Anode lead plaster of lead-acid accumulator

A technology of lead-acid battery and positive electrode paste, which is applied in the direction of battery electrodes, circuits, electrical components, etc., which can solve the problems of battery capacity drop and poor formation effect, so as to prolong the service life and overcome the softening effect of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A positive lead paste for lead-acid battery, the mass fraction of each component of the positive lead paste is: 67.9% of lead powder, 10% of red lead, 6% of sulfuric acid, 0.1% of short fiber, 15% of deionized water, and 0.5% of calcium phosphate and zinc phosphate 0.5%.

Embodiment 2-9

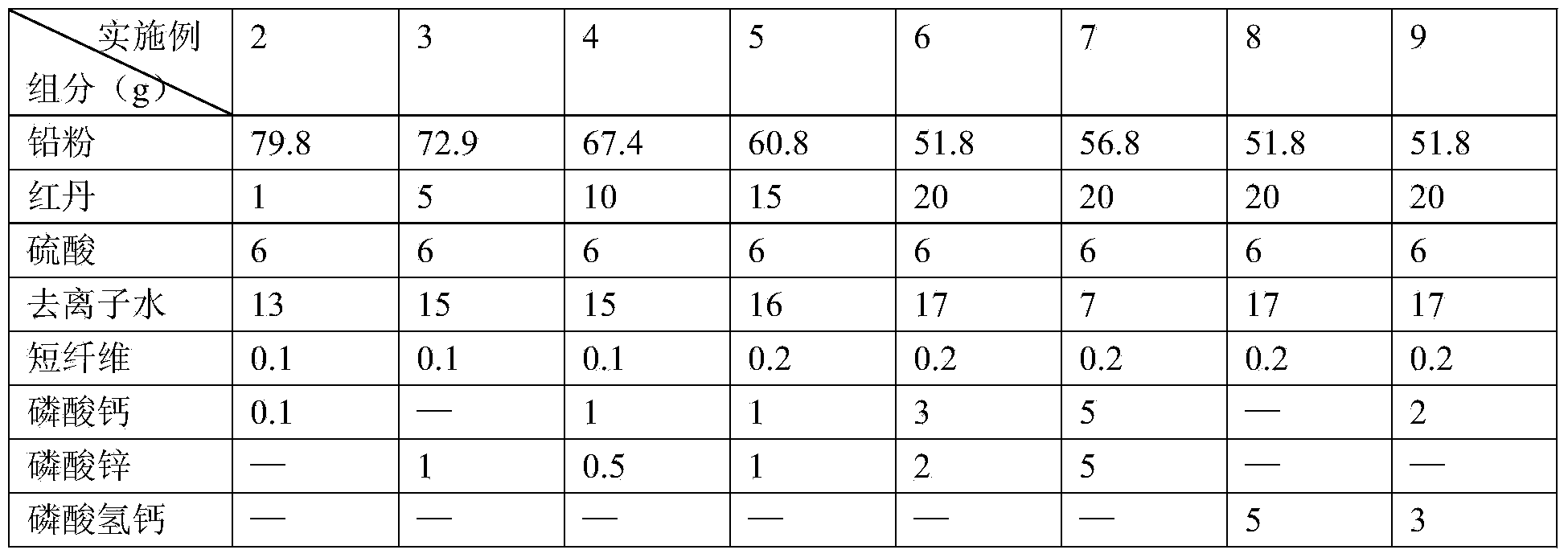

[0022] A kind of lead-acid accumulator positive electrode lead paste, the formula of this positive electrode lead paste is shown in Table 1.

[0023] Table 1

[0024]

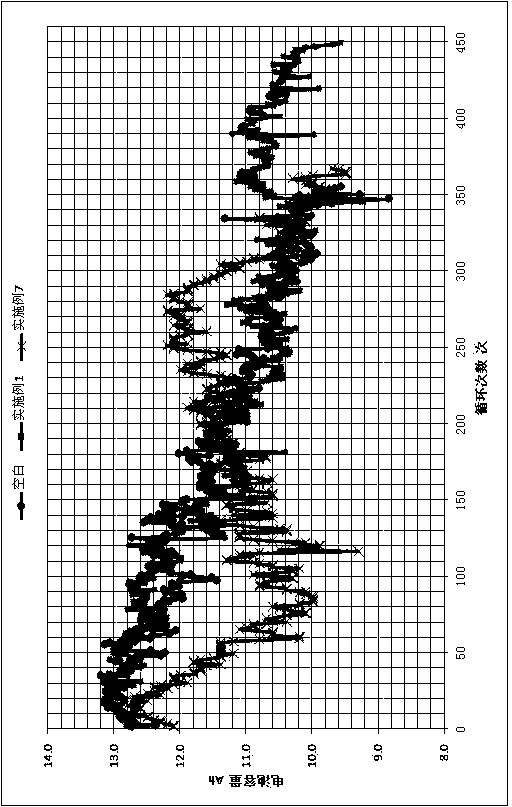

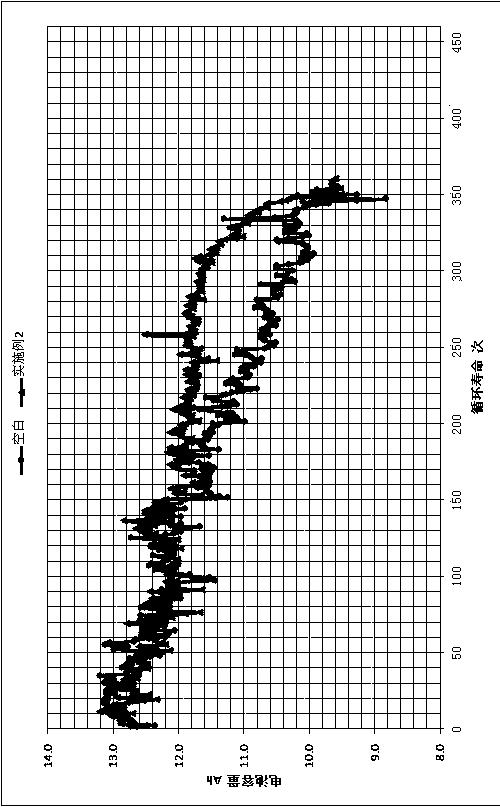

[0025] The above components and paste were made into plates, and the experiments were carried out after assembling the battery. The specific experimental conditions are shown in Table 2 (take 12V12Ah battery as an example), and the life curve is as follows figure 1 and figure 2 shown. according to figure 1 , figure 2 From the data in Table 2, it can be seen that the initial capacity, charge acceptance, and low-temperature performance of the battery are not affected, but the cycle life is significantly improved.

[0026] Table 2

[0027]

[0028] The blank formula (mass fraction): 10% red lead, 6% sulfuric acid, 0.1% short fiber, 15% deionized water, and the balance is lead powder.

[0029] The lead-acid battery cathode lead paste and the paste prepared in each embodiment were made into pole plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com