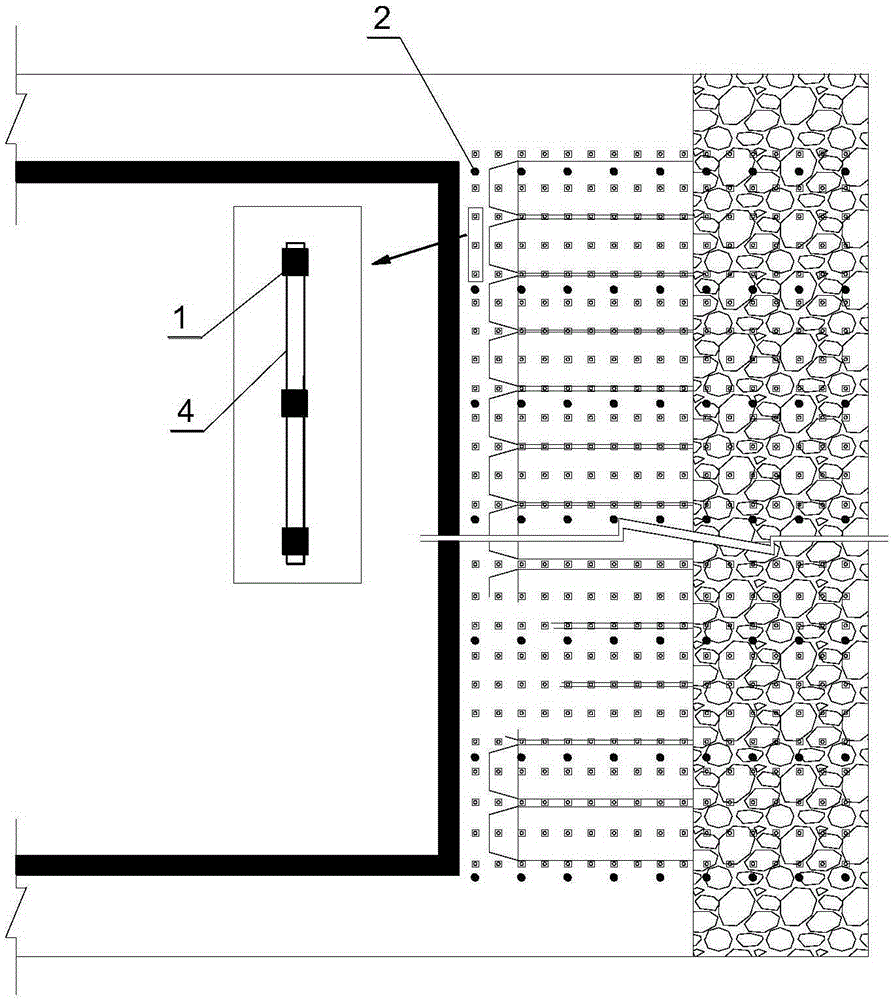

[0037] The process of "retaining the top layer by layer and increasing gradually" is as follows:

[0038] The first step is to strengthen the support of the roof before retaining the false roof:

[0039] Before leaving the false roof, after the coal cutting of the working face is completed, the entire working face in front of the support is suspended by means of joint support of "bolt a1 + anchor cable 2 + me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com