Air exhausting device and method of discharged aluminum

A technology of exhaust device and exhaust port, which is applied in the field of aluminum ladle exhaust device, can solve the problems of high furnace temperature of electrolytic cell, increase of covering material, blockage of flue, etc., so as to reduce fugitive emissions and increase smoke exhaust. The effect of high volume and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

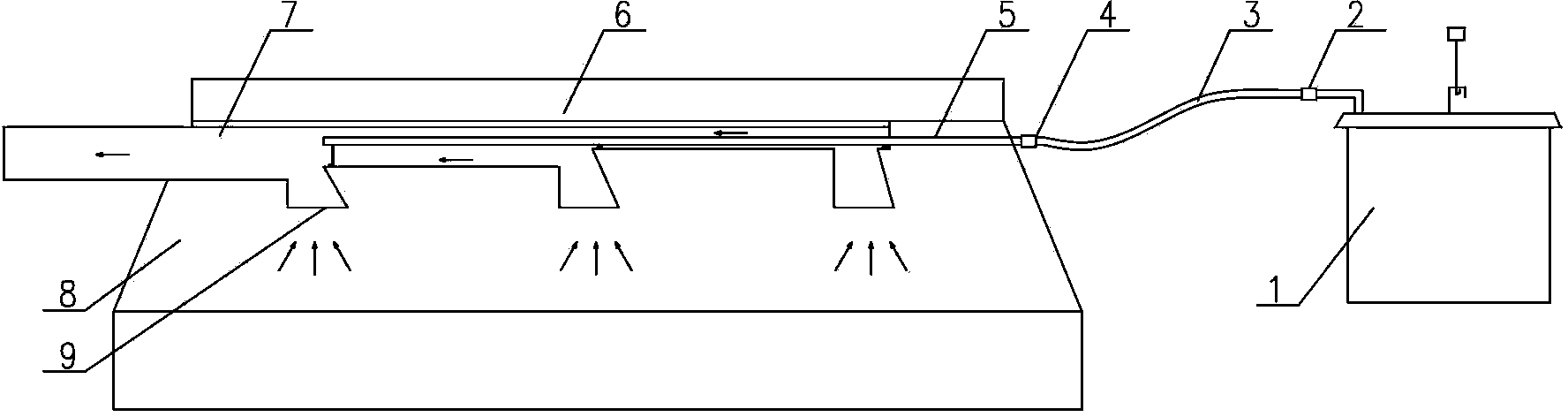

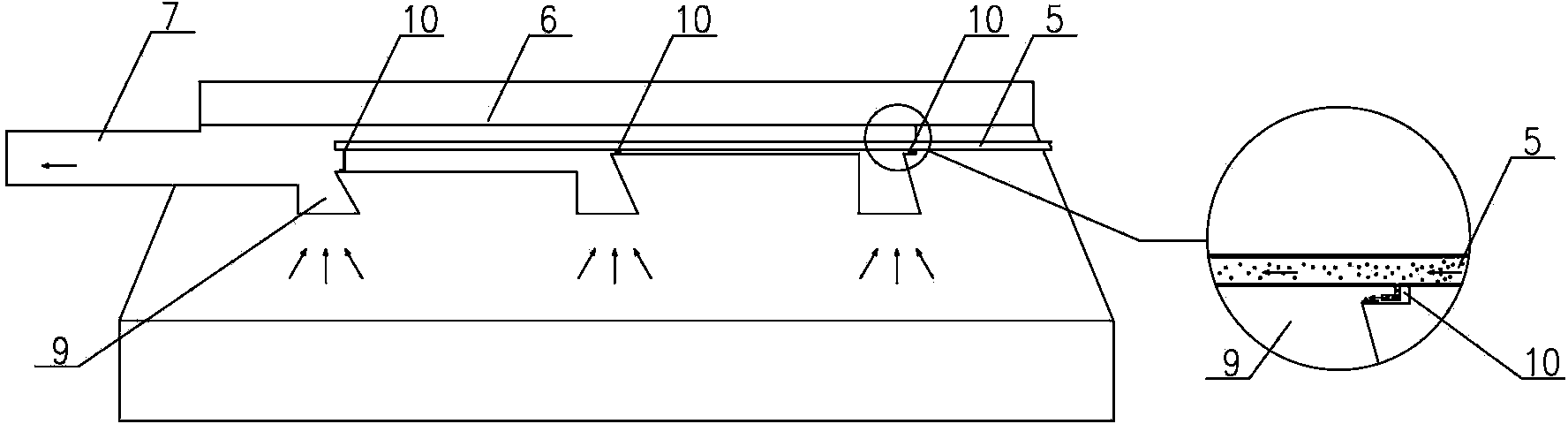

[0026] like figure 1 As shown in the figure, the aluminum discharge device has the following structure: the ladle 1, the ladle exhaust port 2 is connected with the compressed air pipe 5 through the air hose 3, and the compressed air pipe 5 is provided with the exhaust pipe 7 on the upper part of the electrolytic cell. , the bottom of the exhaust pipe 7 is provided with an electrolytic cell gas collecting cover 9, and the compressed air pipe 5 is provided with a nozzle 10.

[0027] The air outlet 2 of the bag is arranged on the top of the bag 1, and an air hose 3 is arranged between the air outlet 2 of the bag and the compressed air pipe 5.

[0028] The number of ladle exhaust ports 2 is 1-5.

[0029] The compressed air pipe 5 is connected through the quick joint 4 of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com