Honeycomb board online detection system and detection method

A detection system and honeycomb board technology, applied in the detection field based on image recognition technology, can solve the problems of low measurement accuracy, small measurement range, and increased measurement workload of total stations, so as to improve detection efficiency, intuitive detection results, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

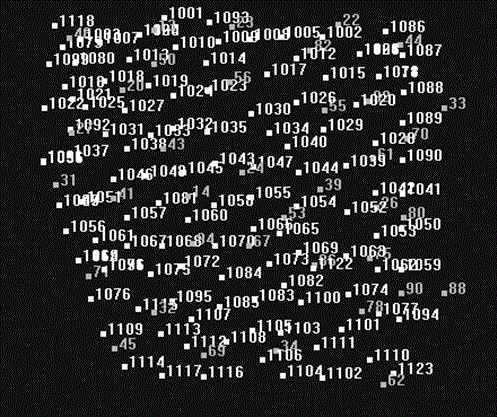

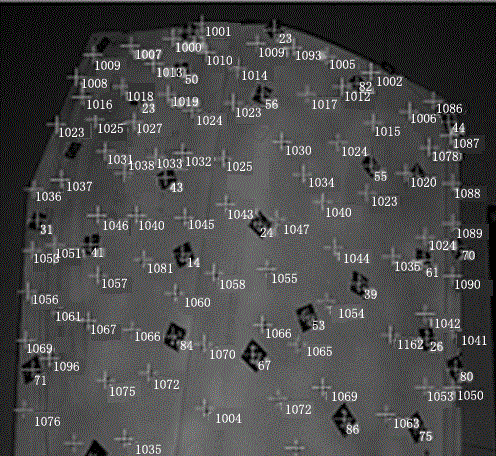

[0043] In this embodiment, the online rapid detection of the honeycomb board to be tested is carried out by constructing a honeycomb board online detection system:

[0044] 1. Honeycomb board online detection system

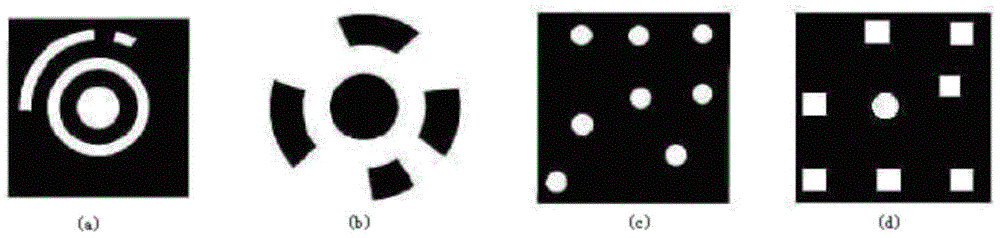

[0045] Such as figure 1As shown, construct the described honeycomb board online inspection system, including a three-coordinate measuring instrument with an articulated arm, an image acquisition module and a control module for collecting images of the surface of the honeycomb board, and the image acquisition module is installed on the three-coordinate measuring instrument On the articulated arm, the three-coordinate measuring instrument drives the articulated arm to move according to the control module, and the image acquisition module collects the surface images of the honeycomb panels at different positions according to the movement of the three-coordinate measuring instrument articulated arm; the control module includes image acquisition The surface image of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com