Single-contact spot-welding gun and application thereof

A contact point, single-sided technology, applied in the direction of welding equipment, resistance welding equipment, resistance electrode holders, etc., can solve the problems of inner and outer plates in series, appearance coverings that cannot apply appearance quality requirements, size fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

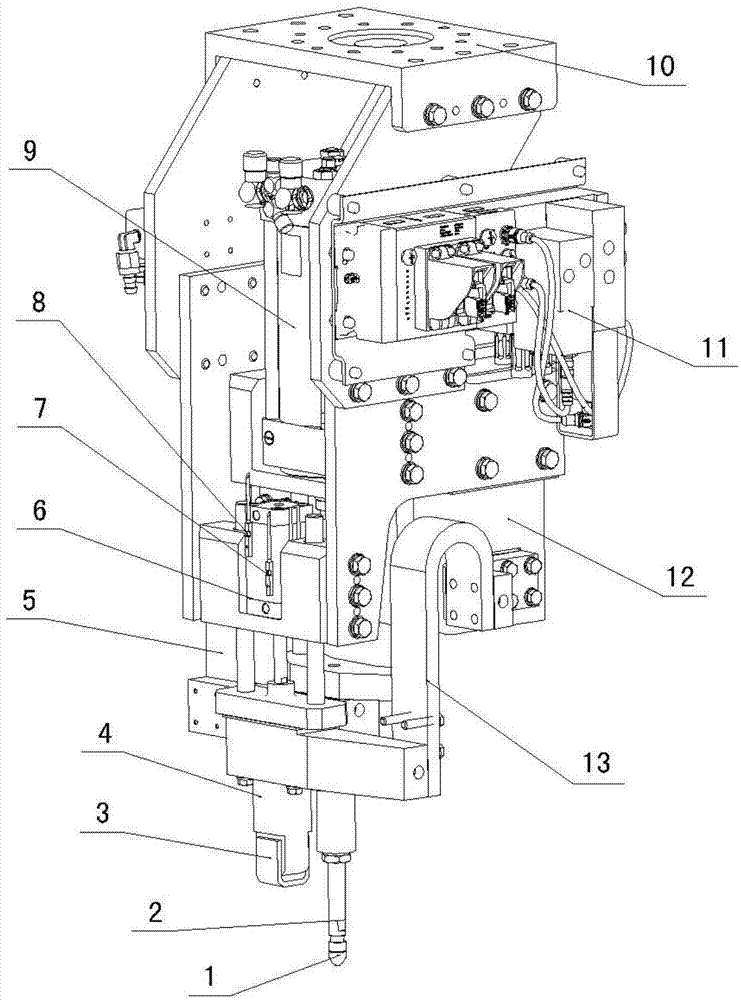

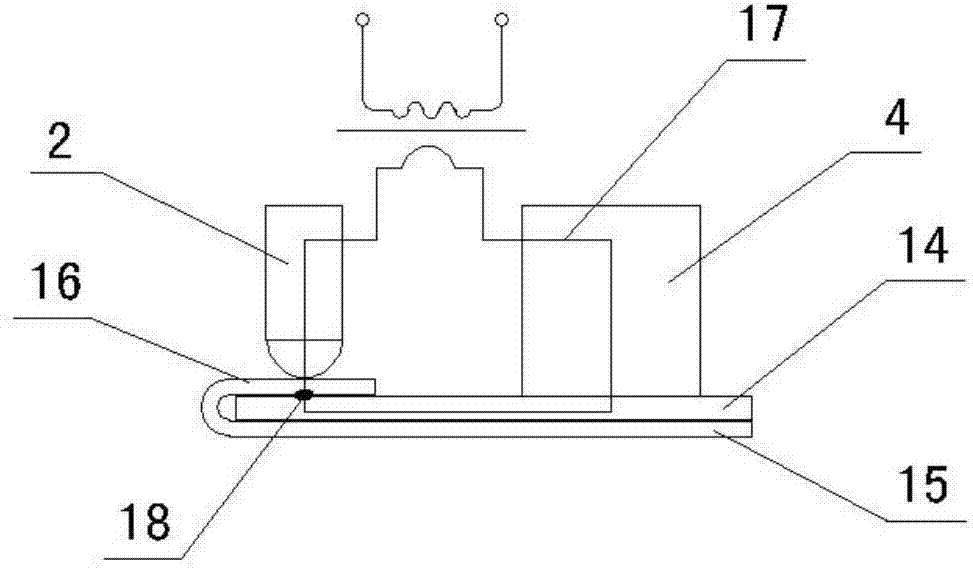

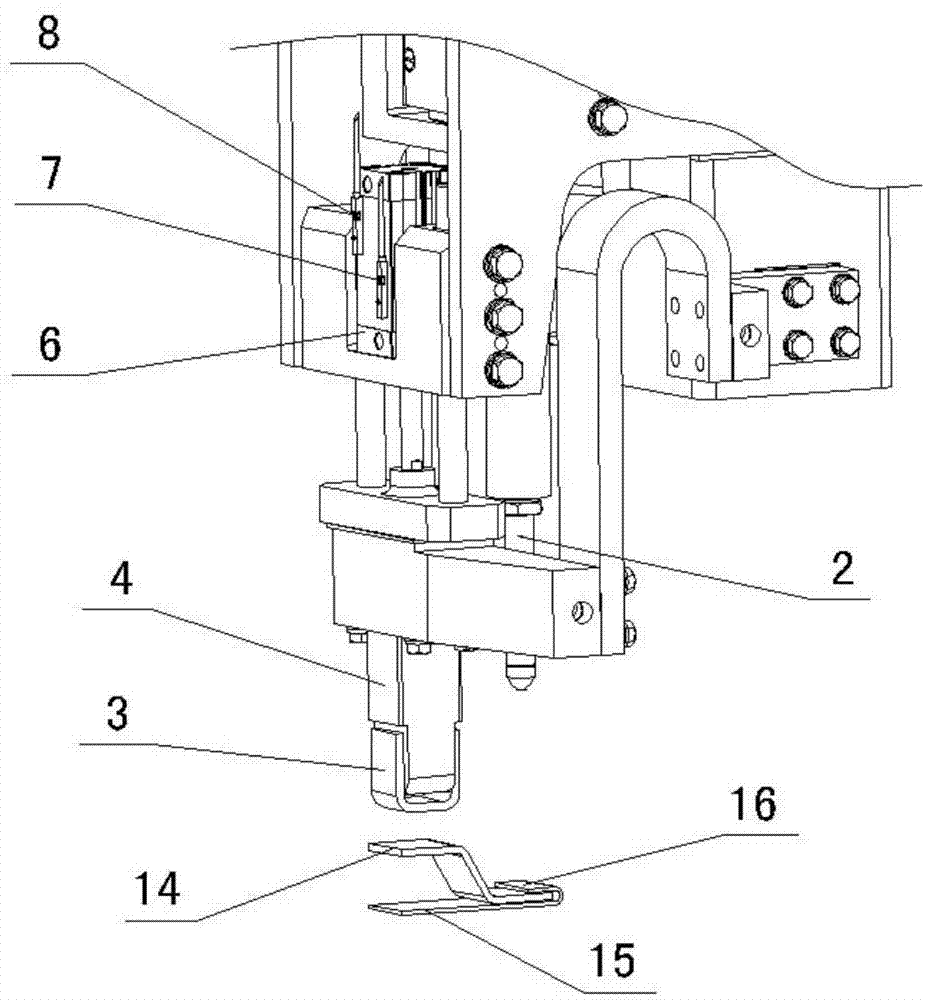

[0017] see figure 1 and figure 2 , the structural form of the single-sided contact spot welding torch in this embodiment is: the main electrode 2 and the secondary electrode 4 are arranged in parallel through the torch frame at the bottom of the mounting base 10, and the electrode cap 1 is installed at the front end of the main electrode 2, and the The main electrode 2 is driven by the air servo cylinder 9 and can move along the axis; a flexible copper strip 3 is installed on the front end of the secondary electrode 4, and the secondary electrode 4 is driven by the auxiliary cylinder 6 and can move along the axis; The primary electrode copper strip 13 is connected between the primary electrode 2 and the welding transformer 12 , and the secondary electrode copper strip 5 is connected between the secondary electrode 4 and the welding transformer 12 .

[0018] In specific implementation, a working position sensing switch 7 and an open position sensing switch 8 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com