Method and device for dehydrating and refining biofuel

A biofuel and biological technology, applied in the fields of biofuels, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of waste of energy consumption, reduce the relative volatility of alcohol and water, and reduce the efficiency of rectification and separation, and achieve huge market applications. Prospects, high relative volatility, and the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Dehydration and refining of ethanol fermentation broth

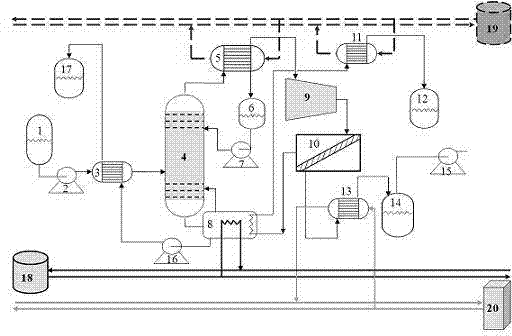

[0017] use figure 1 The shown device dehydrates and refines the ethanol fermentation liquid. The dehydration process is as follows:

[0018] Put the ethanol fermentation liquid with a water content of 92wt.% into the raw material tank 1, and under the promotion of the feed pump 2, preheat the fermented liquid in the raw material tank 1 through the preheater 3 to 78 ~ After 85°C, it is sent to the rectification tower 4. The total number of trays in the rectification tower is 12, and the feeding position is the 10th theoretical plate. The reboiler 8 maintains a tower bottom temperature of 95-105° C. under the heat supply conditions of the saturated water vapor from the steam boiler 18 and the anhydrous alcohol vapor on the retentate side of the steam permeation membrane separation unit 10; meanwhile, the rectification tower 4 The top of the tower is controlled to be 70-80°C by condensing the reflux...

Embodiment 2

[0019] Example 2 Dehydration and purification of ethanol fermentation broth with a water content of 95wt.%.

[0020] Present embodiment is that water content is its refining process with embodiment 1, and difference with embodiment 1 is:

[0021] The raw material is fermented liquid ethanol with a water content of 95wt.%.

[0022] The total number of plates in the rectification tower is 12, and the feeding position is the fifth theoretical plate;

[0023] Fermentation broth preheating temperature 80 ~ 90 ℃;

[0024] The flow rate of feed pump 2 is 20000kg / h;

[0025] The top reflux ratio is 2.8~3.5;

[0026] The temperature at the top of the tower is controlled at 85-95°C;

[0027] The temperature of the tower kettle is controlled at 100-110°C;

[0028] The water content in the uncondensed gas through the partial condenser 5 is 20 wt.%;

[0029] Compressor pressure increased by 0.5Mpa (gauge pressure);

[0030] The vacuum pressure on the permeate side is 1500Pa;

[003...

Embodiment 3

[0033] Example 3 Dehydration and purification of butanol fermentation broth

[0034] The present embodiment refining process is the same as embodiment 1, and difference with embodiment 1 is:

[0035] The raw material is a butanol fermentation broth with a water content of 98wt.%.

[0036] The total number of trays in the rectification tower is 20, and the feed position is the 10th theoretical tray;

[0037] The preheating temperature of the fermentation broth is 80-90°C;

[0038] The flow rate of feed pump 2 is 25000kg / h;

[0039] The top reflux ratio is 1~3.5;

[0040] The temperature at the top of the tower is controlled at 85-95°C;

[0041] The temperature of the tower kettle is controlled at 100-110°C;

[0042] The water content in the uncondensed gas through the partial condenser 5 is 30 wt.%;

[0043] Compressor pressure increased by 0.5Mpa (gauge pressure);

[0044] The vacuum pressure on the permeate side is 1300Pa;

[0045] The steam permeation membrane separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com