Mold for concrete axial tension test piece and rod piece pre-embedding method by using the mold

An axial stretching and concrete technology, applied in the field of pre-embedding of rods and dumbbell-shaped molds, can solve the problems of difficulty in ensuring verticality, complicated positioning pre-embedding procedures, and poor axial pulling effect, and achieves easy quality assurance and verticality. Good effect and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

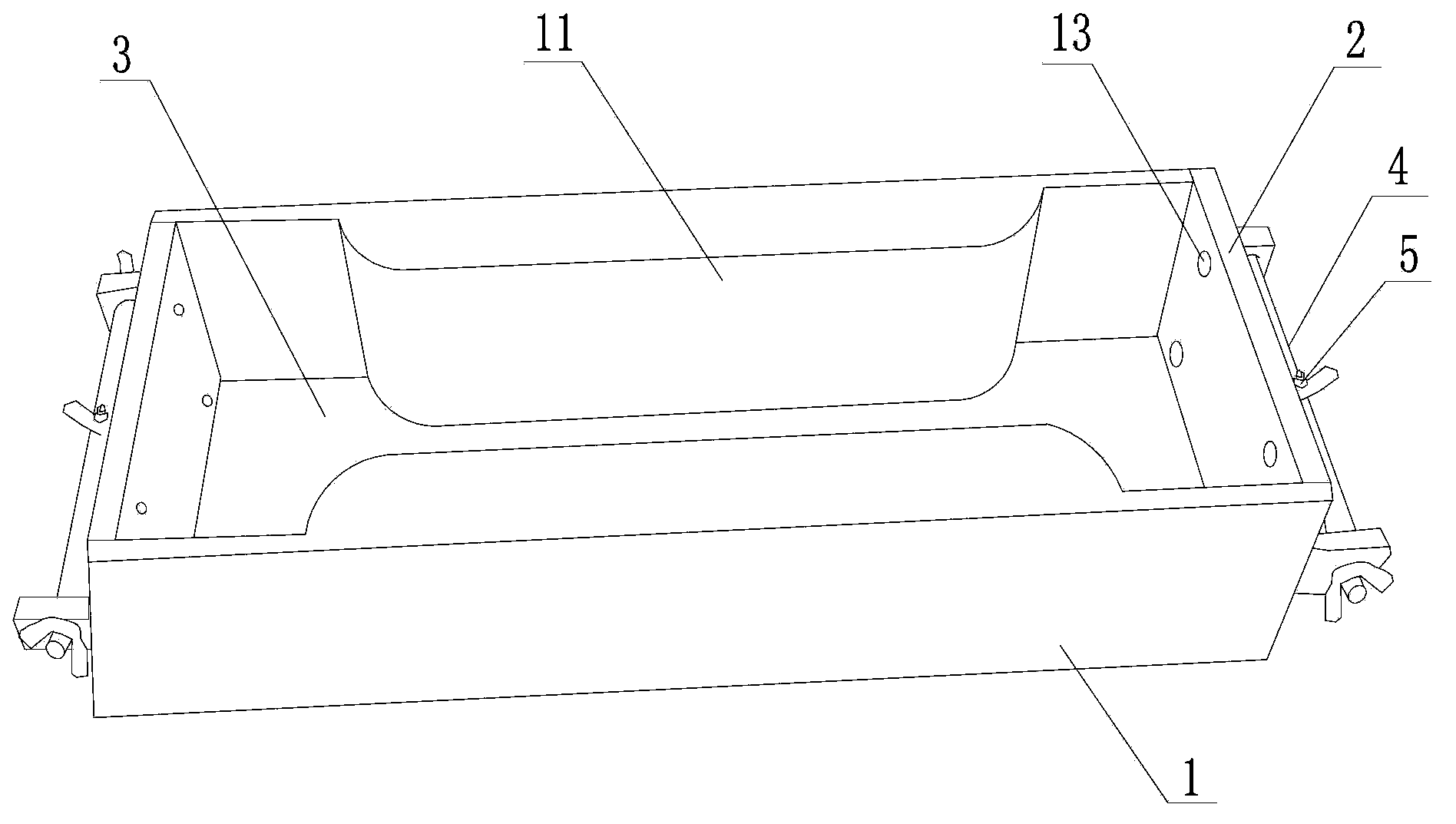

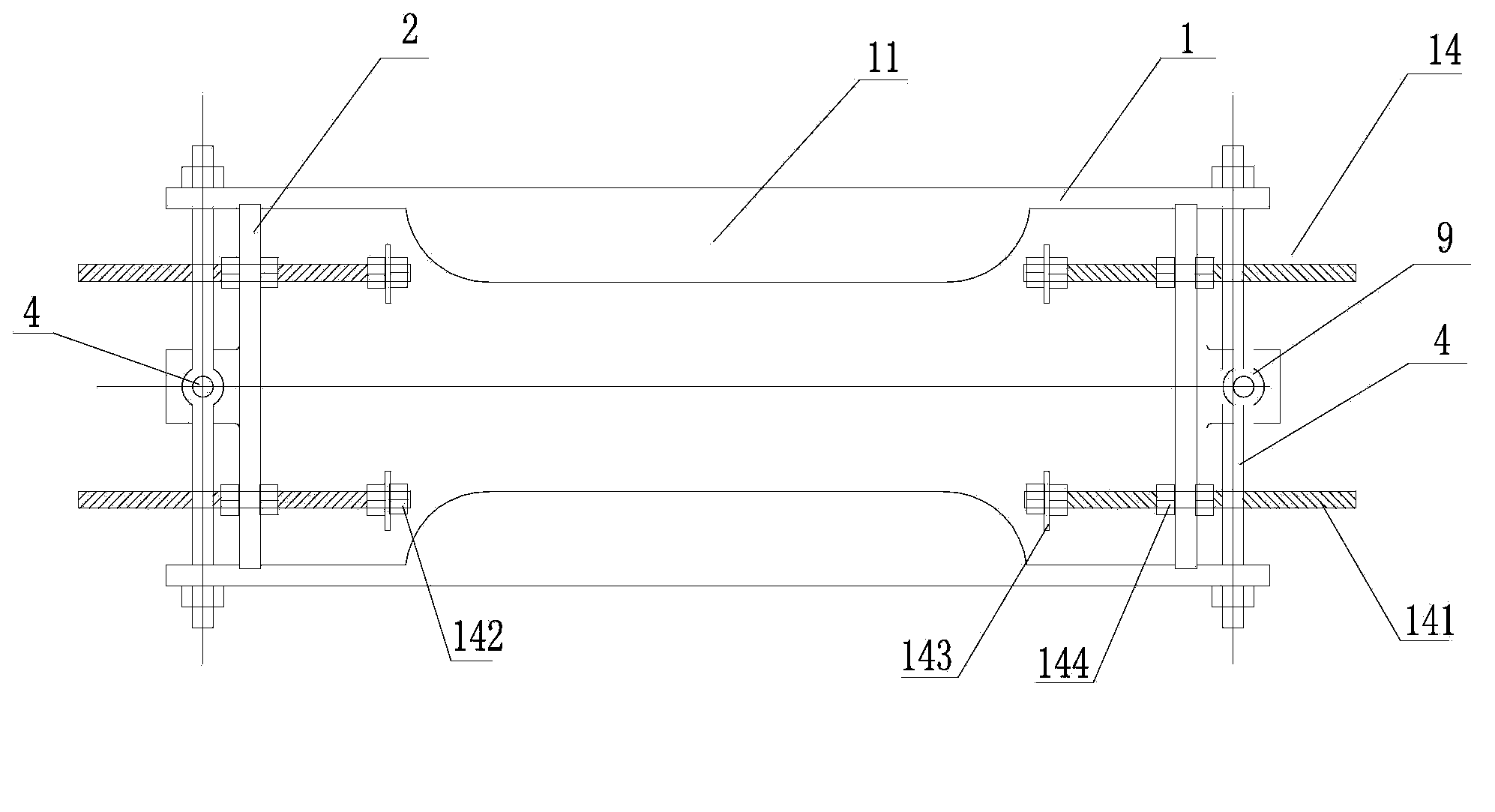

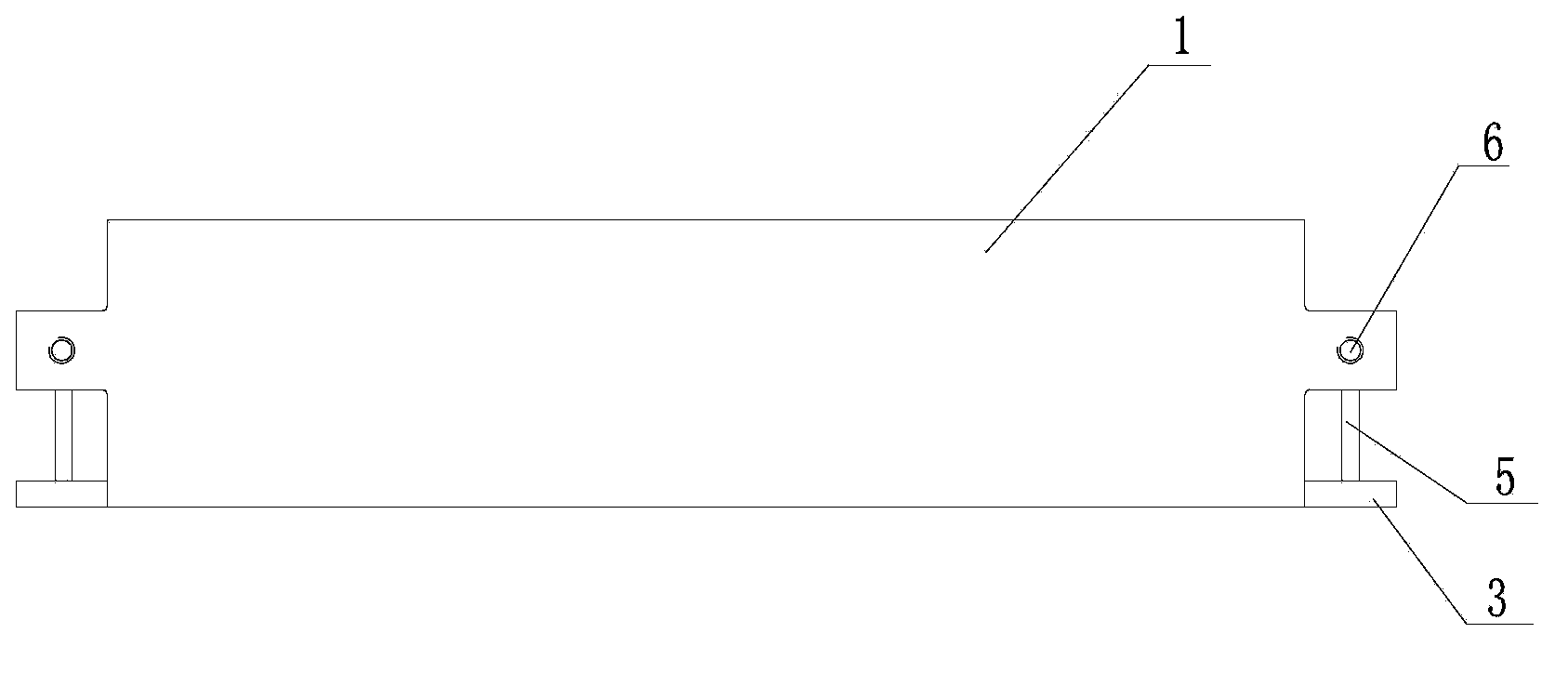

[0041] The concrete axial tensile test piece mold of the present invention comprises a bottom plate 3, the opposite sides of the bottom plate 3 are respectively fixedly connected to the side plates 1, and the other two sides opposite to the bottom plate 3 are provided with end plates 2, bottom plate 3, and side plates 1 Combined with the end plate 2 to form a hollow box with an opening at the top, the opposite sides of the two side plates protrude in the middle to form a boss 11, and the two sides of each side plate 1 are respectively provided with a protruding end plate 2 Planar socket 6, the horizontal rod 4 is connected between the sockets on both sides of the board, the middle of the horizontal rod is provided with a through hole I9, and the vertical rod 5 passes through the through hole and is plugged into the fixed hole 12 provided on the bottom plate , the end plate 2 is limited by the horizontal bar 4 and the vertical bar 5, and each end plate 2 is respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com