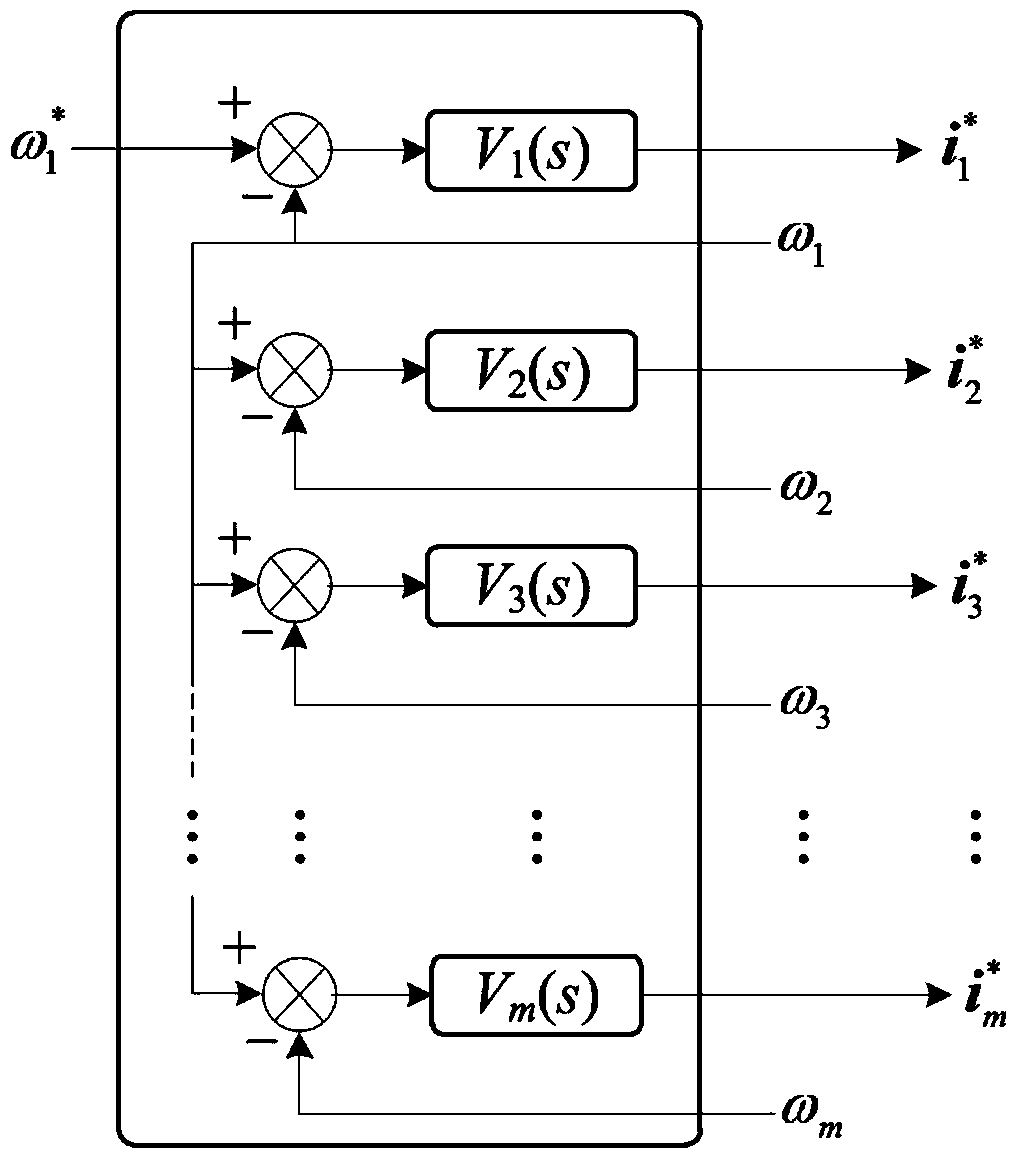

Finite control set model predictive control method for multi-motor control system

A technology of model predictive control and multi-motor control, applied in the control system, vector control system, motor generator control and other directions, can solve the problems of short calculation time, increased calculation amount, and the control period cannot be set small enough, and achieve simplification The effect of the optimization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

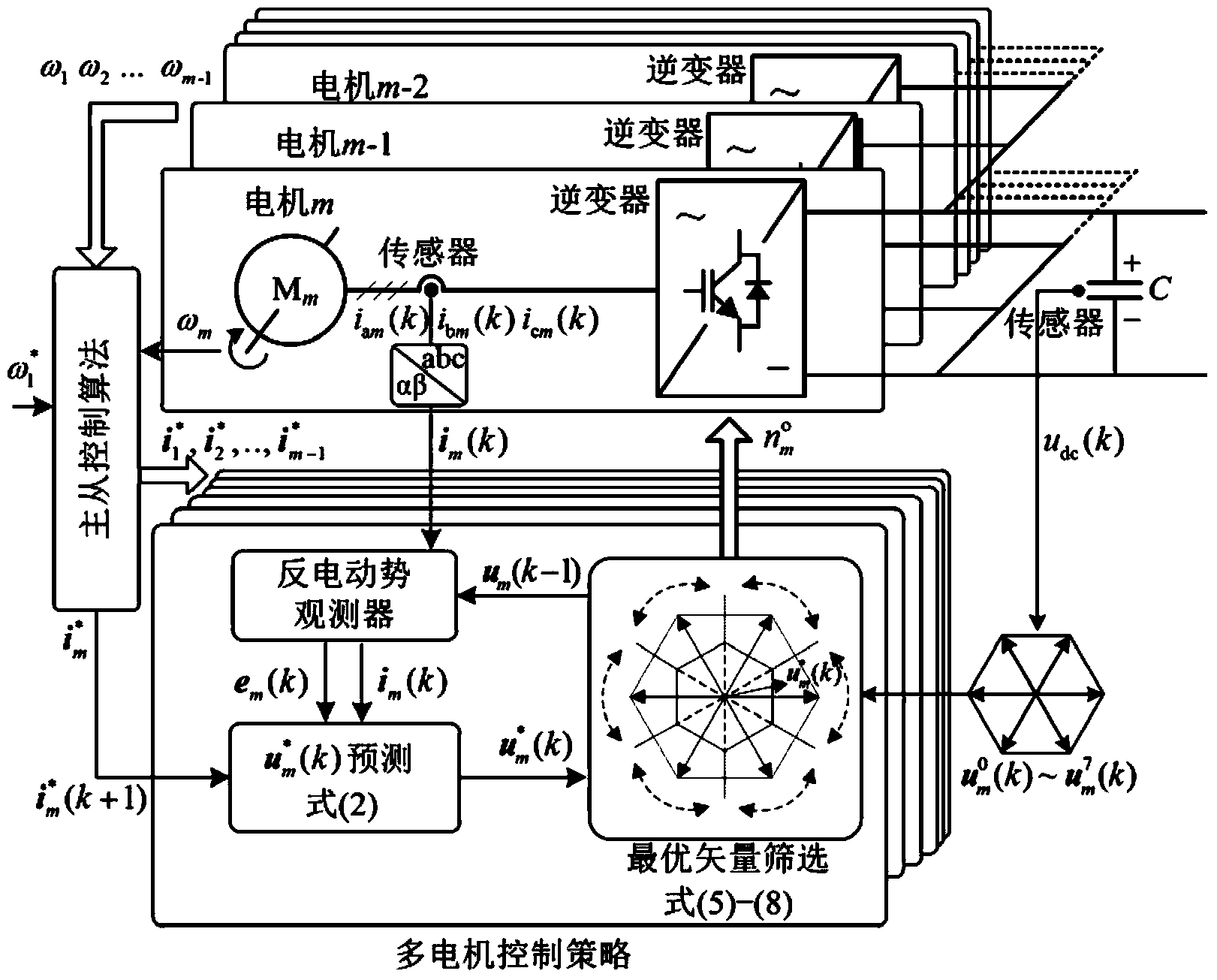

[0057] A finite state model predictive control method applied to a multi-motor control system of the present invention will be described in detail below with reference to embodiments and drawings.

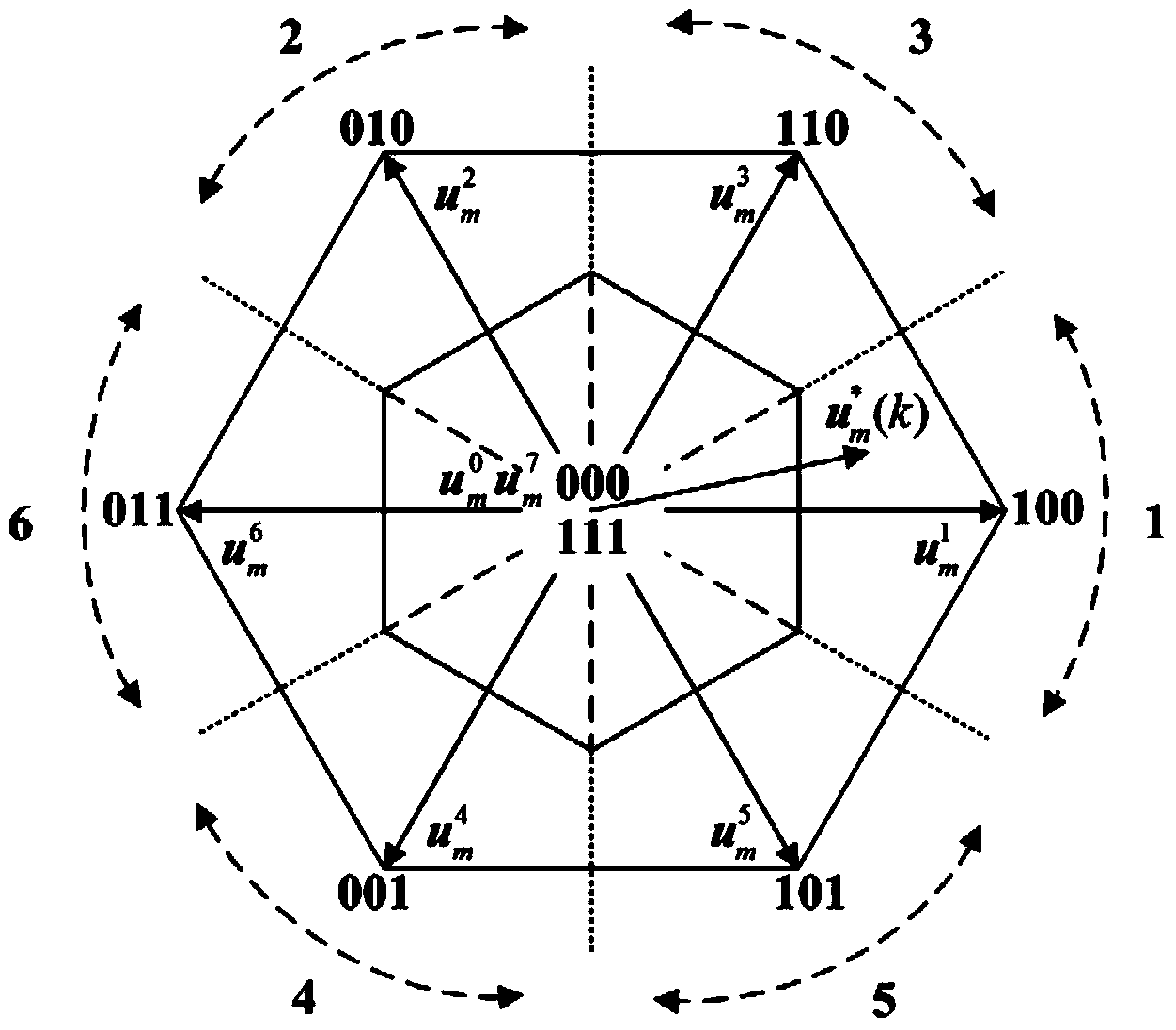

[0058] In order to reduce the calculation time of the traditional finite state model predictive control method on the multi-motor control system without weakening its control effect, a finite state model predictive control method applied to the multi-motor control system of the present invention establishes an application FCS-MPC simplified algorithm for multi-motor systems. The FCS-MPC simplified algorithm can greatly reduce the program execution time while maintaining the control effect of the traditional FCS-MPC algorithm. When FCS-MPC imposes other constraints, the simplified algorithm is still valid.

[0059] A finite state model predictive control method applied to a multi-motor control system of the present invention is applicable to a multi-motor control system composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com