Oil and fat refining process

A process and oil technology, applied in the field of oil refining technology, can solve the problems of poor oil quality and incomplete process, and achieve the effects of reducing oil content, improving social benefits, and improving hydration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

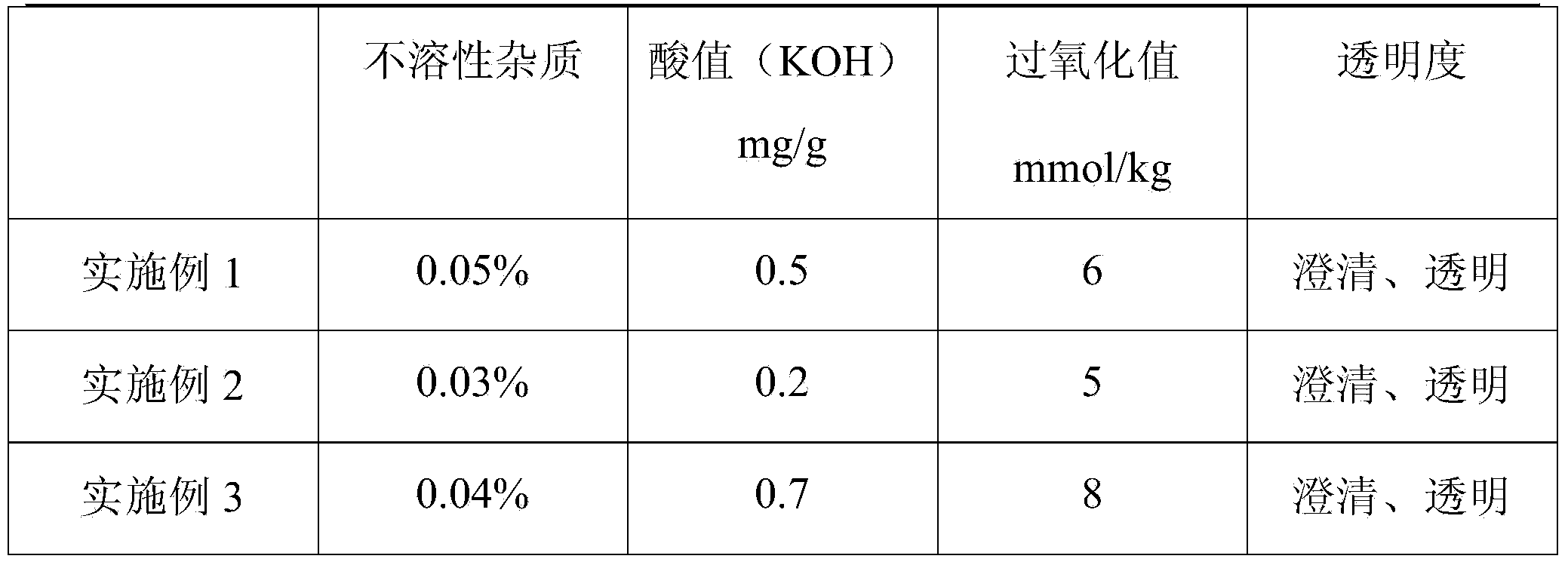

Embodiment 1

[0015] Take 1000kg of crude vegetable oil, first pass the crude oil through a crude oil filter to remove impurities, then enter the plate steam heater, heat it to 75°C, add 2.8kg of 80% phosphoric acid and mix it, then send it to the acid reaction tank, stay for 15min, and then transport it to the plate steam heater. Cool the water cooler to 60°C, add dilute lye, the concentration of lye is 10°Be', mix and enter the neutralization reaction tank, the reaction temperature is 60°C, stay for 30min, enter the centrifuge for separation, and the separated oil enters the vacuum The dryer is dehydrated and transferred to the decolorization section. The degummed alkali refining oil is sent to the plate heater through the conveying pump, heated to 115°C, enters the clay mixing tank and mixed with the quantitative clay for 15 minutes, then overflows into the decolorizing tower, stays for 30 minutes, and is transported into the decolorization tower through the conveying pump. The vertical f...

Embodiment 2

[0017] Take 1000kg of crude vegetable oil, first pass the crude oil through a crude oil filter to remove impurities, then enter the plate steam heater, heat it to 78°C, add 2.9kg of 80% phosphoric acid and mix it, then send it to the acid reaction tank, stay for 20min, and then transport it to the plate steam heater. Cool the water cooler to 70°C, add dilute lye, the concentration of lye is 20°Be', mix and enter the neutralization reaction tank, the reaction temperature is 63°C, stay for 40min, enter the centrifuge for separation, and the separated oil enters the vacuum The dryer is dehydrated and transferred to the decolorization section. The degumming alkali refining oil is sent to the plate heater through the conveying pump, heated to 120°C, enters the clay mixing tank and mixed with the quantitative clay for 20 minutes, overflows into the decolorizing tower, stays for 40 minutes, and is transported into the decolorization tower through the conveying pump. The vertical filte...

Embodiment 3

[0019] Take 1000kg of crude vegetable oil, first pass the crude oil through a crude oil filter to remove impurities, then enter the plate steam heater, heat to 80°C, add 3kg of 80% phosphoric acid and mix, send it to the acid reaction tank, stay for 30min, and then transport it to the plate water Cool the cooler to 75°C, add dilute lye, the concentration of lye is 24°Be', mix and enter the neutralization reaction tank, the reaction temperature is 65°C, stay for 45min, enter the centrifuge for separation, and the separated oil enters the vacuum drying After dehydration in the machine, it is transferred to the decolorization section. The degumming alkali refining oil is sent to the plate heater through the conveying pump, heated to 130°C, enters the clay mixing tank and mixed with the quantitative clay for 30 minutes, then overflows into the decolorization tower, stays for 45 minutes, and is transported into the vertical tank by the conveying pump. The oil and white clay are sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com