A projection objective lens for desktop stepper lithography machine

A technology of projection objective lens and lithography projection, which is applied in the field of projection objective lens, can solve the problems of increasing the difficulty of objective lens design, design limitations of high-performance projection objective lens, etc., and achieve the effect of improving lithography resolution, high numerical aperture, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

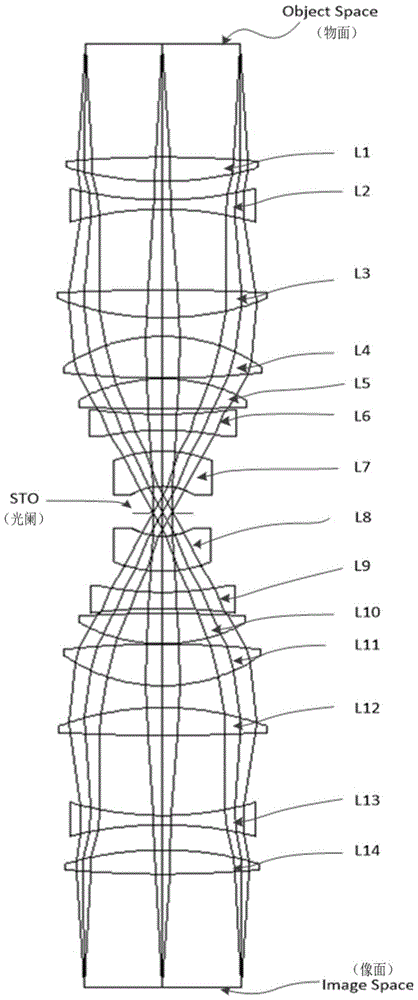

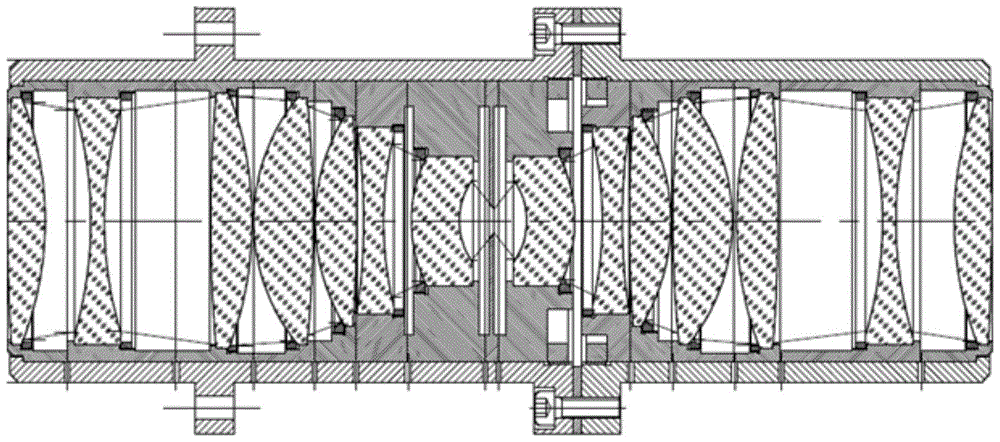

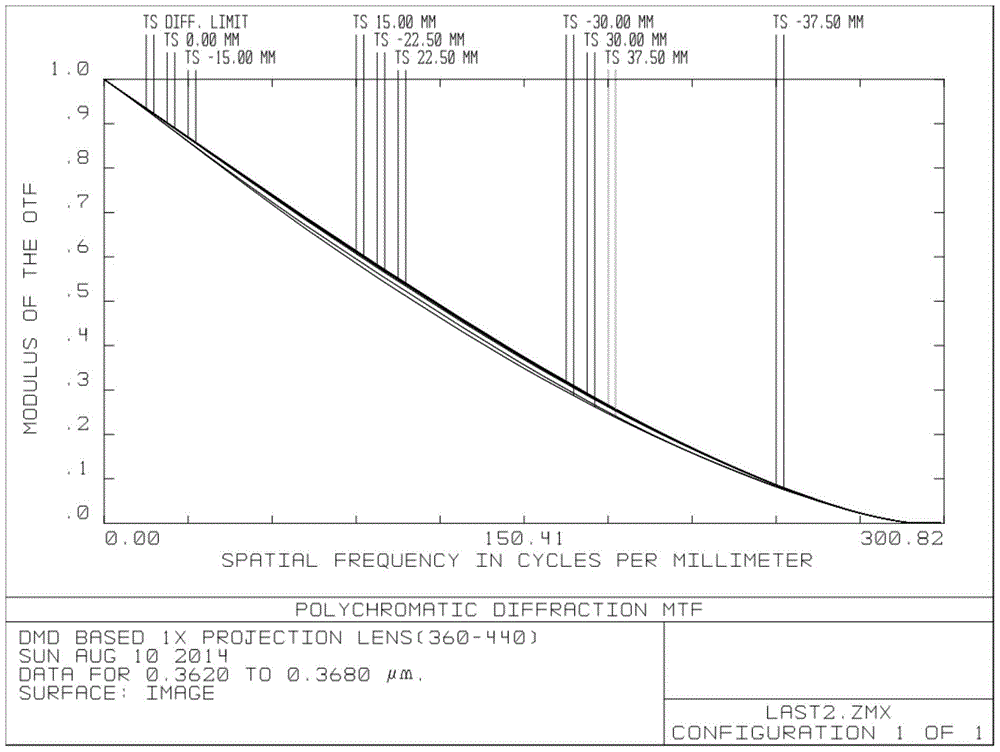

[0047] The structure of the present invention is as attached figure 1 As shown, the light emitted from the high-pressure mercury lamp is collimated and uniformed by the illumination system and then incident on the mask plate in parallel, that is, the object plane of the objective lens. Among them, the maximum size of the mask plate shall not exceed 75mm×75mm. After passing through a projection object used in the desktop STEPPER photolithography machine of the present invention, a mask image of -1 times the same proportion is formed on the surface of the silicon wafer that has been evenly glued.

[0048] as attached figure 1 As shown, the objective lens takes the incident surface of the first lens (L1) facing the object plane as the first surface, and so on along the optical axis, a total of 28 optical surfaces, 14 lenses, and the conjugate distance of the object image is L=500mm. All the lenses are mirror-symmetrical with the diaphragm as the center and have a bi-telecentric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com