Method for fermenting and preparing dendrobium huoshanness vinegar by taking processing excess material of rice and sugarcane as raw material

A technology of Dendrobium huoshanense and fermented vinegar, which is applied in the fields of preparing vinegar by fermentation and preparing Dendrobium huoshanense vinegar by fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

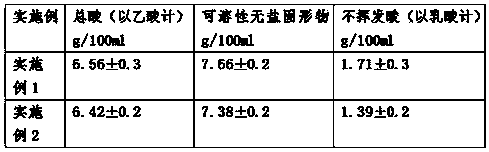

Examples

Embodiment 1

[0022] ①Weigh 1000g of the cleaned processing residue, which is broken rice, rice bran, and sugarcane pomace with a mass ratio of 100:20:100, and place it in a pulverizer for primary crushing, with a particle size of less than 0.1 cm, and then mixed with 3L water;

[0023] 2. In the self-priming fermenter, add 200g compound enzyme in the mixture that step 1. obtains, and described compound enzyme is α-amylase, cellulase and hemicellulase that mass ratio is 100:100:50, in Ferment at 55°C and pH 5.0±0.2 for 10 hours to obtain liquefied mash;

[0024] ③In a self-priming fermenter, add 40g of glucoamylase to the liquefied mash obtained in step ②, and ferment for 5 hours at 60°C and pH4.2±0.2 to obtain saccharified mash;

[0025] ④In a self-priming fermenter, add 40g of active dry yeast to the saccharified mash obtained in step ③ to carry out alcoholic fermentation, and ferment for 5 days under the conditions of 35°C and pH3.8±0.2 to obtain the saccharified mash;

[0026] ⑤In the...

Embodiment 2

[0033] ①Weigh 1000g of the cleaned processing residue, which is broken rice, rice bran, and sugarcane pomace with a mass ratio of 100:10:50, and place it in a pulverizer for primary crushing, with a particle size of less than 0.1 cm, and then mixed with 3L water;

[0034] 2. In the self-priming fermenter, add 100g compound enzyme in the mixture that step 1. obtains, and described compound enzyme is α-amylase, cellulase and hemicellulase that mass ratio is 100:50:10, in Ferment at 60°C and pH 5.0±0.2 for 8 hours to obtain liquefied mash;

[0035] ③In a self-priming fermenter, add 20g of glucoamylase to the liquefied mash obtained in step ②, and ferment for 8 hours at 65°C and pH4.2±0.2 to obtain saccharified mash;

[0036] ④In a self-priming fermenter, add 30g of active dry yeast to the final saccharified mash obtained in step ③ for alcoholic fermentation, and ferment for 3 days at 37°C and pH 3.8±0.2 to obtain the saccharified mash;

[0037] 5. In the self-priming fermenter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com