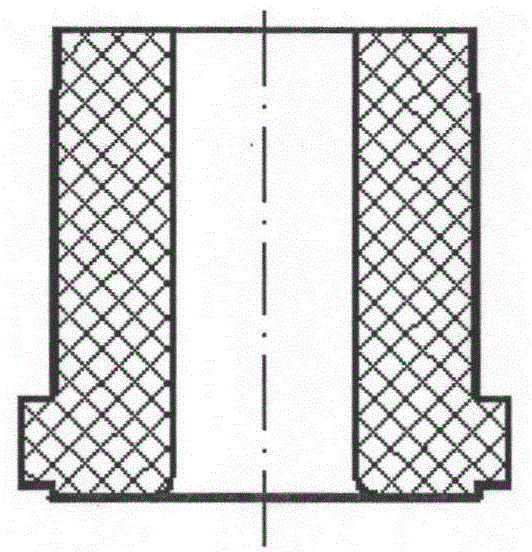

A kind of rubber composition of leaf spring lug bushing for automobile

A technology of rubber composition and leaf spring, which is applied in the field of rubber chemical industry, can solve the problems of poor extrusion resistance, easy failure and damage, etc., and achieve the effect of better surface brightness, low price, and convenient use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

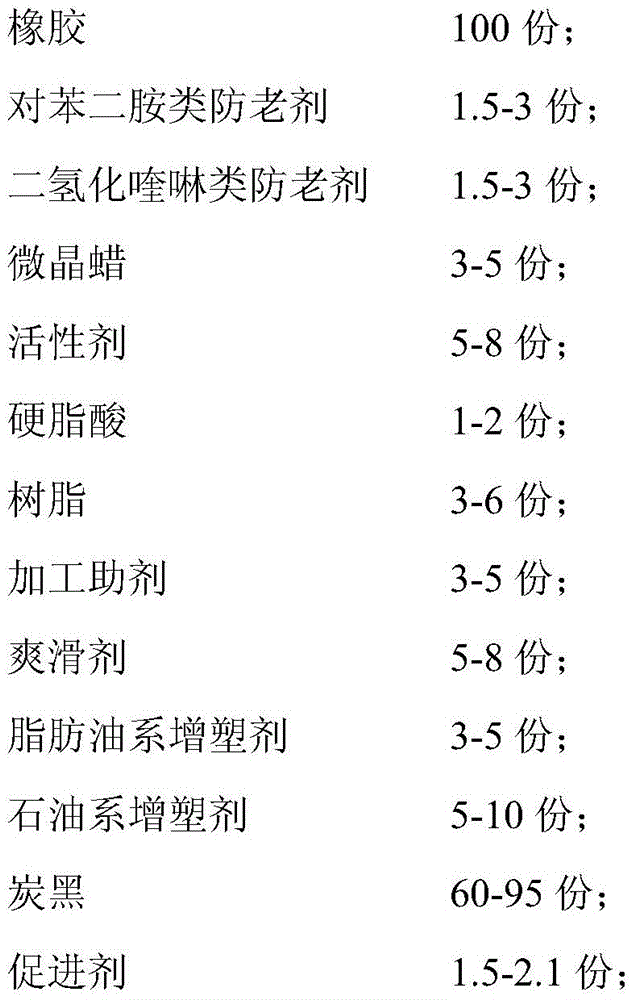

[0026] A rubber composition for a leaf spring lug bushing for automobiles, comprising the following components in parts by weight:

[0027] SCR5: 50 copies;

[0028] SBR1502: 50 copies;

[0029] Active zinc oxide: 8 parts;

[0030] Stearic acid: 2 parts;

[0031] Anti-aging agent 4010NA: 3 parts;

[0032] Anti-aging agent RD: 2 parts;

[0033] ANTILUX654: 4 copies;

[0034] Coumarone: 6 copies;

[0035] STRUKTOLWB215: 4 copies;

[0036] Black ointment: 3 parts;

[0037] CrodamidesVRX: 8 copies;

[0038] N-330: 40 copies;

[0039] N-774: 30 copies;

[0040] Aromatic oil: 5 parts;

[0041] Accelerator CZ: 1.5 parts;

[0042] Accelerator DM: 0.4 parts;

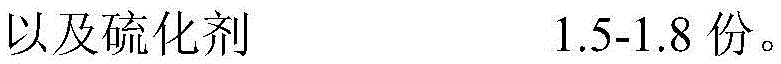

[0043] And IS60: 1.6 copies.

[0044] The preparation method uses a kneader to mix, and the steps are as follows:

[0045] Raise the temperature of the kneader to 110°C, put the rubber into the mixing chamber and knead for 40s, then lift the top plug to add a section of fine materials: active agent, stearic acid, antioxidant, microcrystalline wax, resin...

Embodiment 2

[0047] A rubber composition for a leaf spring lug bushing for automobiles, comprising the following components in parts by weight:

[0048] SCR5: 60 copies;

[0049] SBR1502: 40 copies;

[0050] Active zinc oxide: 7 parts;

[0051] Stearic acid: 1.5 parts;

[0052] Anti-aging agent 4010NA: 2 parts;

[0053] Anti-aging agent RD: 3 parts;

[0054] ANTILUX654: 5 copies;

[0055] Coumarone: 5 copies;

[0056] STRUKTOLWB215: 5 copies;

[0057] Black ointment: 5 parts;

[0058] CrodamidesVRX: 7 copies;

[0059] N-330: 50 copies;

[0060] N-774: 40 copies;

[0061] Aromatic oil: 10 parts;

[0062] Accelerator CZ: 1.6 parts;

[0063] Accelerator DM: 0.5 parts;

[0064] And IS60: 1.8 copies.

[0065] The preparation method is the same as in Example 1.

Embodiment 3

[0067] A rubber composition for a leaf spring lug bushing for automobiles, comprising the following components in parts by weight:

[0068] SCR5: 70 copies;

[0069] SBR1502: 30 copies;

[0070] Active zinc oxide: 6 parts;

[0071] Stearic acid: 1.5 parts;

[0072] Anti-aging agent 4010NA: 2 parts;

[0073] Anti-aging agent RD: 2 parts;

[0074] ANTILUX654: 3 copies;

[0075] Coumarone: 4 copies;

[0076] STRUKTOLWB215: 3 copies;

[0077] Black ointment: 3 parts;

[0078] CrodamidesVRX: 5 copies;

[0079] N-330: 30 copies;

[0080] N-774: 30 copies;

[0081] Aromatic oil: 5 parts;

[0082] Accelerator CZ: 1.2 parts;

[0083] Accelerator DM: 0.3 parts;

[0084] And IS60: 1.5 copies.

[0085] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com