Novel FRP rib adhesive type anchorage device with screw plug and mounting method of anchorage device

A bonded and screw plugging technology, applied in structural elements, building materials processing, building components, etc., can solve the problems of long anchor tube length, high cost, complicated processing, etc., to improve load-bearing capacity, strengthen constraints, The effect of low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

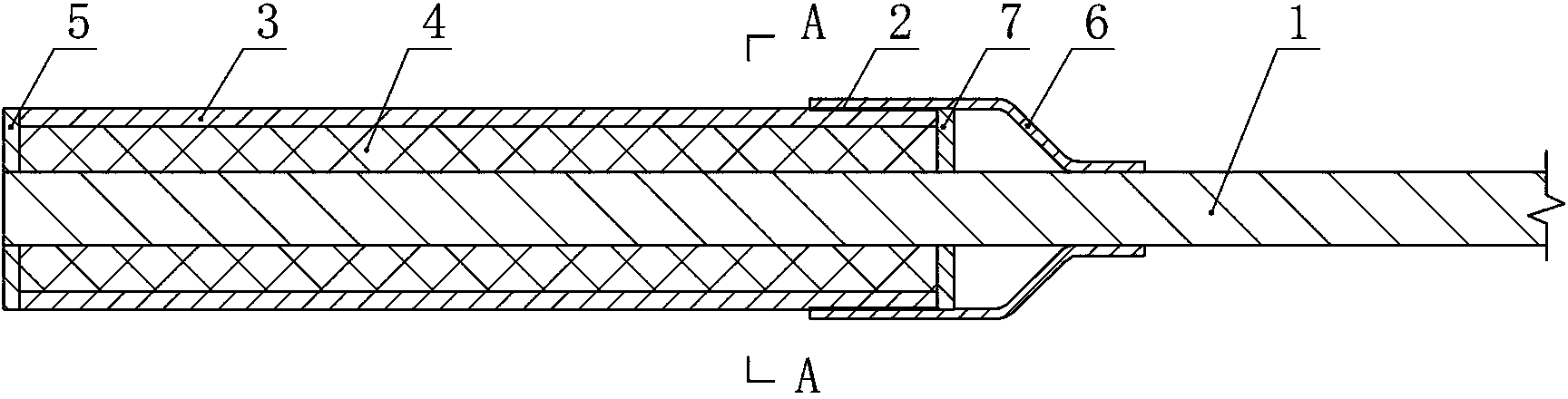

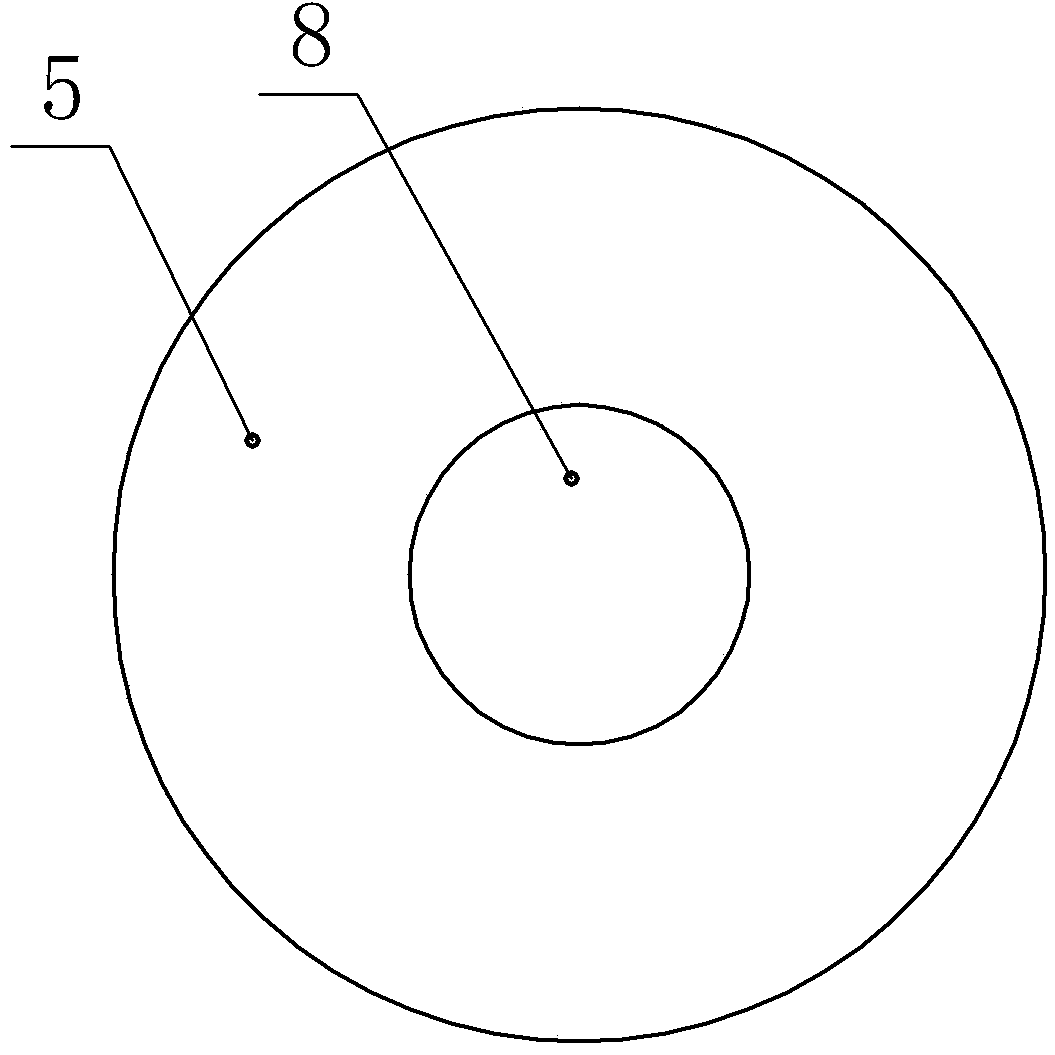

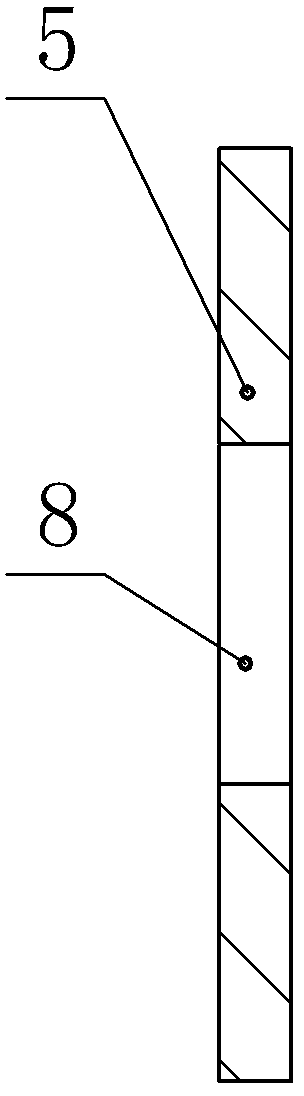

[0028] Example 1: see Figure 1~4 A new type of FRP tendon tape screw plug bonded anchorage, including an anchor barrel 3 and an annular gasket, the two ends of the anchor barrel are respectively fixed with annular gaskets 5, 7, wherein, one end of the anchor barrel 3 is a free end, and the other end is a free end. For the tension end, the free end pastes the ring gasket 5, the tension end pastes the ring gasket 7, and also includes a screw plug 6, the screw plug 6 is threaded with the tension end of the anchor tube 3, and the ring gasket 5 and the ring gasket A central through hole for fitting FRP bars is respectively provided at the center of the sheet 7 , and the center of the ring gasket is located on the center line of the anchor cylinder 3 . The screw plug 6 is composed of a cylindrical section connected to the outer wall of the anchor tube 3, a diameter reducing section and a cylindrical boss section set on the outer surface of the FRP bar, and the screw plug 6 adopts a...

Embodiment 2

[0029] Embodiment 2: A method for installing the novel FRP tendon and plug-bonded bonded anchor containing the above-mentioned claim 1, comprising the following steps:

[0030] Step 1: Clean and derust the inside of the anchor barrel 3, and process the external thread 2 on the tensile end of the anchor barrel 3;

[0031] Step 2: Fix the ring gasket 5 on the free end surface of the anchor cylinder 3 and seal it;

[0032] Step 3: Put one end of the FRP tendon 1 into the screw plug 6;

[0033] Step 4: Fill the anchor tube 3 with adhesive from the tensile end of the anchor tube 3 until the inside of the anchor tube 3 is filled with the adhesive, and the glue filling is completed, and then set the FRP tendon 1 on one end of the screw plug 6 Insert the central through hole of the annular gasket 7 at the tension end into the anchor cylinder 3, so that its end enters the central through hole 8 of the annular gasket at the free end of the anchor cylinder 3;

[0034] Step 5: Fix the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com