Ultraviolet light solidified multilayer sound insulation laminated wood floor with sandwiched pillow mat structure

A technology of laminated wood flooring and ultraviolet light, which is applied in building structures, floors, buildings, etc., can solve the defects of wear resistance, blister resistance, dry scalding resistance, antistatic defects, unfavorable general home decoration, hardness, and waterproof Poor and other problems, to achieve the effect of not easy to crack, high hardness, strong solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

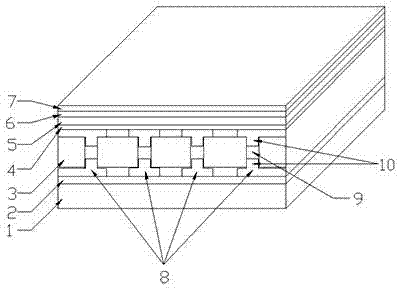

[0020] An ultraviolet light-cured multi-layer sound-insulating laminate flooring with a sandwich pillow structure, comprising a surface layer, a bottom layer and an intermediate layer, the bottom layer is provided with a base board (1), and a waterproof layer (2) is provided on the base board (1) ; The middle layer is provided with a foam layer (3) and a wooden sleeper pad (8); the surface layer is provided with a wood veneer (4), a wood grain layer (5), and a UV-cured topcoat layer (6) layer by layer from bottom to top. ), UV-curable topcoat layer (7). The wooden sleepers (8) are cemented on the waterproof layer (2) in parallel, with gaps adjacent to each other; the lower surface of the wooden veneer (4) on the surface layer is provided with corresponding wooden sleepers (8), two layers of wooden sleepers (8) Form a sandwich structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com