Self-supported graphene hydrogel membrane and preparation method thereof

A graphene hydrogel and self-supporting technology, which is applied in the field of hydrogel membrane and its preparation, can solve the problems of structural damage, limited suction filtration equipment, and inability to obtain large areas, and achieves low cost, simple process, The effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

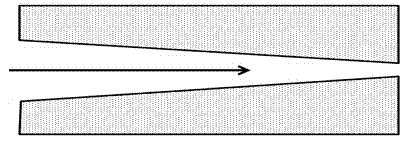

[0023] The preparation method of self-supporting graphene hydrogel film comprises the following steps:

[0024] 1) Mix 1 part by weight of graphene oxide and 50-200 parts by weight of water, and ultrasonically disperse to obtain an aqueous dispersion of graphene oxide;

[0025] 2) Extrude the aqueous dispersion of graphene oxide obtained in step 1) into the coagulation liquid at an extrusion speed of 10-1000 mL / h in a device with a straight die, and solidify into graphite oxide after staying for 1-100 seconds ene hydrogel film;

[0026] 3) 1 part by weight of the graphene oxide hydrogel film obtained in step 2) is chemically reduced with 1 to 200 parts by weight of a reducing agent at 60 to 120 ° C for 1 min to 24 hours, and then washed with water to obtain self-supporting graphite ene hydrogel film; or put 1 part by weight of the graphene oxide hydrogel film obtained in step 2) into a hydrothermal kettle for hydrothermal reduction at 120-250°C for 1-36h, and then wash with w...

Embodiment 1

[0033] 1) The graphene oxide of 1 weight part, the water of 50 weight parts are mixed, obtain the aqueous dispersion liquid of 20mg / mL graphene oxide after ultrasonic dispersion;

[0034] 2) Extrude the aqueous dispersion obtained in step 1) into the coagulation liquid in a device with an inline die at an extrusion speed of 10 mL / h, and stay for 1 second to solidify into a graphene oxide hydrogel film;

[0035] 3) 1 part by weight of the graphene oxide hydrogel film obtained in step 2) is chemically reduced with 1 part by weight of hydrazine at 95°C for 1 hour, soaked in deionized water for 24 hours, and the graphene hydrogel film is taken out , to obtain a self-supporting graphene hydrogel membrane.

[0036] After the above steps, the self-supporting graphene hydrogel film has a thickness of 1000 μm, a water content of 100%, and a conductivity of 0.2×10 7 S / m, the tensile strength is 80MPa.

Embodiment 2

[0038] 1) The graphene oxide of 1 weight part, the water of 200 weight parts are mixed, obtain the aqueous dispersion liquid of 5 mg / mL graphene oxide after ultrasonic dispersion;

[0039] 2) Extrude the aqueous dispersion obtained in step 1) into the coagulation liquid in an inline die device at an extrusion speed of 1000 mL / h, and solidify into a graphene oxide hydrogel film after staying for 1 second;

[0040] 3) 1 part by weight of the graphene oxide hydrogel film obtained in step 2) is chemically reduced with 10 parts by weight of hydroiodic acid at 95° C. for 1 hour, soaked in deionized water for 12 hours, taken out, and then deionized Soaking in water for 12 hours was repeated 3 times to obtain a self-supporting graphene hydrogel film.

[0041] After the above steps, the self-supporting graphene hydrogel film has a thickness of 100nm, a water content of 70%, and a conductivity of 0.5×10 9 S / m, the tensile strength is 120MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com