Centrifugal type high-temperature sampling probe system

A high-temperature sampling probe and centrifugal technology, which is applied in the direction of sampling device, test sample preparation, etc., can solve problems such as analysis failure and short filter life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

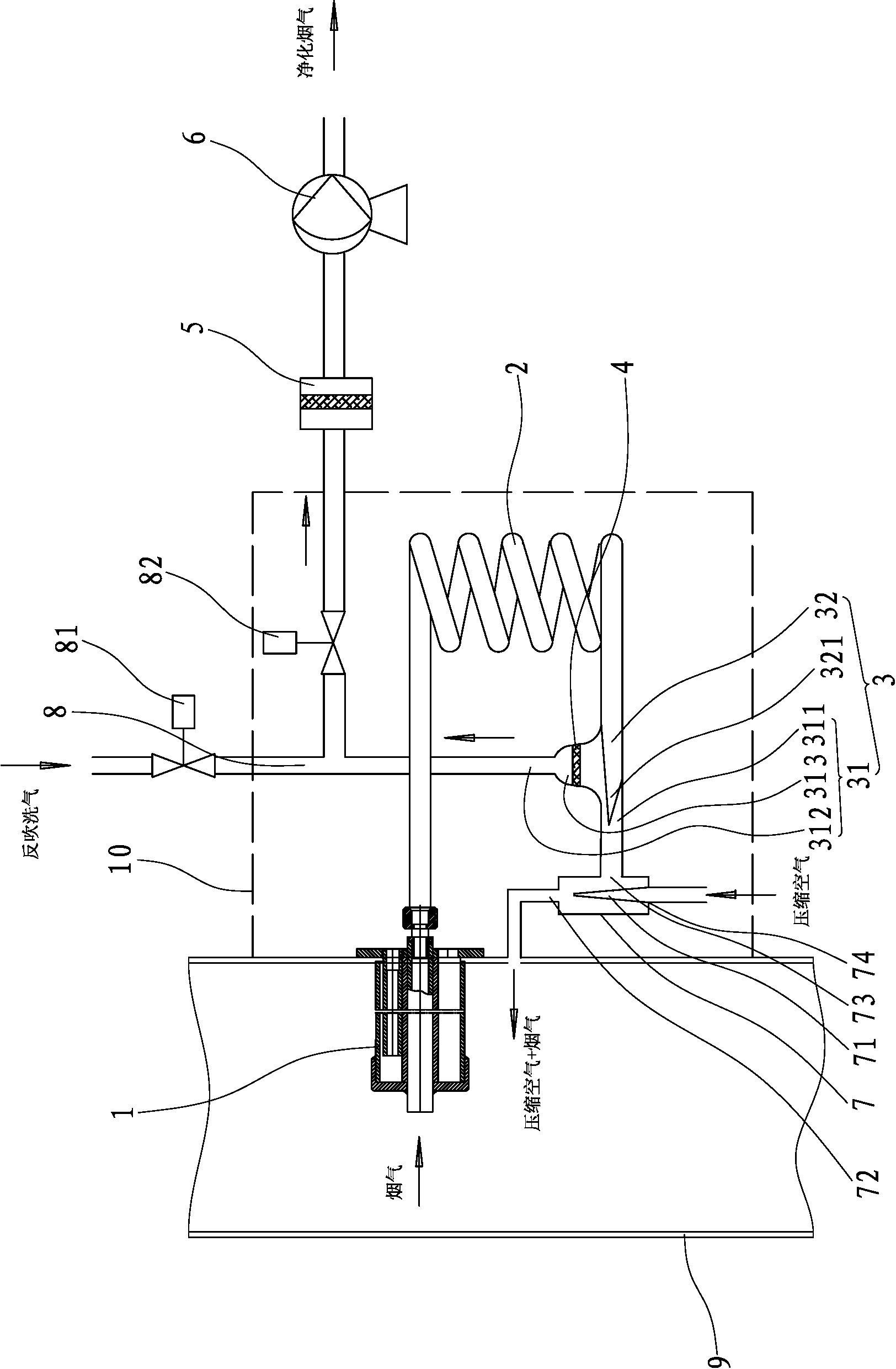

[0018] Such as figure 1 Shown is the centrifugal high-temperature sampling probe system disclosed by the present invention, including a high-temperature sampling probe 1, a centrifugal spiral track 2, an inertial gas-dust separator 3, an inert filter 4, a fine filter 5, an air pump 6 and an ejector 7 .

[0019] The inlet of the high-temperature sampling probe 1 is connected to the flue 9 , the outlet of the high-temperature sampling probe 1 is connected to the inlet of the centrifugal spiral track 2 , and the outlet of the centrifugal spiral track 2 is connected to the inertial gas-dust separator 3 . The centrifugal spiral track 2 can be a cylindrical spiral tube.

[0020] The inertial gas and dust separator 3 is composed of a T-shaped pipe 31 and an isolation pipe 32 . The isolation tube 32 is inserted from one end of the horizontal tube 311 of the T-shaped tube 31, and is sleeved in the horizontal tube 311 of the T-shaped tube 31. The outer end of the isolation tube 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com