Porous electric heating recyclable anchorage device combined type component and construction method using same

An electrothermal fusion, combined technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of low single anchor bearing capacity, high economic cost, low recovery rate, etc., to improve bearing capacity and large foundation area. , the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

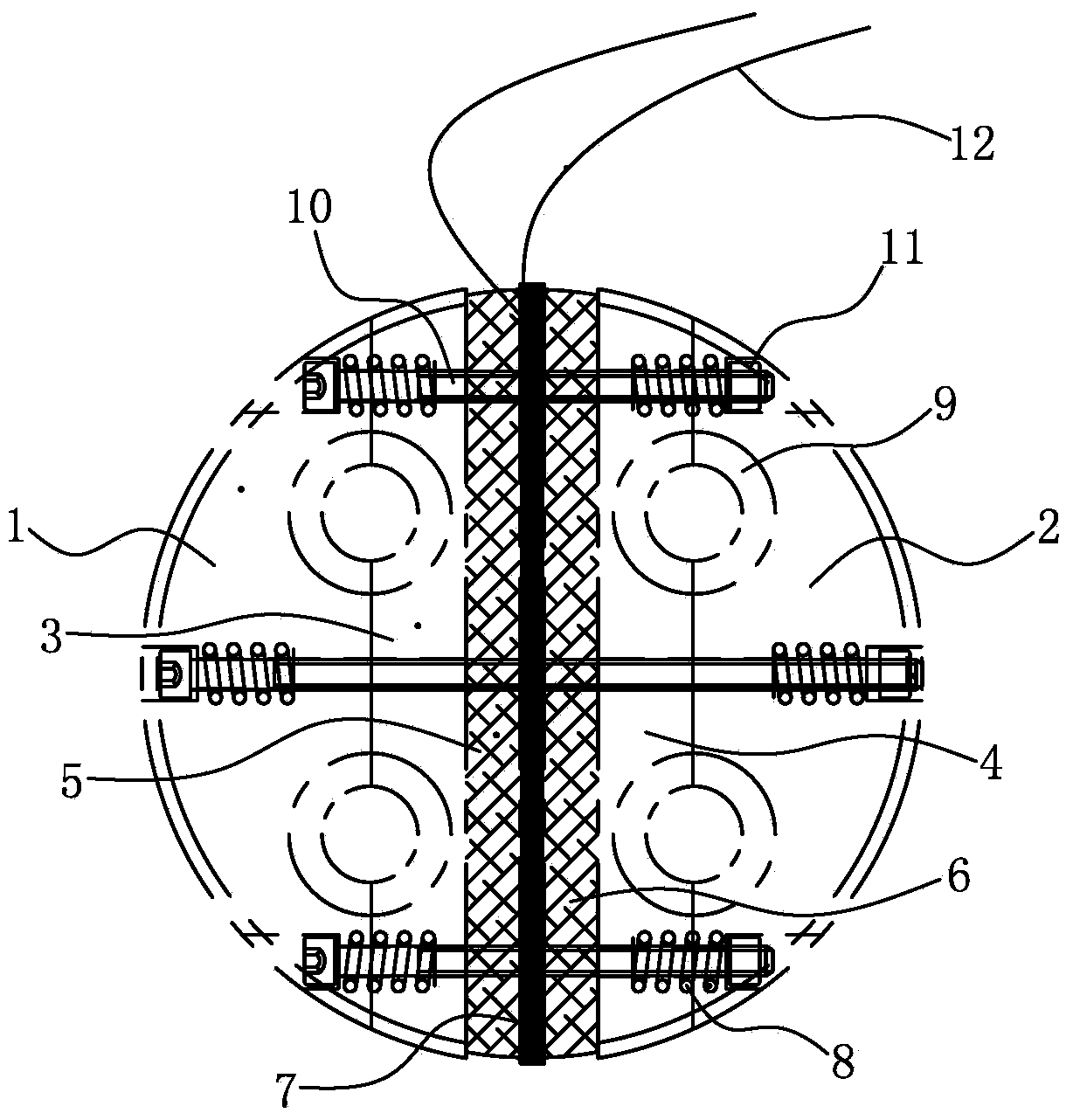

[0036] Such as Figure 1~4 As shown, the porous electrothermal fusion recyclable anchor composite component of the present invention includes a first outer locking plate 1 and a second outer locking plate 2, and a first inner locking plate is arranged between the first and second outer locking plates 1 and 2. The core support plate 3 and the second inner core support plate 4, the first and second inner core support plates 3, 4 are arranged close to the first and second outer locking plates 1, 2 respectively, and are supported on the first and second inner cores Between the boards 3 and 4, there are a first electrothermally fused high-strength plastic plate 5 and a second electrothermally fused high-strength plastic plate 6, and the first and second electrothermally fused high-strength plastic plates 5 and 6 are respectively close to the first and second inner core support plates 3 and 4 are set, the first and second electric hot-melt high-strength plastic plates 5 and 6 are pr...

Embodiment 2

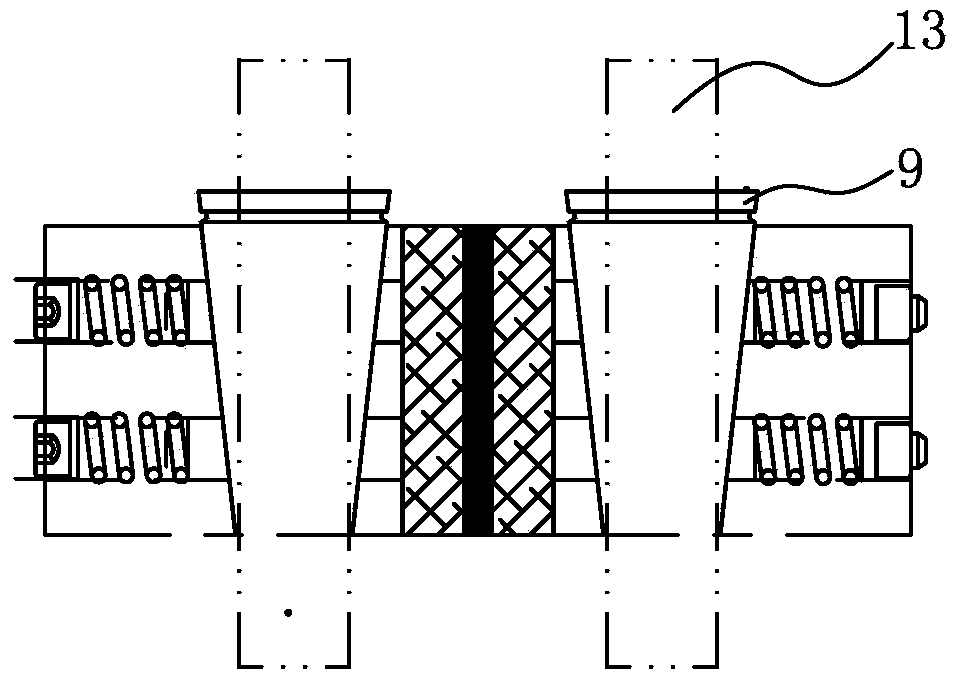

[0050] Such as Figure 5 , Figure 7 with Figure 12 As shown, the porous electrothermal fusion recyclable anchor composite component of the present invention includes a first outer locking plate 1 and a second outer locking plate 2, and a first inner locking plate is arranged between the first and second outer locking plates 1 and 2. The core support plate 3 and the second inner core support plate 4, the first and second inner core support plates 3, 4 are arranged close to the first and second outer locking plates 1, 2 respectively, and are supported on the first and second inner cores Between the boards 3 and 4, there are a first electrothermally fused high-strength plastic plate 5 and a second electrothermally fused high-strength plastic plate 6, and the first and second electrothermally fused high-strength plastic plates 5 and 6 are respectively close to the first and second inner core support plates 3 and 4 are set, the first and second electric hot-melt high-strength p...

Embodiment 3

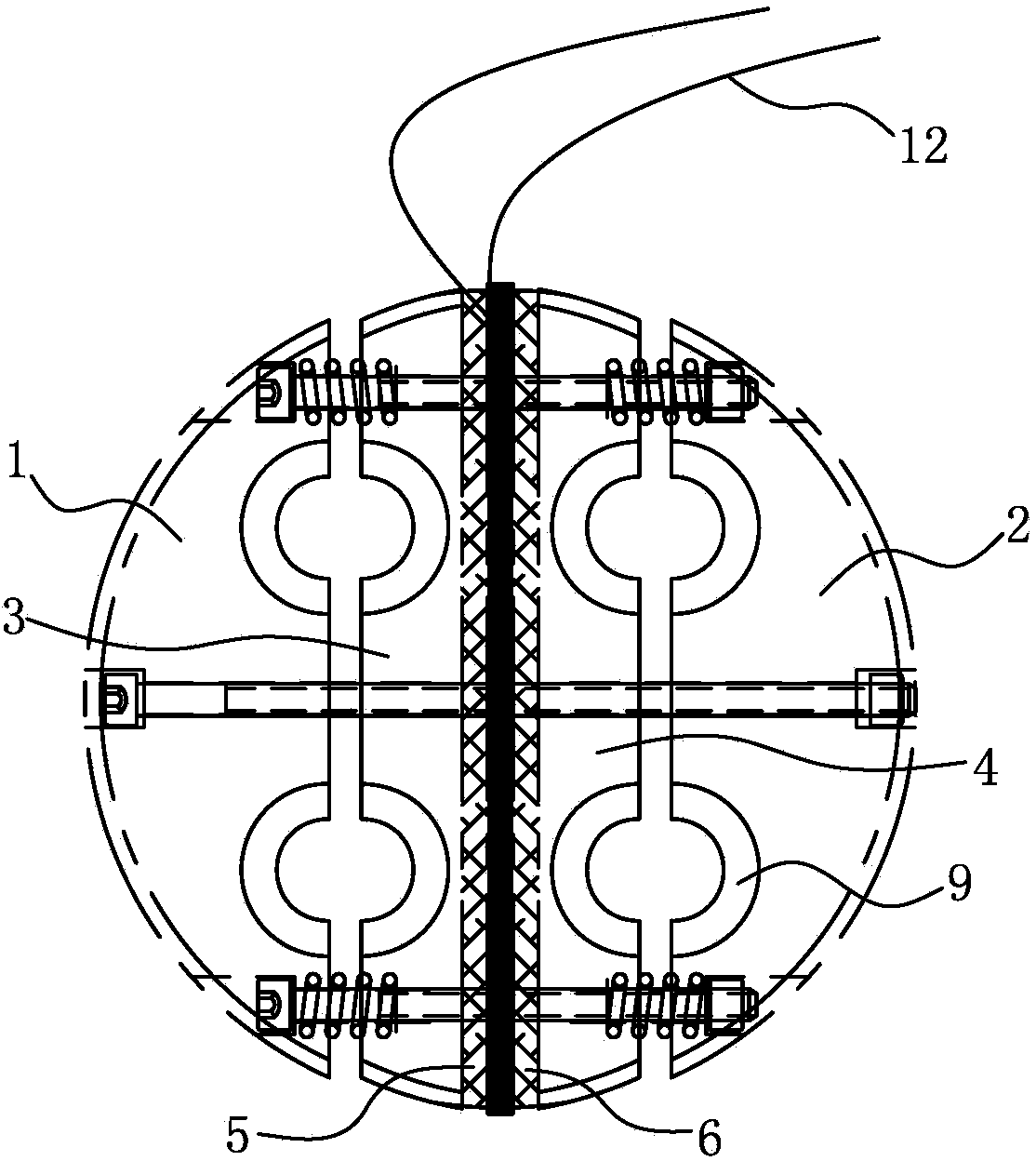

[0065] Such as Image 6 , Figure 8 with Figure 10 As shown, the porous electrothermal fusion recyclable anchor composite component of the present invention includes a first outer locking plate 1 and a second outer locking plate 2, and a first inner locking plate is arranged between the first and second outer locking plates 1 and 2. The core support plate 3 and the second inner core support plate 4, the first and second inner core support plates 3, 4 are arranged close to the first and second outer locking plates 1, 2 respectively, and are supported on the first and second inner cores Between the boards 3 and 4, there are a first electrothermally fused high-strength plastic plate 5 and a second electrothermally fused high-strength plastic plate 6, and the first and second electrothermally fused high-strength plastic plates 5 and 6 are respectively close to the first and second inner core support plates 3 and 4 are set, the first and second electric hot-melt high-strength pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com