Processing apparatus equipped with catalyst-supporting honeycomb structure, and method for manufacturing same

A technology of a honeycomb structure and a treatment device, which is applied in the directions of catalyst carrier, catalyst activation/preparation, gas treatment, etc., can solve the problems of reducing the contact area of the treated gas, increasing the pressure loss, blocking the mesh of the honeycomb structure, etc. Effects of simple regeneration treatment, prevention of contact area reduction, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

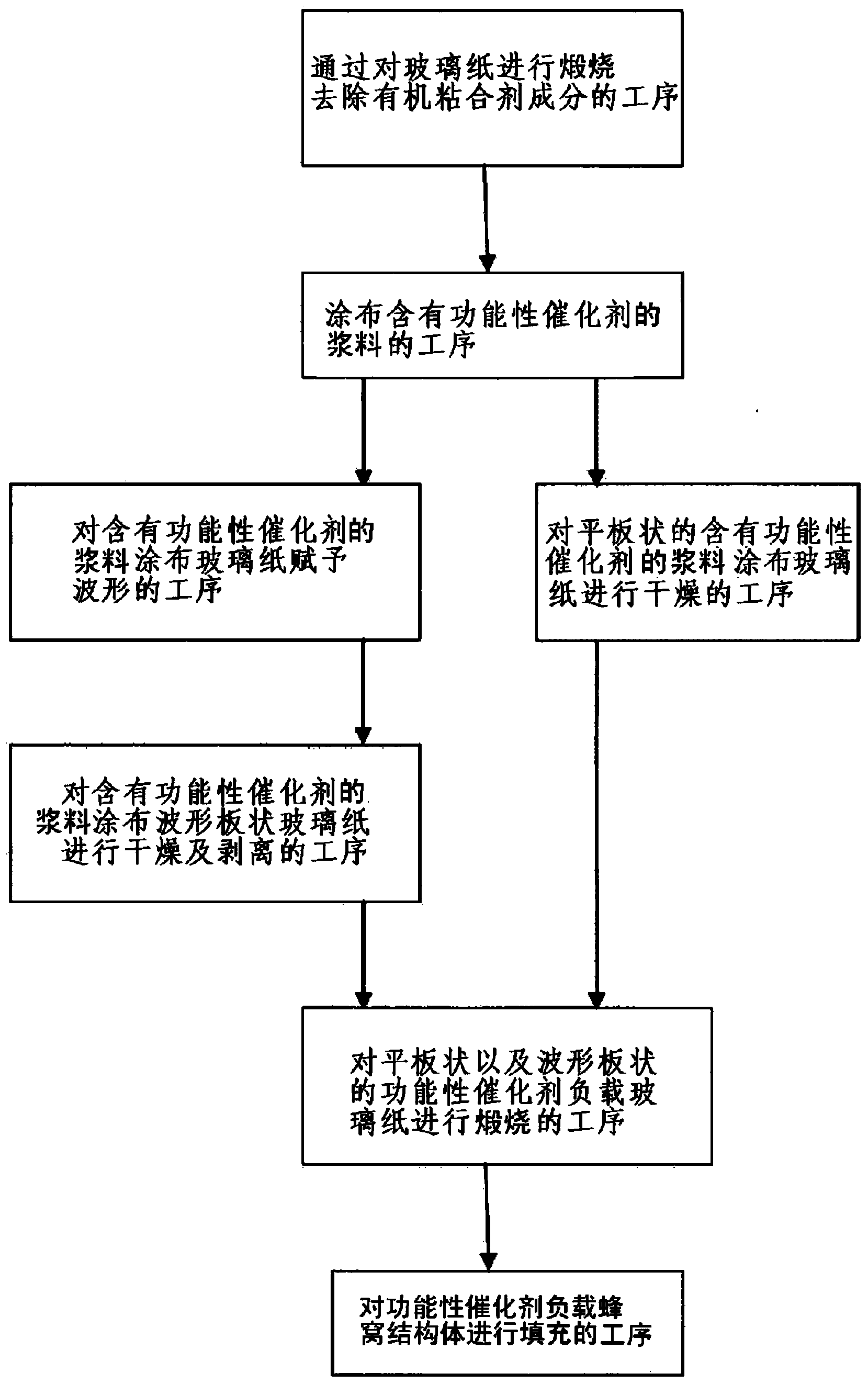

[0095] By the method of the present invention, a denitration catalyst-supporting honeycomb type treatment device is manufactured as follows.

[0096] First, in the method of the present invention, in the process of calcining commercially available cellophane and burning and removing the organic binder component contained in the cellophane, as the commercially available cellophane, organic binder made of acrylic resin is used. Cellophane made of agent. The cellophane is rolled into a roll, and the cellophane with a length of 950 mm is cut from the roll.

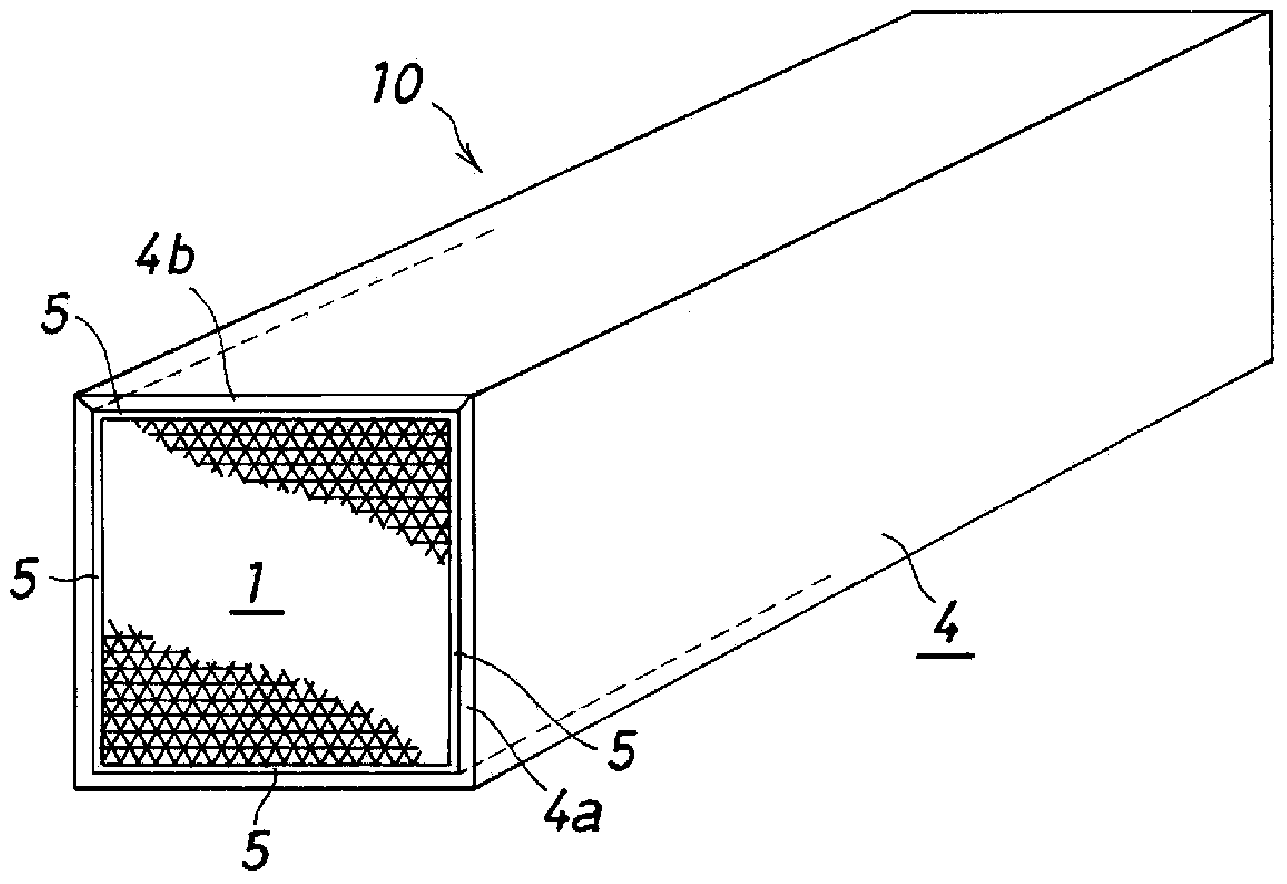

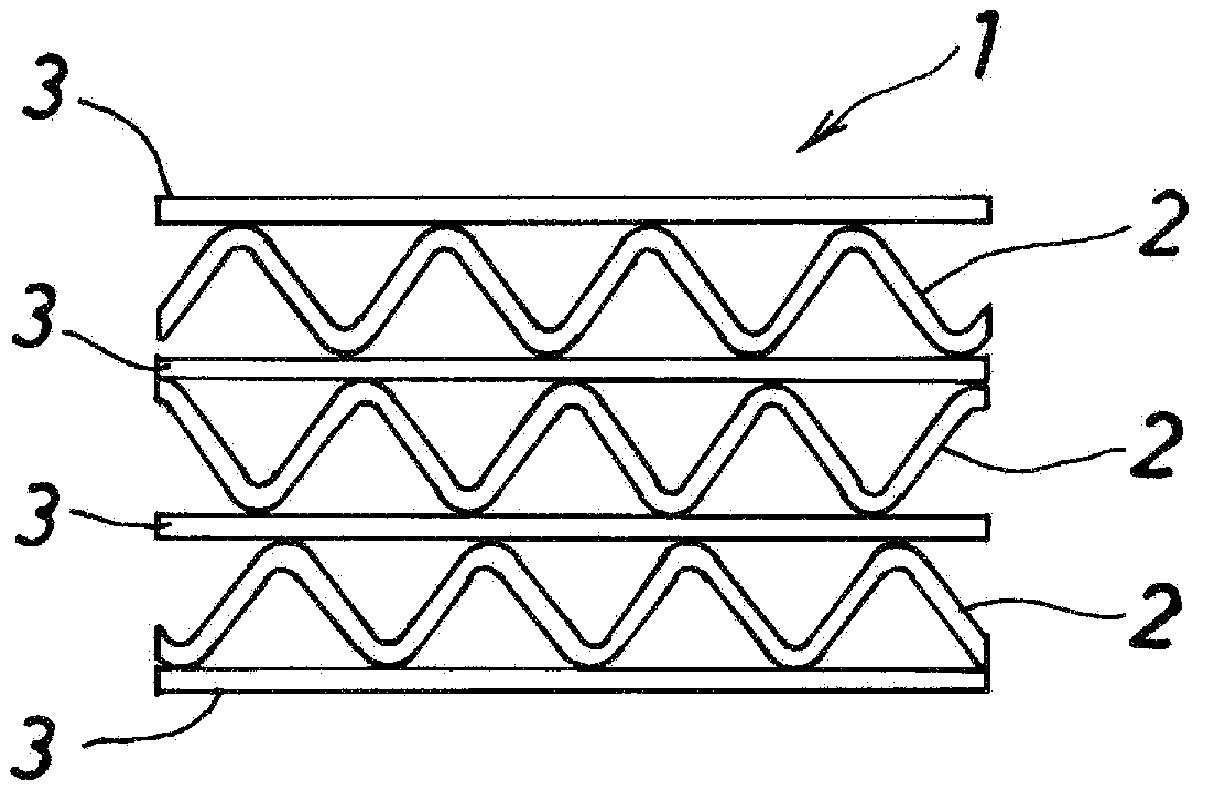

[0097] On the other hand, in order to obtain a flat denitration catalyst-supported cellophane (3) that is not shaped into a corrugated plate, commercially available cellophane is also cut from a roll, but in order to be finally combined with the glass paper that is filled in the angular cylindrical case (4) The corrugated plate-shaped denitration catalyst-supported cellophane (2) is of the same size when viewed from above, an...

Embodiment 2

[0115] Similar to the case of the above-mentioned Example 1, the denitration catalyst-supported honeycomb treatment device (10) was produced by the method of the present invention, but the difference from the case of the above-mentioned Example 1 was the composition of the slurry containing the denitration catalyst.

[0116] That is, 10 g of ammonium metavanadate was added per 1 kg of the slurry to a slurry in which titanium dioxide fine particles were suspended in silica sol (the solid content ratio was 45% by weight, and the ratio of silicon dioxide to titanium dioxide was 20:80). powder, and the whole was stirred for 1 hour, so that the ammonium metavanadate was adsorbed on the titanium dioxide.

[0117] Next, 28 ml of ammonium metatungstate aqueous solution (3.88 mol / L) was further added to the slurry per 1 kg of the slurry, and the whole was stirred for 1 hour.

[0118] A denitration catalyst-supporting honeycomb type treatment device ( 10 ) was produced in the same manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com