Tempered boroaluminosilicate glass free of color change

A technology of boroaluminosilicate and glass, which is applied in glass tempering, glass manufacturing equipment, glass/slag layered products, etc., and can solve problems such as difficult concentration, consumption, and easy discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

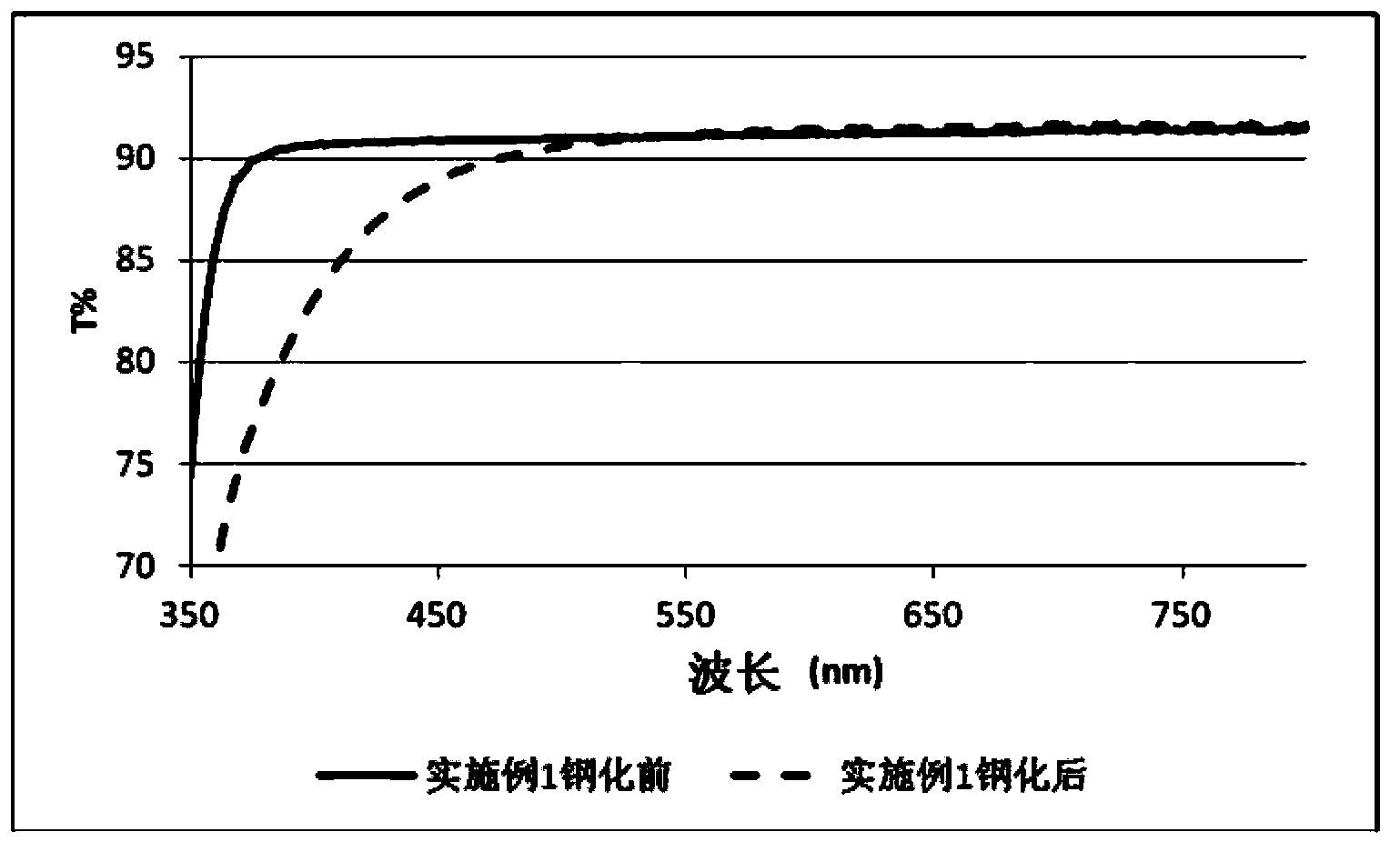

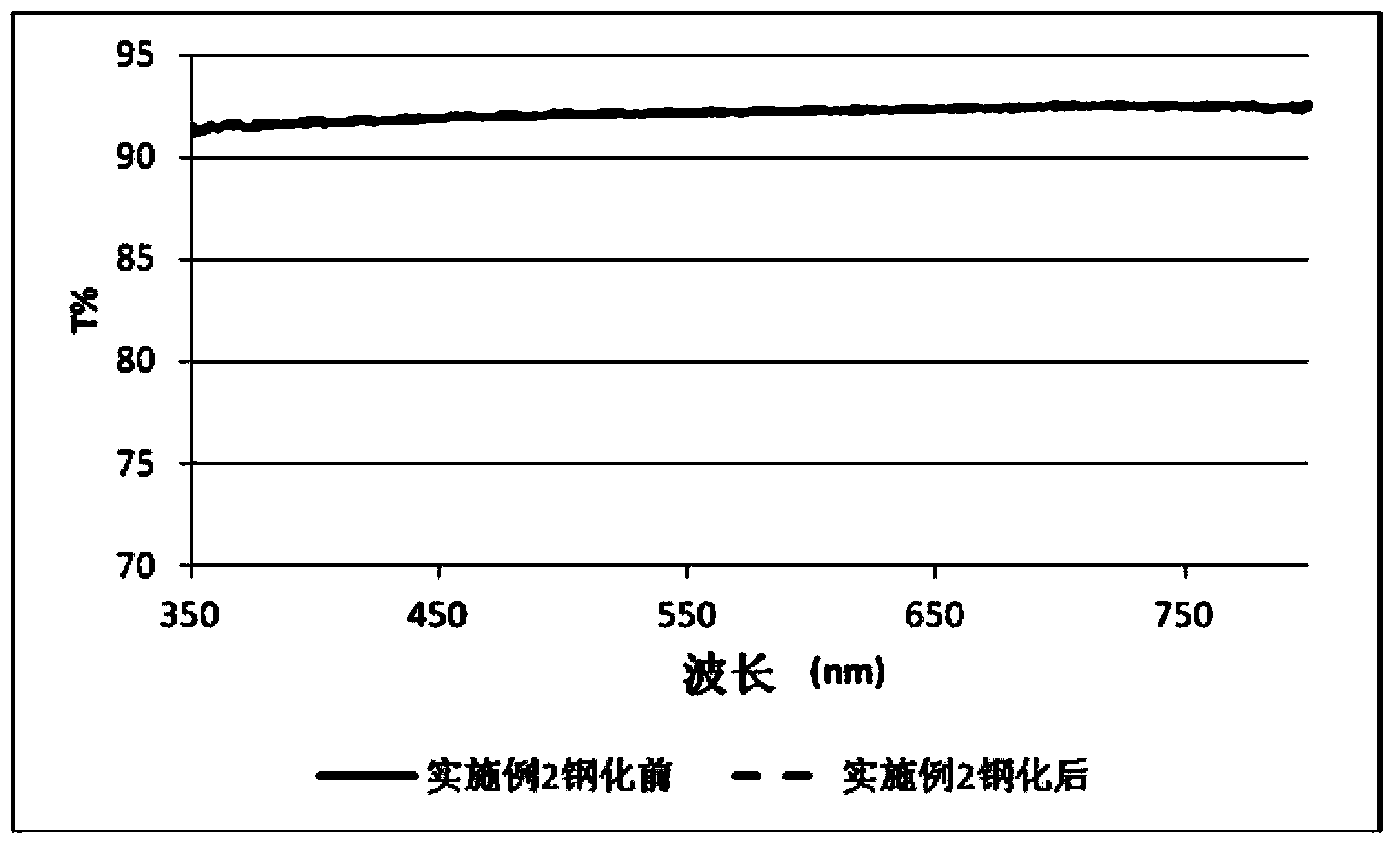

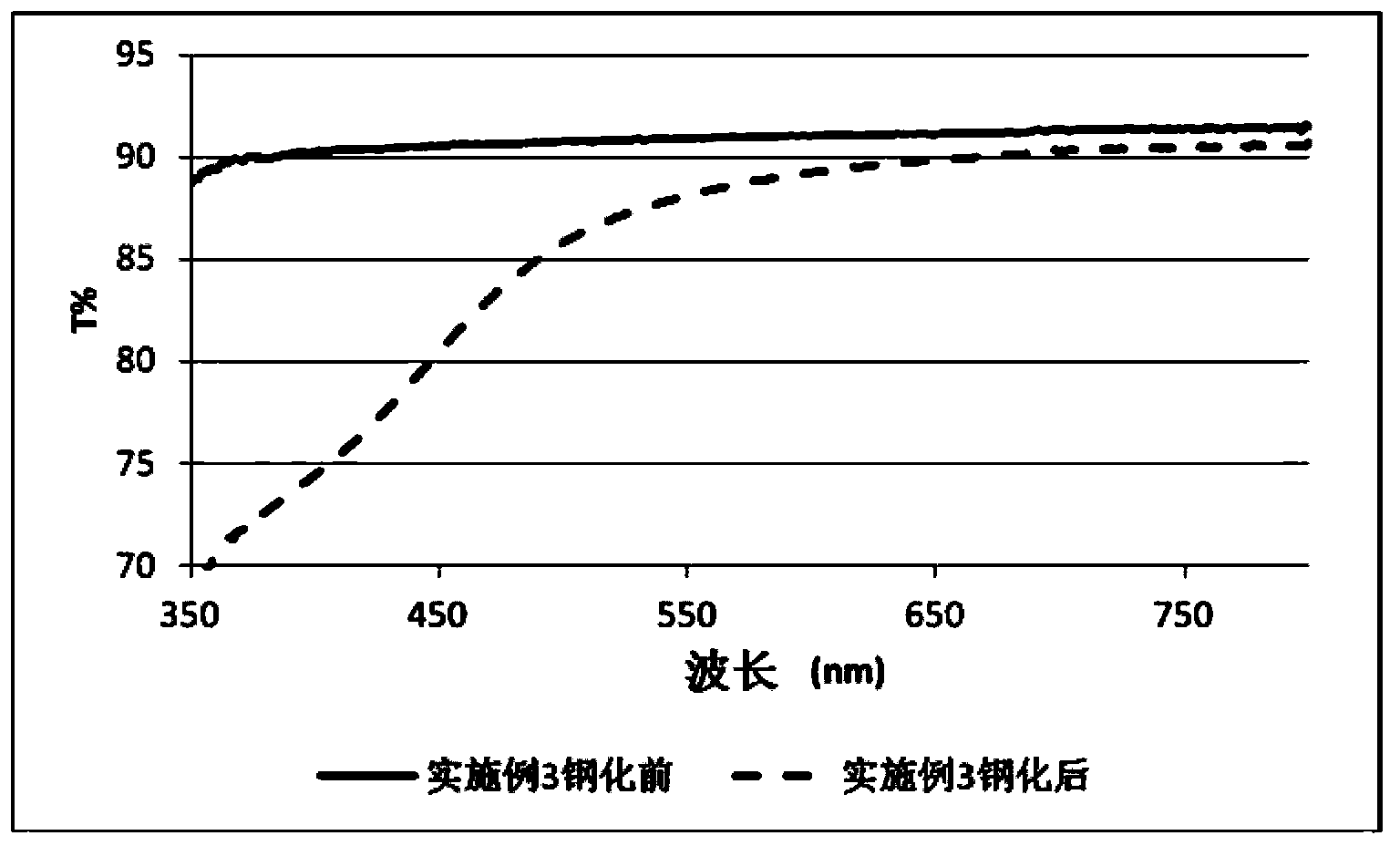

Embodiment 1

[0165] The CS and DoL values of Example 1 and Example 4 were measured by the FSM-6000 surface stress meter developed and produced by Japan Orihara Research Institute. These two values are usually used to characterize the strength of glass after thermal tempering or chemical tempering. Tempered glass has a higher CS value, which generally means it is less prone to breakage at the same thickness. A large DoL value means that even if some deep scratches appear on the glass surface, the tempered glass can still maintain its strength unaffected. However, in the case of thin glass itself, too high CS plus too deep DoL will increase the risk of self-burst of the glass, because in this case, the tensile stress at the center of the glass will become very high. powerful.

[0166] The 4-point bend (4PB) method is another commonly used technique for measuring the strength of flat glass. This method measures the maximum load force (F) of the glass substrate and calculates the streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com