ED (electrodialysis) water treatment system with intelligent temperature-adjusting, voltage-adjusting and ultrasonic effects

A technology of water treatment system and intelligent temperature adjustment, applied in the field of water treatment, can solve the problems of reducing electrodialysis desalination capacity, water crisis, increasing membrane resistance, etc., to reduce ion association phenomenon, increase ion migration speed, overcome concentration The effect of poor polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

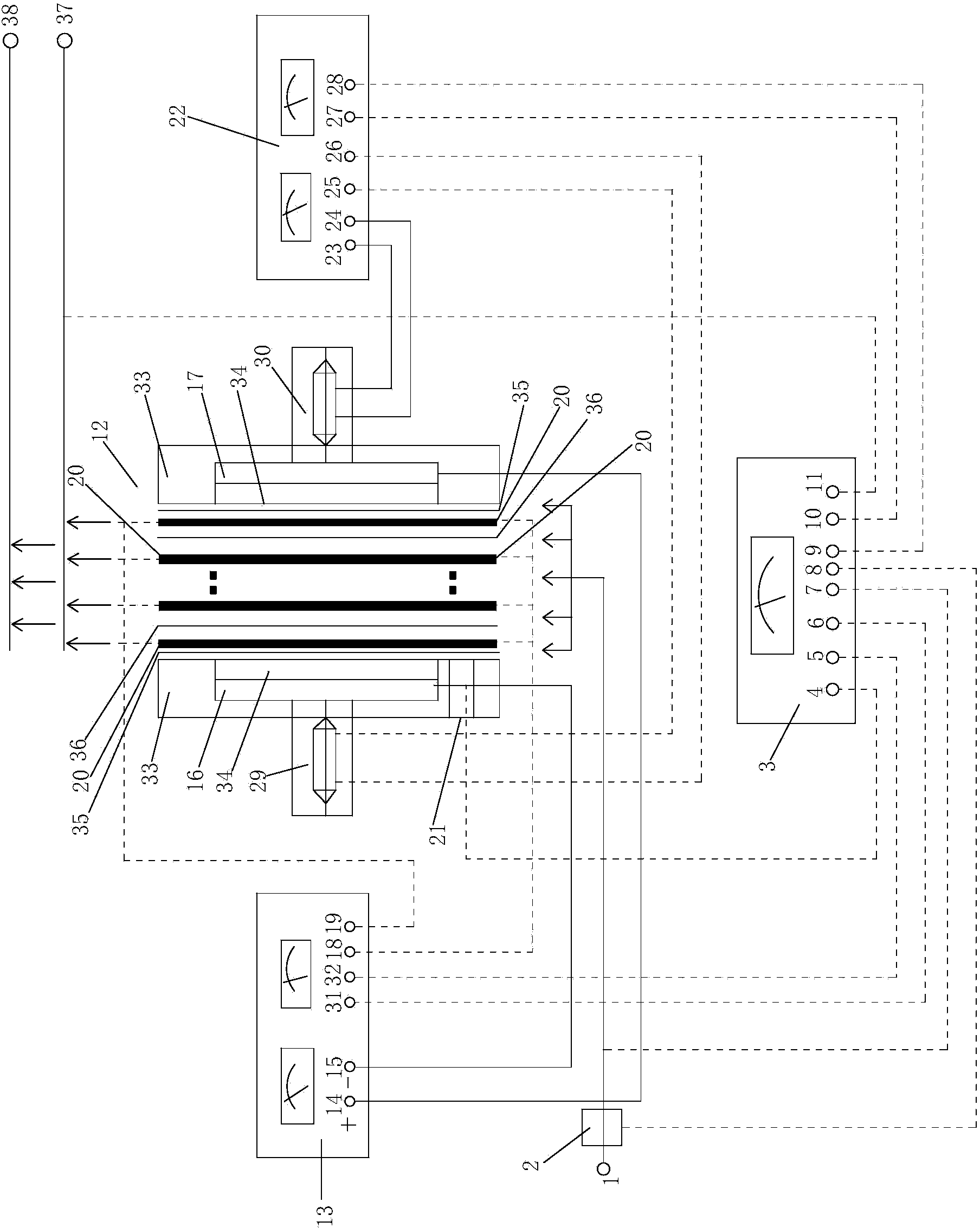

[0034] A kind of electrodialysis water treatment system of intelligent temperature regulation, pressure regulation and ultrasonic effect provided by the present invention, its structural diagram (see figure 1 ); the system includes: electrodialysis membrane stack 12 (see figure 2 ), electric field current temperature regulator 13, ultrasonic regulator 22, water sample central processing unit 3.

[0035] The voltage output port 14 of the electric field current temperature regulator 13 is connected with the anode 17 of the adjustable voltage electrode plate of the electrodialysis membrane stack 12, and the voltage output port 15 is connected with the negative electrode 16 of the adjustable voltage electrode plate of the electrodialysis membrane stack 12; The side support net 34 places the electrode plate anode and cathode solids on the main body support material 33 of the temperature-adjustable electrodialysis membrane stack 12 respectively; 20 groups of single-layer partition...

Embodiment 2

[0042] Use the same electrodialysis water treatment system with intelligent temperature regulation, pressure regulation and ultrasonic action as in Example 1; the device parameters of this example: the model of the ion exchange membrane used in the electrodialysis membrane stack is the same as that of Example 1, and the membrane pair Number N=200; electric heating double-layer partitions are used, the size of which is 800*1600mm, and the thickness of electric heating double-layer partitions is 2.0mm; the time relay in the ultrasonic regulator is set to open; the electrodialysis membrane stacks 12 of the system are simultaneously open Electric heating partition and ultrasonic function; a single electric heating double-layer partition 20 is between the negative film 35 and the positive film 36, forming a thermal film coupling effect; the electric heating double-layer partition 20 (see Figure 5 , Image 6 ) In the double-layer partition, one layer 40 plays the role of stirring, ...

Embodiment 3

[0044] An electrodialysis water treatment system using the same intelligent temperature regulation, pressure regulation and ultrasonic electrodialysis water treatment as in Example 1; the device parameters of this embodiment are: domestic homogeneous ion exchange membranes are used, and the number of membrane pairs N= 200; use electric heating double-layer partition (see Figure 5 , Image 6 ), its size is 800*1600mm, the thickness of electric heating double-layer partition is 2.0mm; The main support material of the stack 12 is polyvinylidene fluoride; the electrode material is a titanium wire-coated ruthenium electrode. The raw water sample analysis inlet 7 of the water sample central processor 3 takes the raw water sample, and after the analysis and detection of the water sample central processor 3, it is determined that the raw water is standard seawater, and its composition and content are: NaCl 26.423 g / L, MgSO 4 3.213 g / L, MgCl 2 2.348 g / L, CaCl 2 1.232 g / L, KCl 0.71...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com