Printing device

A technology of printing device and transmission device, which is applied in the field of printing device, can solve problems such as loose relative position, improper forming, failure, etc., and achieve the effects of uniform force application, fastening and disassembly, and guaranteed forming quality and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

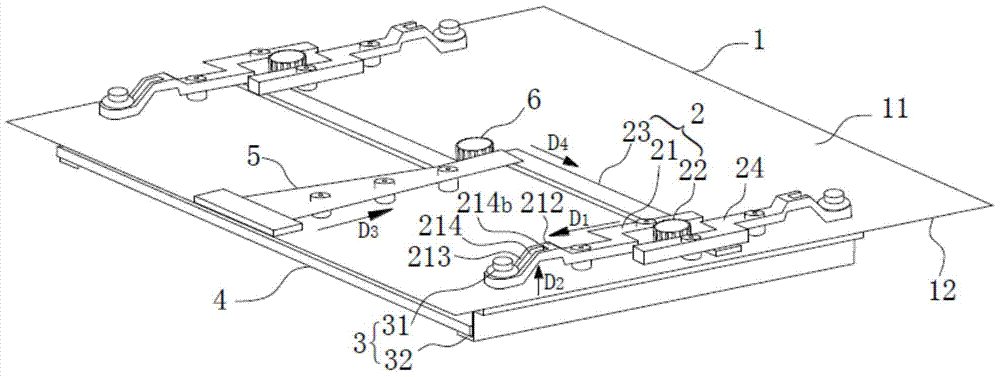

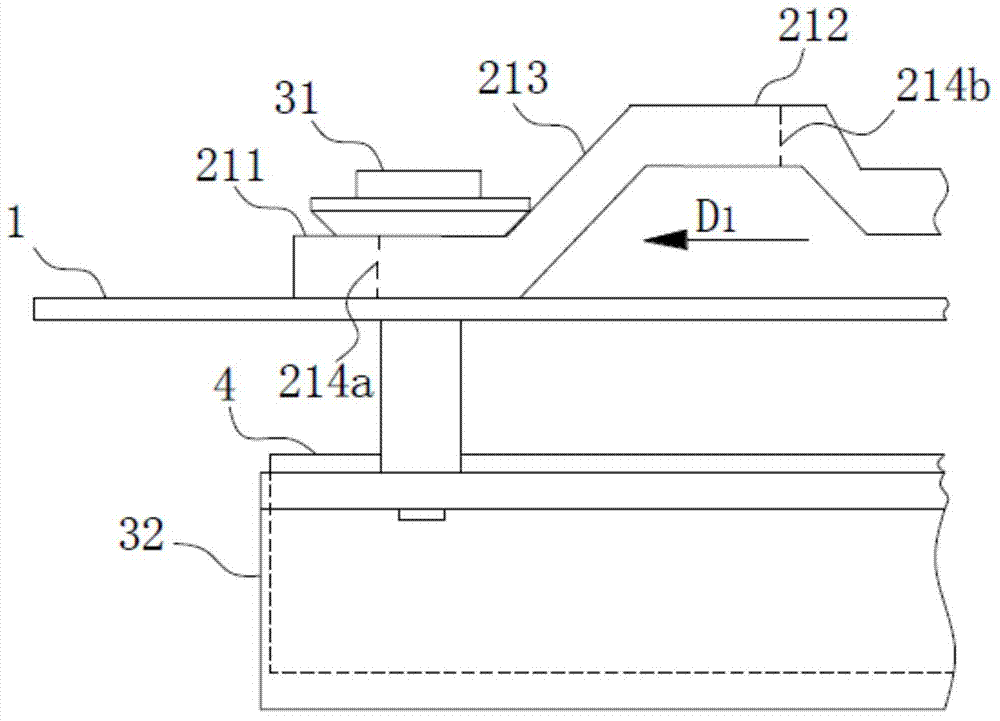

[0036] refer to Figure 1 to Figure 3-3 As shown, a schematic structural view of the first embodiment of the printing device of the present invention is disclosed. The printing device includes a substrate 1 , a driving structure 2 , a slide rail structure 3 , a forming plate 4 , a braking part 5 and a first transmission device 6 .

[0037] The substrate 1 has a first surface 11 and a second surface 12 , the first surface 11 is parallel to the second surface 12 , and the first surface 11 is opposite to the second surface 12 .

[0038] The drive structure 2 has a transmission rod 23, a second transmission device 22, a drive rod 21, a first receiving surface 211, a second receiving surface 212, and a first inclined surface 213. The first receiving surface 211 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com