Method, equipment and system for manufacturing metal product and control method of equipment

A metal product and metal technology, which is applied to equipment for supplying molten metal, equipment for feeding molten metal into casting molds, and metal processing equipment, etc., can solve the problems of high price, low filling rate, slow printing speed, etc. The effect of unaffected, high production precision and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

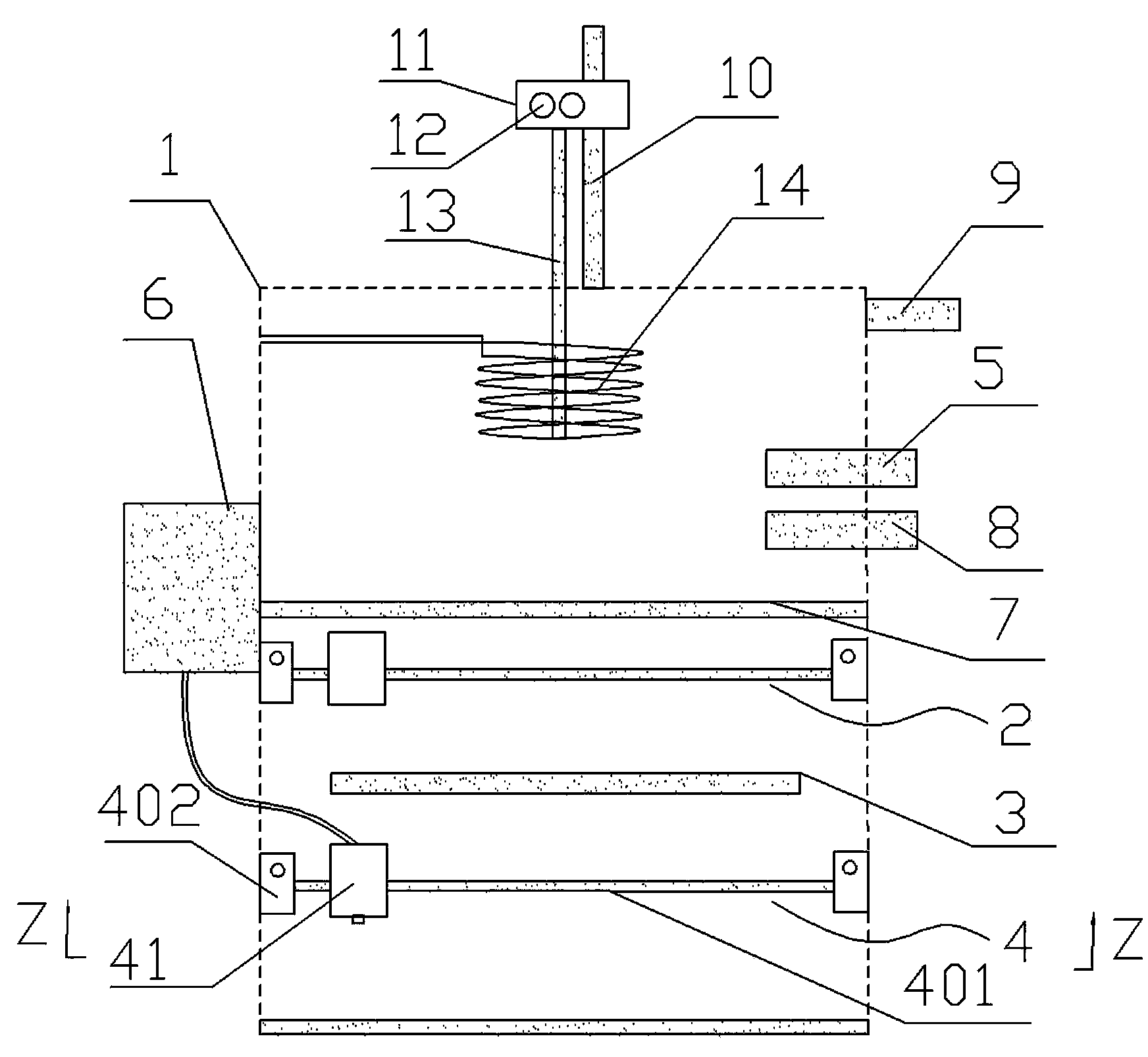

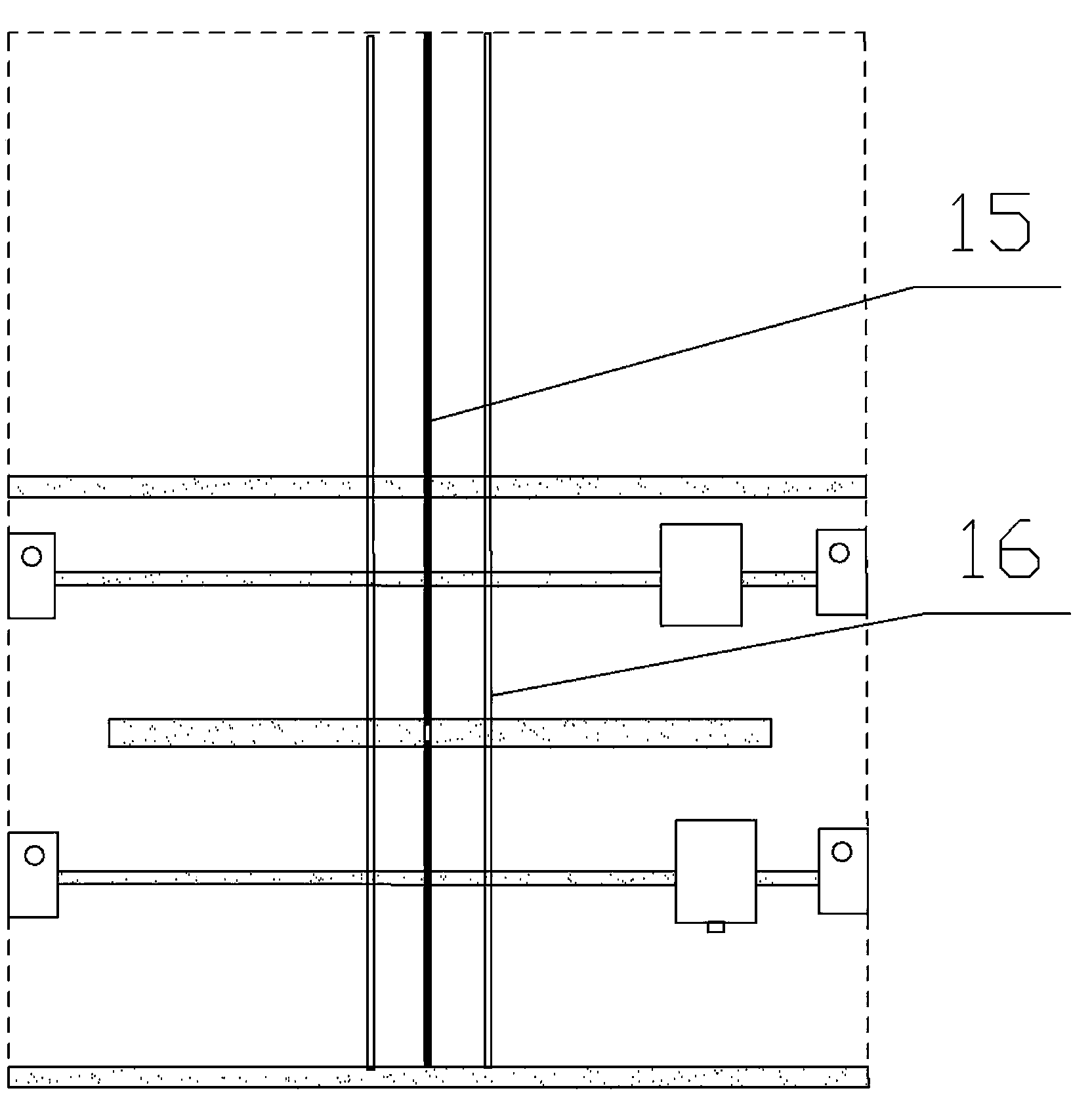

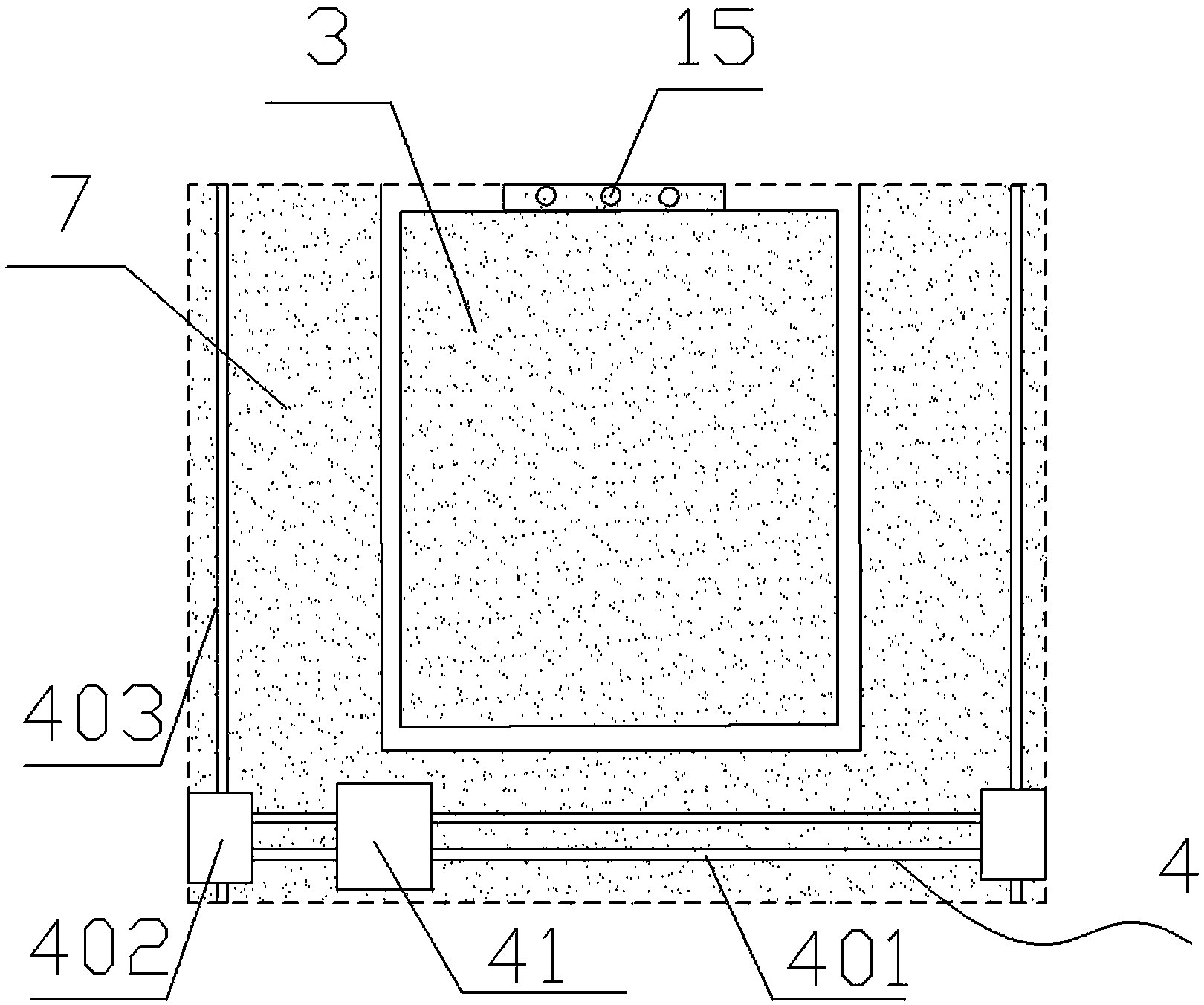

[0039] Such as figure 1 As shown, the equipment for manufacturing metal products of the present invention includes a frame 1 and a 3D printing device for printing a fusible material model. The cavity between the mold and the male mold of the fusible material; the forming melting device is used to dry the high temperature resistant material slurry and melt the fusible material at the same time; the metal melting device is used to melt metal; the molten metal injection device is used to injecting the melted molten metal into the high-temperature-resistant material female mold; moving the positioning mechanism to position the outlet of the high-temperature-resistant material slurry or the molten metal respectively with the opening of the fusible material female mold or the high-temperature-resistant material female mold, In order to accurately inject the corresponding position; and a liquid quantity detector, used to detect the quantity of injected high temperature resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com