Powder feeding mechanism for preventing pollution to cefodizime sodium used for injection

A technology for cefodizime sodium and injection, which is applied in the field of powder feeding mechanism to prevent the pollution of cefodizime sodium for injection, and can solve the problems of affecting the quality of the finished drug powder, pollution of clean drug powder, and blockage of the transmission mechanism by the drug powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

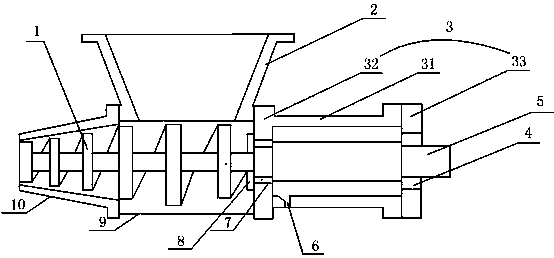

[0026] Such as figure 1 As shown, a powder feeding mechanism for preventing contamination of cefodizime sodium for injection includes a powder feeding hopper 2, a powder feeding cylinder 9, a powder outlet 10 and a transmission part; The top of the cylinder 9 is connected with the powder feeding cylinder 9; the left side of the powder feeding cylinder 9 is connected with the powder outlet 10, and the powder outlet 10 is a conical cylinder with the left opening smaller than the right opening; the powder feeding The right side of the cylinder 9 is provided with a transmission part, and the powder feeding cylinder 9 is provided with a powder feeding screw 1, and the right side of the powder feeding screw 1 is connected with the transmission part; there is also a flexible connection between the powder feeding cylinder 9 and the transmission part A support device 3 with an internal cavity to prevent powder from intruding into the transmission part. The support device 3 includes a s...

Embodiment 2

[0029] Such as figure 1 As shown, similar to Embodiment 1, a powder metallurgy oil-impregnated bearing 7 is also provided at the gap between the support base 32 and the transmission shaft. The thermal expansion coefficients of porous materials and lubricating oil are different, so the oil is squeezed into the friction surface from the pores when it is working, and the oil is sucked back into the pores as the temperature drops when it stops working. Powder metallurgy oil-impregnated bearing 7 has the characteristics of low cost, vibration absorption, low noise, and no need to add lubricating oil during a long working time. It is especially suitable for working environments that are not easy to lubricate or do not allow oil to be dirty.

[0030] An annular sheet 8 is also arranged between the powder feeding screw 1 and the support base 32 to prevent the powder from entering the support device 3 . The arrangement of the powder metallurgy oil bearing 7 and the annular piece 8 can...

Embodiment 3

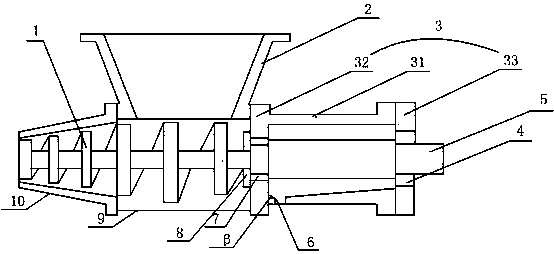

[0032] Such as figure 2 As shown, similar to Example 1, a stirring paddle is also provided in the powder feeding hopper, and the stirring paddle is driven by a motor. The stirring paddle is set in the powder feeding hopper, the purpose is to make the powder not easy to agglomerate.

[0033] The transmission shaft 5 is also provided with an electromagnetic clutch to control the movement of the powder feeding screw 1 and then control the powder level.

[0034] The support cylinder 31 is also provided with a powder discharge hole 6 penetrating through the support cylinder 31 for discharging the powder reaching the inner cavity of the support device 3 .

[0035] The powder leaking hole 6 is arranged near the support base 32, and the powder leaking hole 6 is funnel-shaped. The setting of the powder discharge hole 6 can discharge the powder without dismantling the support device 3 , preventing excessive powder accumulation in the support device 3 and causing possible pollution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com