Preparation method for sea anemone polysaccharide and application thereof to tumor resistance

A sea anemone polysaccharide and sea anemone technology, applied in the field of preparation of sea anemone polysaccharides with anti-tumor activity, can solve the problems of unreported research on the biological activity of A. good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

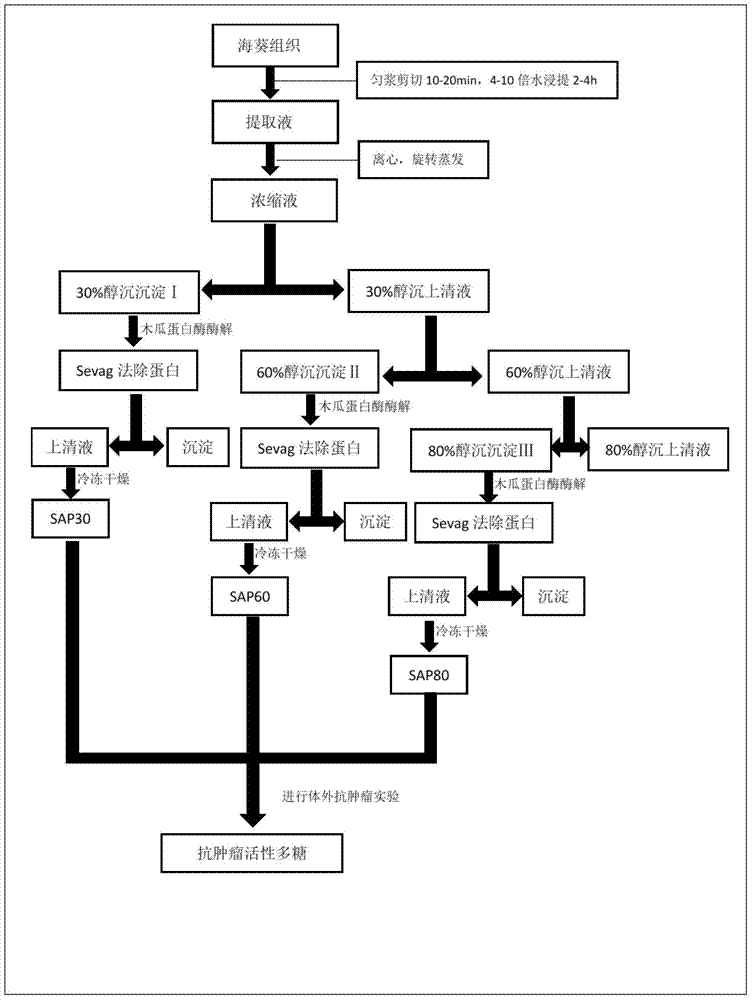

[0040] a) Raw material processing: clean the outer surface of the fresh star worm, cut it, wash off the contents of its coelenterate, and cut it into pieces;

[0041] b) cutting the homogenate of crushed sea anemone for 10 minutes, then adding water with a volume 4 times the volume of the homogenate to the homogenate, and leaching at 30° C. for 2 hours to obtain an extract;

[0042] c) centrifugation of the extract: 8000rpm, 4°C, centrifugation for 5min, to obtain a supernatant;

[0043] d) Concentration: Concentrate the supernatant by rotary evaporation under reduced pressure (45° C.) to 1 / 4 of the original volume to obtain a concentrated solution;

[0044]e) Alcohol precipitation: add 95% ethanol to the concentrated solution until the volume fraction of ethanol is 30%, place it at 4°C for 4 hours, centrifuge and separate to obtain the precipitate I and supernatant I, and continue to add to the supernatant I Add 95% ethanol until the ethanol volume fraction is 60%, let it st...

Embodiment 2

[0049] a) Raw material processing: clean the outer surface of the fresh star worm, cut it, wash off the contents of its coelenterate, and cut it into pieces;

[0050] b) Cut the homogenate of crushed sea anemone for 15 minutes, add 6 times the volume of water to the homogenate, and extract at 50° C. for 3 hours to obtain an extract;

[0051] c) centrifugation of the extract: 9000rpm, 4°C, centrifugation for 10min to obtain a supernatant;

[0052] d) Concentration: Concentrate the supernatant by rotary evaporation under reduced pressure (45° C.) to 1 / 4 of the original volume to obtain a concentrated solution;

[0053] e) Alcohol precipitation: add 95% ethanol to the concentrated solution until the volume fraction of ethanol is 30%, place it at 4°C for 6 hours, centrifuge and separate to obtain the precipitate I and supernatant I, and continue to add to the supernatant I Add 95% ethanol until the ethanol volume fraction is 60%, let it stand for the same time, centrifuge and sep...

Embodiment 3

[0058] a) Raw material processing: clean the outer surface of the fresh star worm, cut it, wash off the contents of its coelenterate, and cut it into pieces;

[0059] b) Cut the homogenate of crushed sea anemone for 20 minutes, add 10 times the volume of water to the homogenate, and extract at 70° C. for 4 hours to obtain an extract;

[0060] c) centrifugation of the extract: 10000rpm, 4°C, centrifugation for 15min to obtain a supernatant;

[0061] d) Concentration: Concentrate the supernatant by rotary evaporation under reduced pressure (45° C.) to 1 / 4 of the original volume to obtain a concentrated solution;

[0062] e) Alcohol precipitation: add 95% ethanol to the concentrated solution until the volume fraction of ethanol is 30%, place it at 4°C for 8 hours, centrifuge and separate to obtain the precipitate I and supernatant I, and continue to add to the supernatant I Add 95% ethanol until the ethanol volume fraction is 60%, let it stand for the same time, centrifuge and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com