A clamping method and clamping device for workpiece clamping

A clamping device and workpiece clamping technology, which is applied in the direction of clamping devices, positioning devices, metal processing machinery parts, etc., can solve the problems of reduced workpiece processing accuracy, time and effort, and difficulty, so as to improve production efficiency, Guaranteed processing accuracy and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

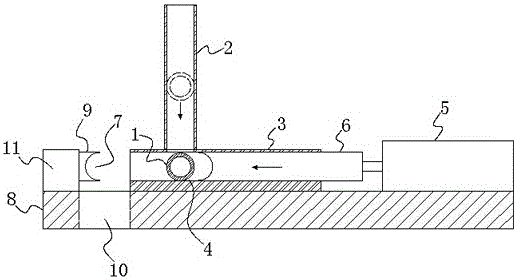

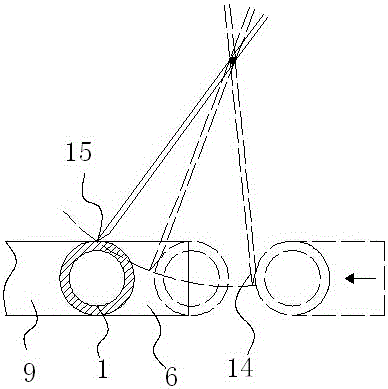

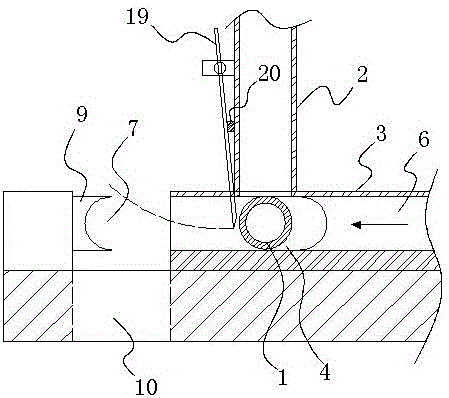

[0040] Example: such as Figure 10 As shown, a clamping method for workpiece clamping, which is to make the workpiece 1 enter the feeding position 4, and then push the workpiece 1 to move towards the fixed half-mold 9 at the processing position through the movable half-mold 6 Finally, through the cooperation of the movable half-mold 6 and the fixed half-mold 9, the movable half-mold 6 and the fixed half-mold 9 are respectively clamped on both sides of the workpiece 1 so as to clamp and fix the workpiece 1 for processing, After the workpiece 1 enters the feeding position, an auxiliary clamping process is added in the process of clamping and fixing the workpiece 1 through the cooperation of the movable half-mold 6 and the fixed half-mold 9, that is, setting a The auxiliary clamping mechanism of the auxiliary clamping part 14, when the movable half mold 6 pushes the workpiece 1 to move towards the fixed half mold 9 at the processing position, the workpiece 1 will be in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com