Dual-frequency communication based intelligent management method and system of weight measurement

A management method and communication pair technology, which is applied in the field of intelligent management of weight measurement based on dual-frequency communication, can solve the problems of inability to meet the requirements of the grain depot management system, difficulty in communication, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

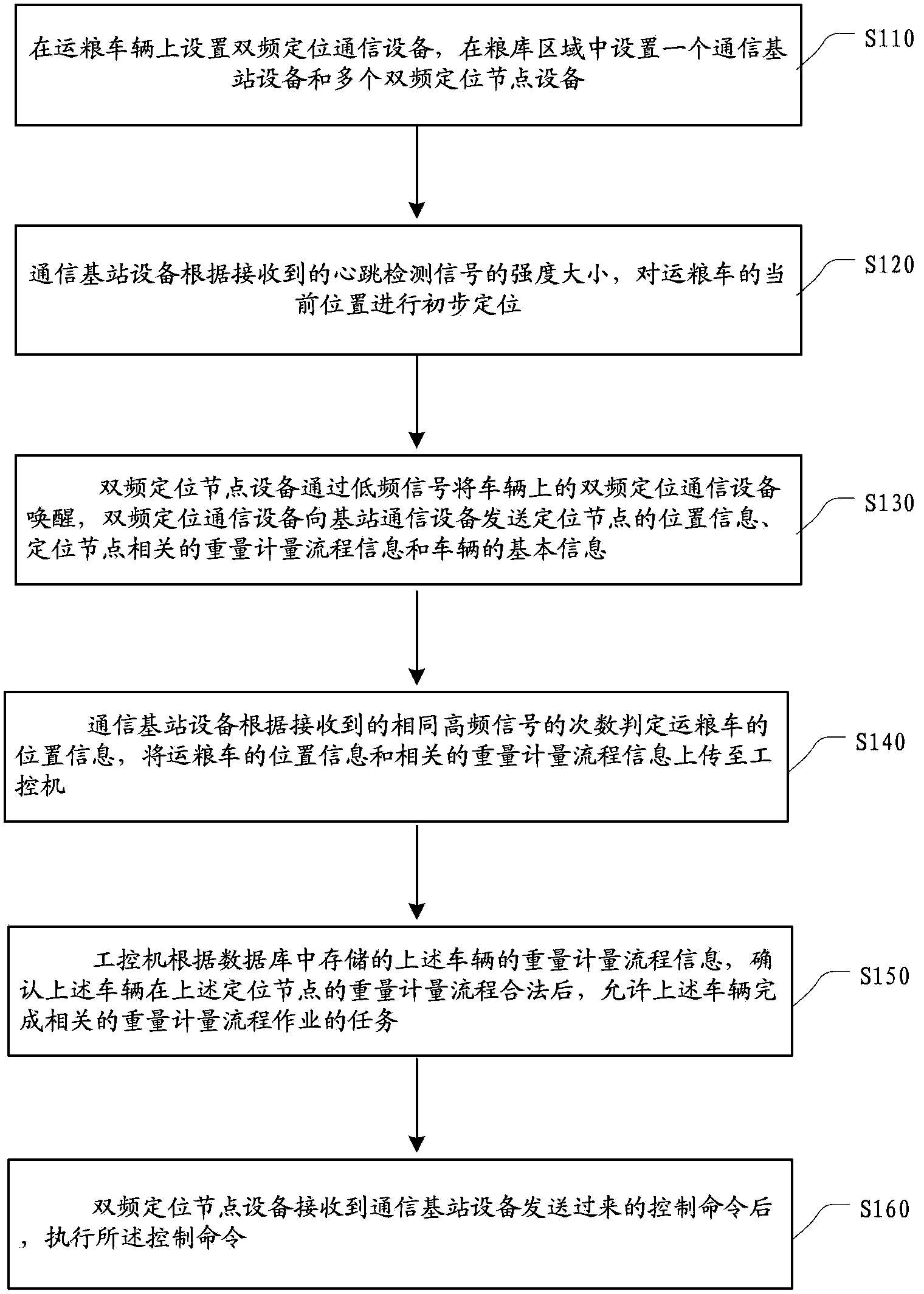

[0066] In the embodiment of the present invention, dual-frequency positioning communication equipment is installed on the vehicle, and communication base station equipment and multiple dual-frequency positioning node equipment are installed in the weight measurement area. The communication base station equipment, dual-frequency positioning node equipment, and dual-frequency positioning communication equipment pass through Wireless communication is performed in the high-frequency band, wireless communication is performed between the dual-frequency positioning node device and the dual-frequency positioning communication device through the low-frequency band, and wired communication or wireless communication is performed between the communication base station device and the industrial computer for comprehensive management of weight measurement.

[0067] The embodiment of the present invention can be applied to a variety of weight measurement processes. The following uses the weighi...

Embodiment 2

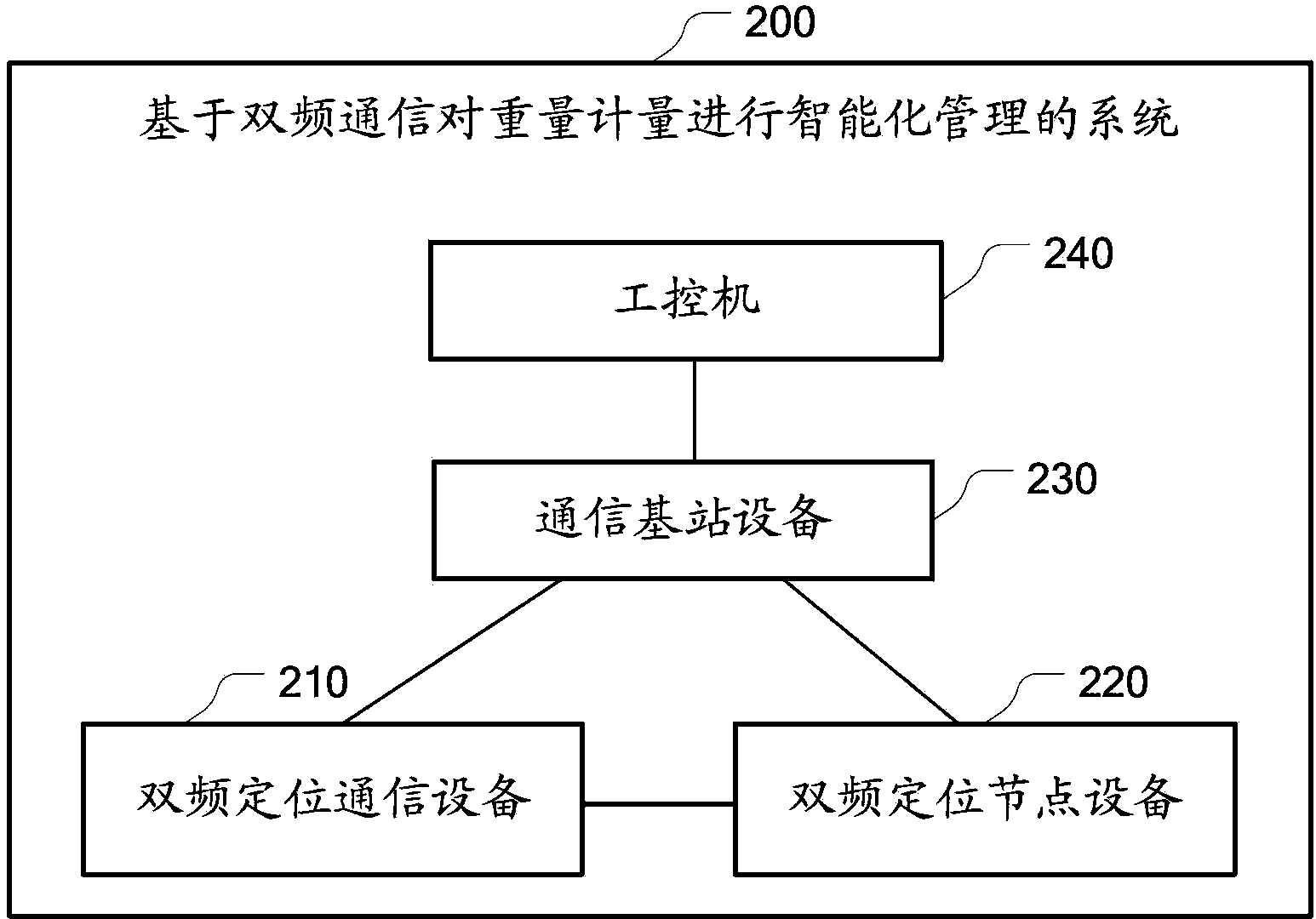

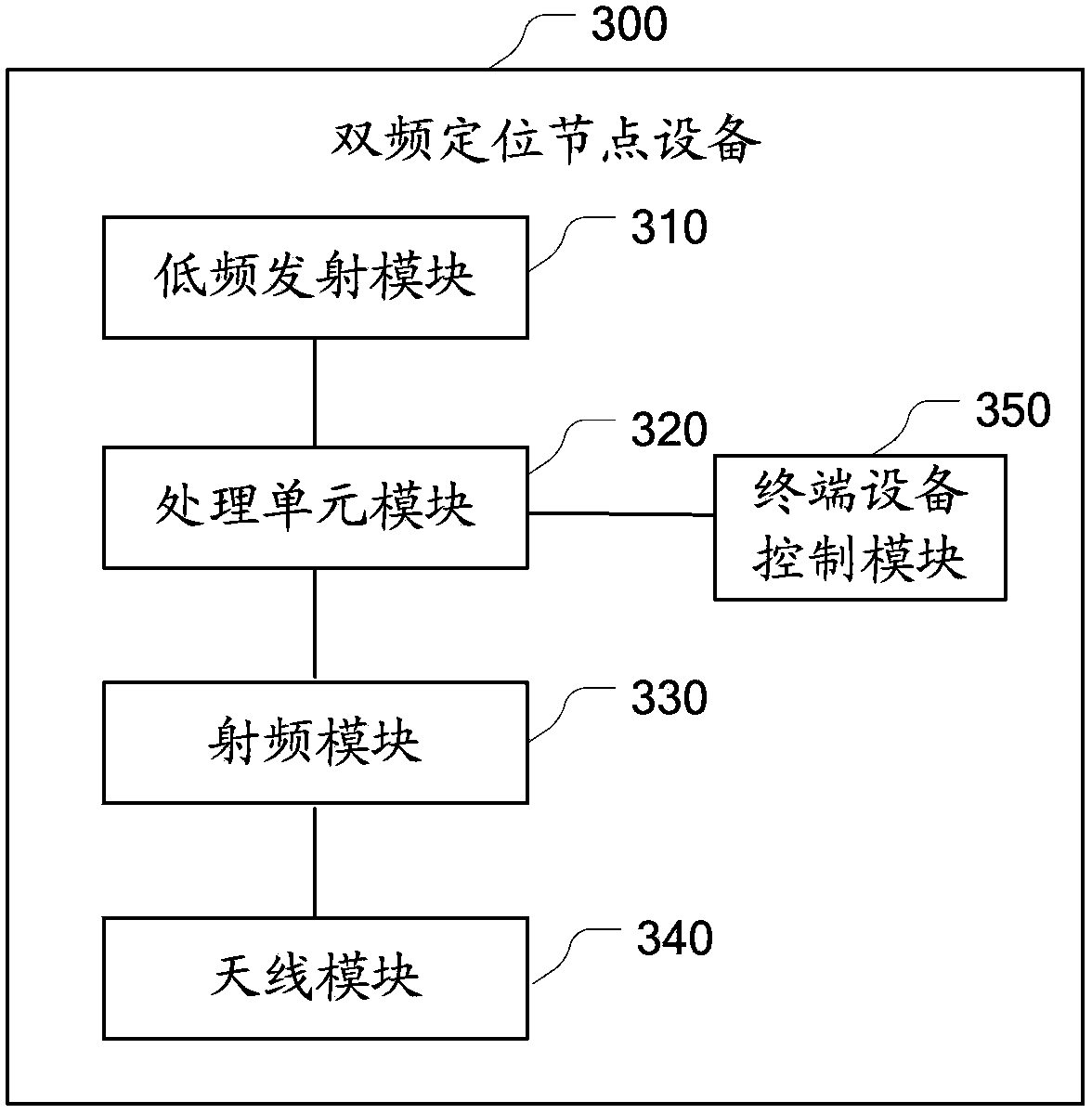

[0097] This embodiment provides a system for intelligently managing weight measurement based on dual-frequency communication. The specific structure of the system is as follows: figure 2 As shown, it includes the following modules: dual-frequency positioning communication equipment, dual-frequency positioning node equipment, communication base station equipment and industrial computer,

[0098] The dual-frequency positioning node device is configured to be installed on a positioning node in the weight measurement area, and regularly sends out low-frequency signals, and the low-frequency signal includes the position information of the positioning node and the weight measurement process related to the positioning node information;

[0099] The dual-frequency positioning communication device is configured to be installed on the vehicle, and when the vehicle arrives at the positioning node area in the weight measurement area, it receives the low-frequency signal sent by the dual-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com