Chip film fixed resistor with resistance of 10-1Momega

A fixed resistance and range technology, applied in the field of electronic devices, can solve the problems of large resistance deviation, circuit damage, high failure rate of resistors, etc., and achieve the effect of large resistance range, good moisture resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

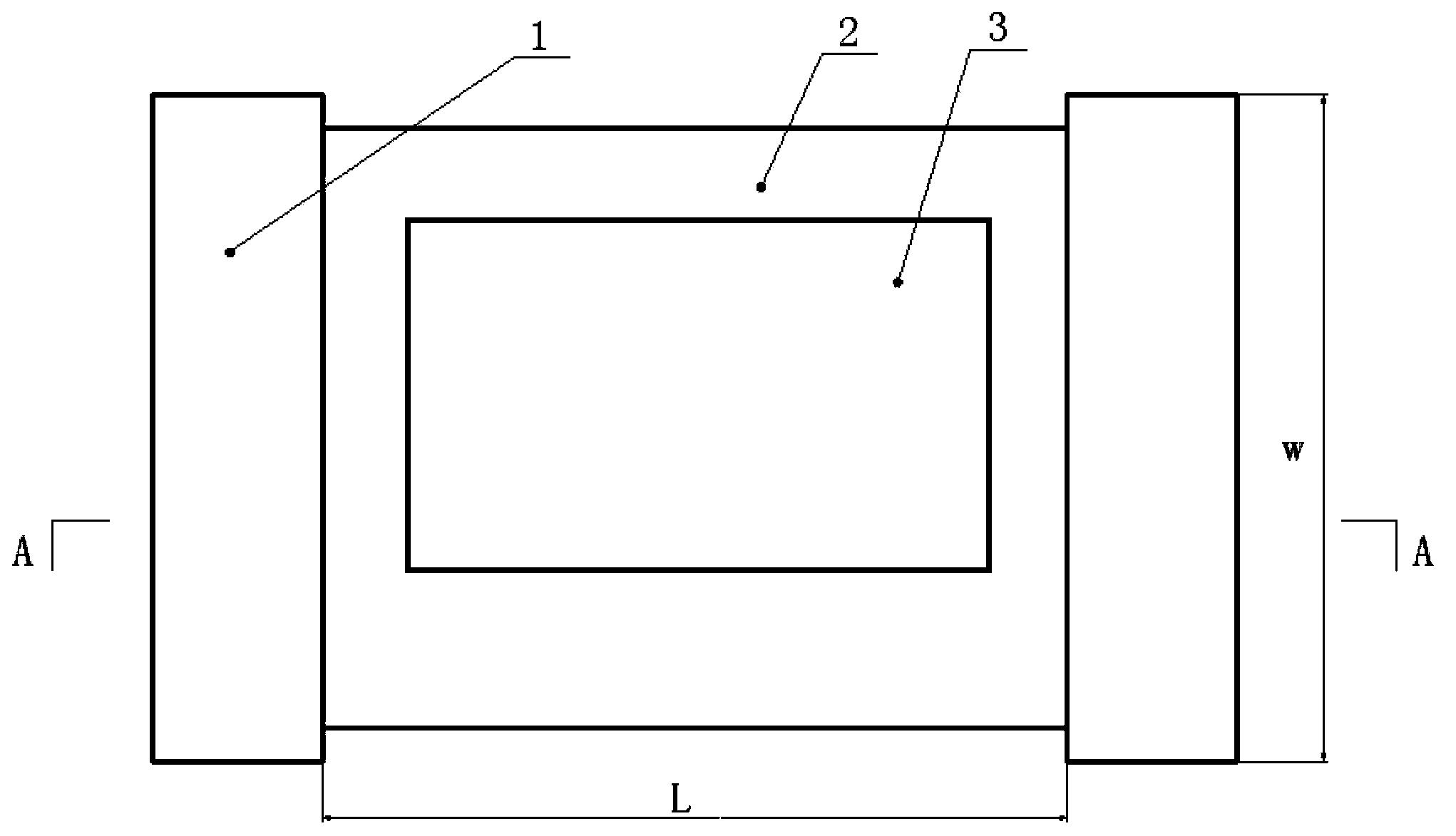

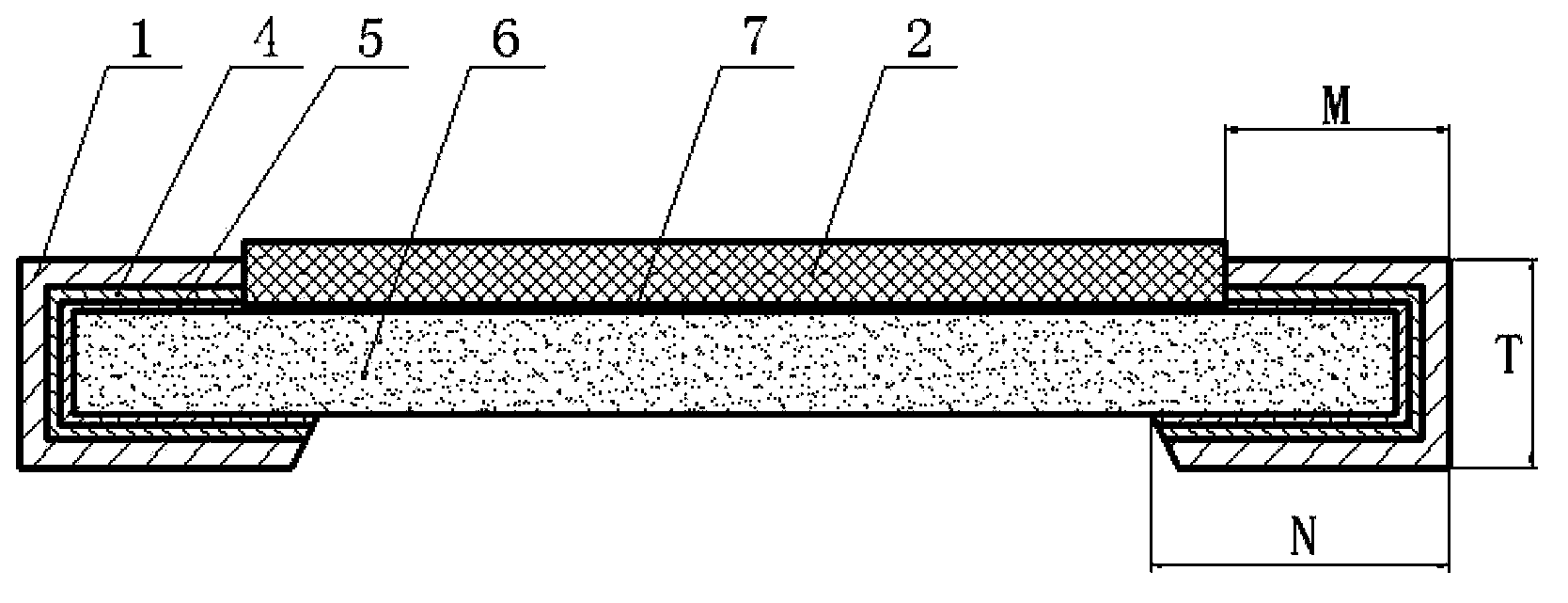

[0016] A chip-type film fixed resistor with a resistance value ranging from 10 to 1 MΩ, including a substrate 6, a metal resistance layer 7, an inner electrode layer 5, an outer electrode layer 1, and a protective layer 2, and a metal resistance layer is installed in the middle of the upper surface of the substrate, The metal resistance layer is a metal thin film, and the inner electrode layer is mirror-symmetrically coated on the substrate on both sides of the metal resistance layer. Both inner electrode layers are connected with the metal resistor body, and each inner electrode layer is covered with an outer electrode layer. , a nickel alloy layer 4 is installed between each inner electrode layer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com