Miniature yarn tension measuring sensor

A technology for measuring sensor and yarn tension, applied in the direction of tension measurement, etc., can solve the problems of yarn breakage, affecting yarn weaving efficiency and weaving quality, unstable yarn tension, etc., to achieve high precision and improve yarn delivery efficiency. and quality, the effect of enhanced control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

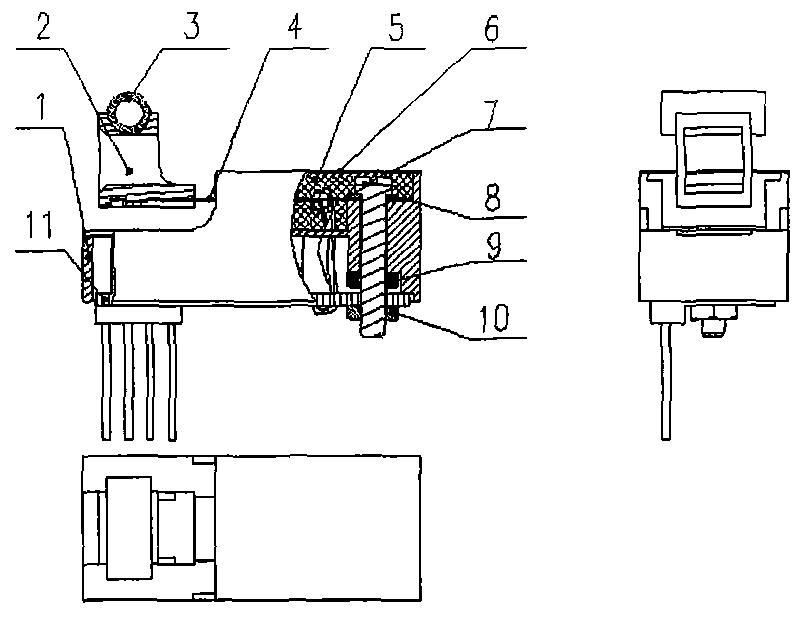

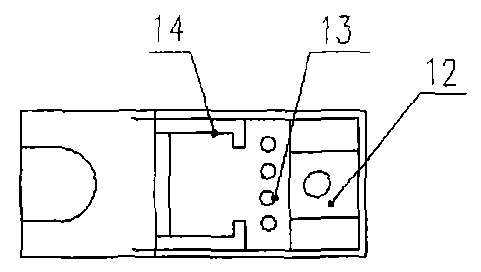

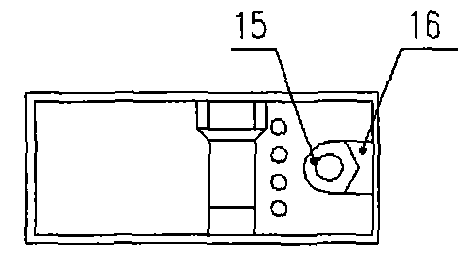

[0016] Such as figure 1 Shown, a kind of miniature yarn tension measuring sensor of the present invention, it comprises housing (1), support (2), porcelain tube (3), elastic element (4), insulation damping glue (5), sealing tape ( 6), screw (7), washer (8), nut (9), nut (10) and transmission circuit board (11), characterized in that: the elastic element (4) passes through the screw (7), washer ( 8) and the nut (9) are fixed on the housing (1); the porcelain tube (3) is bonded and fixed in the groove of the support (2), and the support (2) is bonded to the cantilever end of the elastic element (4); The transmission circuit board (11) is fixed on the casing (1) through nuts (10) and screws (7), and the lead wire of the elastic element (4) passes through the through hole of the casing (1) and the transmission circuit board (11 ) through holes are welded on the transmission circuit board (11); the sealing tape (6) is glued on the upper end of the casing (1), and the casing (1) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com