Assembly tooling and forming method of deep-sea spherical shell pressure-resistant structure

A technology for assembling tooling and pressure-resistant structures, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of difficult construction and assembly, and achieve the effects of small welding workload, stable spherical shell structure, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

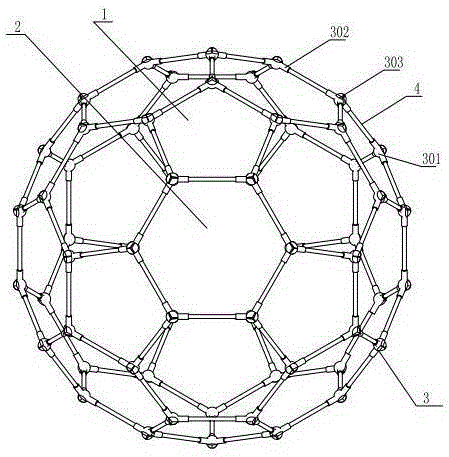

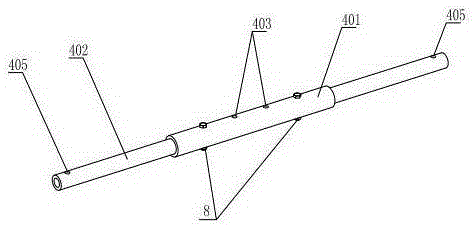

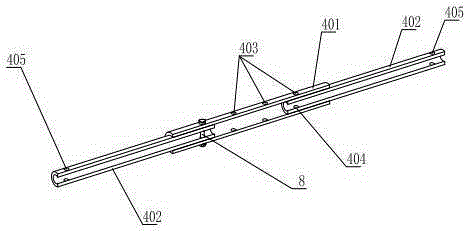

[0032] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the assembly tooling of the deep-sea pressure-resistant structure of the present invention is a hollow spherical frame structure, and the hollow spherical frame structure is formed by splicing twelve regular pentagonal frames 1 and twenty regular hexagonal frames 2 with equal sides. , each regular hexagonal frame 2 is connected with three regular pentagonal frames 1 and three regular hexagonal frames 2 arranged at intervals; twelve regular pentagonal frames 1 and twenty regular hexagonal frames 2 is formed by splicing sixty joints 3 and ninety pipe fittings 4 . The joint 3 includes a spherical body 301 and three taps 302 arranged on the periphery of the spherical body 301. Among the three taps 302, the angles between two adjacent taps 302 are 120°, 120° and 108° respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com