A nozzle control method, device and computer-readable storage medium

A technology of nozzles and nozzle groups, applied in metal processing equipment, manufacturing tools, coating devices, etc., can solve the problems of time or printing substrate waste, and achieve the effect of improving printing efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

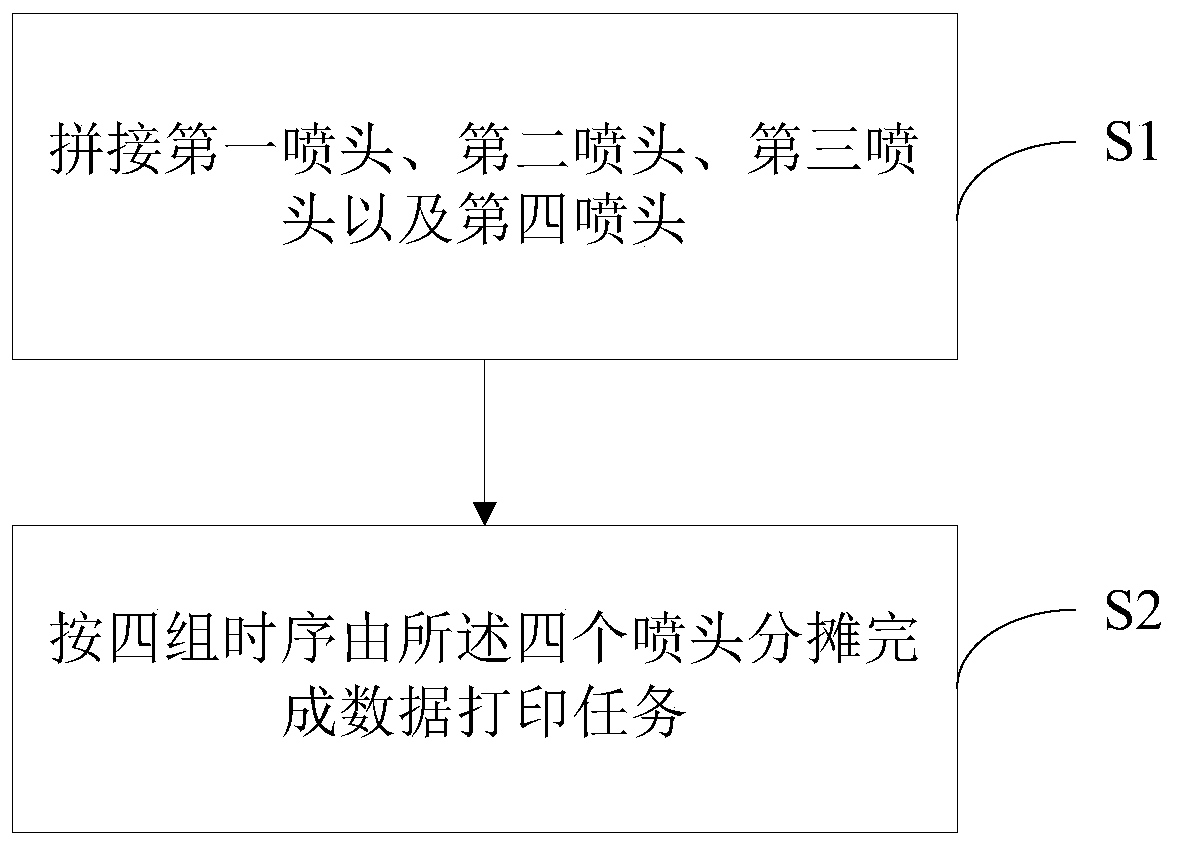

[0030] figure 1 It is a flow chart of the first embodiment of the nozzle control method of the present invention. A nozzle control method, the method comprising:

[0031] S1. Splicing the first nozzle, the second nozzle, the third nozzle and the fourth nozzle. Wherein, the first nozzle and the second nozzle are horizontally spliced, the third nozzle and the fourth nozzle are horizontally spliced, the first nozzle and the third nozzle are vertically spliced, and the first nozzle is spliced vertically. The second nozzle and the fourth nozzle are longitudinally spliced;

[0032] S2. The four print heads share and complete the data printing task according to four groups of time sequences. Wherein, the first data is printed by the first nozzle and the third nozzle of the first nozzle at the first moment, the third data is printed by the fifth nozzle and the seventh nozzle of the second nozzle at the second moment, and the third data is printed by the fifth nozzle and the seven...

Embodiment 2

[0058] Based on the above-mentioned embodiments, this embodiment proposes a rotation rest mechanism in the case of overheating of the nozzles: on the one hand, when the temperature of one or two nozzles in the non-same direction exceeds the set alarm threshold, the set There should be a certain margin for the alarm threshold, so that it can continue to work for a short period of time. On the other hand, if the alarming nozzle needs to take a rest in rotation, a mechanism for the nozzle to take a rest in rotation should be set.

[0059] In this embodiment, it is first necessary to solve the finishing work of the data printing task when the nozzle is overheated, specifically:

[0060] When overheating occurs during the printing process of the nozzle, directly call the data of the second half of this task. In order to achieve the seamless connection of data, it is necessary to count the number of printing frames. Once the nozzle is overheated, the minimum black block unit (such a...

Embodiment 3

[0065] In the above embodiment, when the nozzle is overheated, the finishing work of the data printing task when the nozzle is overheating is solved. In this embodiment, after the finishing work of the data printing task is completed, the working state of the nozzle is switched, specifically :

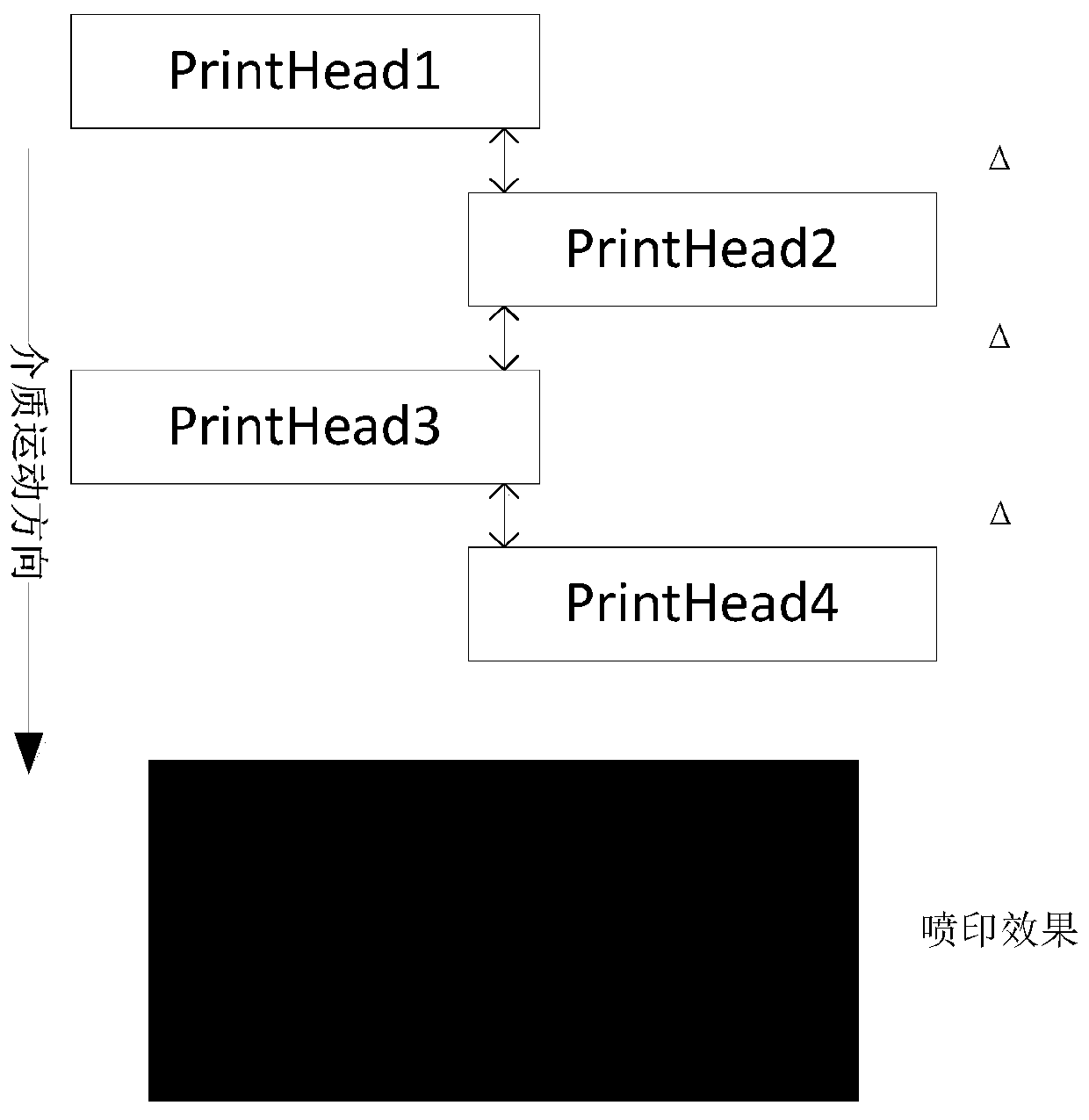

[0066] Such as figure 2 Shown is a schematic diagram of nozzle splicing in the nozzle control method of the present invention. If one of the four nozzles is overheated, the four nozzles are grouped, wherein:

[0067] The first spray head and the second spray head are in a first group;

[0068] The first spray head and the fourth spray head are in the second group;

[0069] The third nozzle and the second nozzle are in a third group;

[0070] The third spray head and the fourth spray head are in a fourth group.

[0071] It can be understood that, among the above four groups, any group of nozzles can independently complete the data printing task.

[0072] Further, if one of the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com