Dipropyl phenylphosphinate flame retardant composition and application method thereof

A technology of dipropyl phenylphosphinate and its application method, which is applied in the field of dipropyl phenylphosphinate flame retardant compositions, can solve problems such as poor performance, high price of flame retardants, and easy precipitation, and achieve Improved compatibility, low equipment investment, and high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

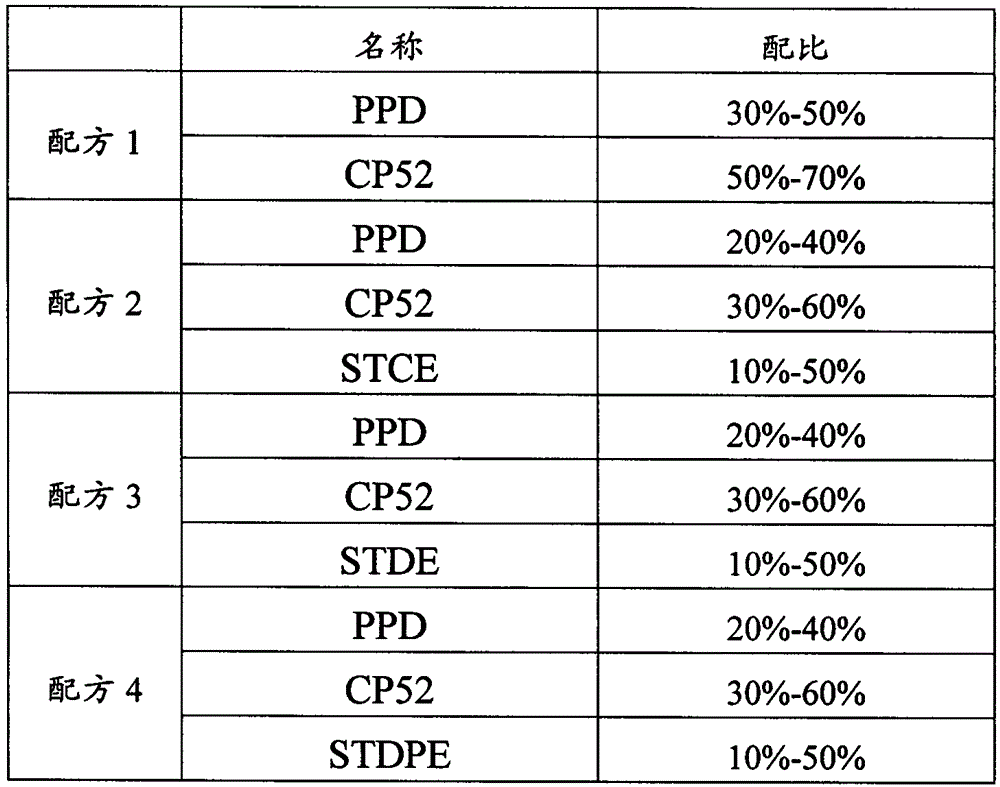

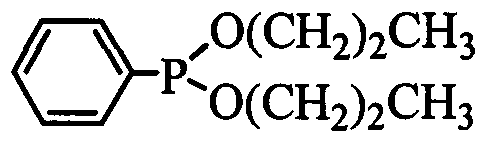

[0029] Example 1 Add different proportions of PPD and CP52 to polyvinyl chloride, stir evenly, extrude a sample strip with a diameter of about 3 mm at melting temperature with an XJ-01 extruder, and measure it with an HC900-2 oxygen index tester The limiting oxygen index, the results are shown in Table 2.

[0030] Table 2 Flame retardant data of PVC compounded by flame retardant PPD and CP52

[0031]

Embodiment 2

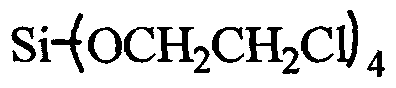

[0032] Example 2 Add different proportions of PPD, CP52 and STCE to polyvinyl chloride, stir evenly, extrude a sample strip with a diameter of about 3mm at the melting temperature with an XJ-01 extruder, and use a HC900-2 oxygen index tester The limiting oxygen index was measured, and the results are shown in Table 3.

[0033] Table 3 Flame retardant data of PVC compounded by flame retardant PPD, CP52 and STCE

[0034]

Embodiment 3

[0035] Example 3 Add different proportions of PPD, CP52 and STDE to polyvinyl chloride, stir evenly, extrude a sample strip with a diameter of about 3mm at the melting temperature with an XJ-01 extruder, and use a HC900-2 oxygen index tester Measure its limiting oxygen index, and the results are shown in Table 4.

[0036] Table 4 Flame retardant data of PVC compounded by flame retardant PPD, CP52 and STDE

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com