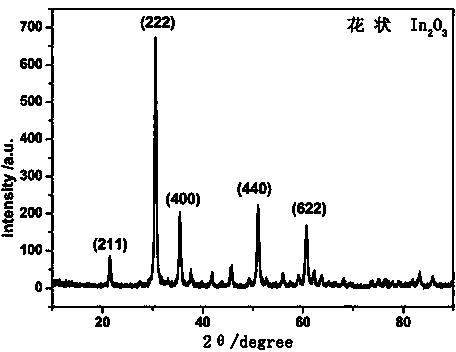

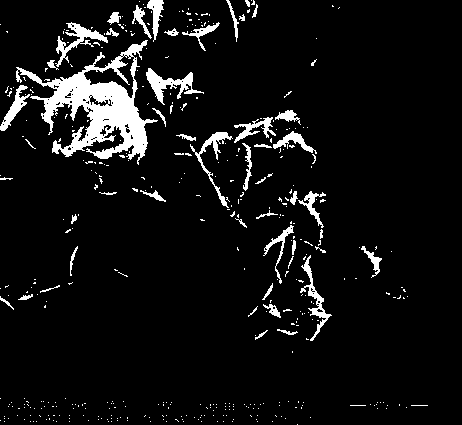

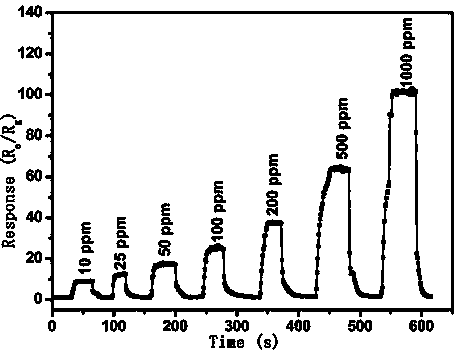

Preparation method of flower type indium oxide gas-sensitive material with hierarchical structure

A hierarchical structure, indium gas-sensing technology, applied in the field of sensing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] (1) Mixing and stirring: Prepare a mixed solution of dimethylformamide and deionized water with a volume ratio of 1:1, the total volume is 30 ml, and the molar ratio is 2: Add 1% sodium citrate and indium chloride into the mixed solution respectively, stir well, the molar ratio of urea is 5:1, add urea as precipitant, stir for 30 minutes, mix well.

[0025] (2) Solvothermal reaction and solid-liquid separation: transfer the mixed solution obtained in step (1) into a 50-milliliter inner polytetrafluoroethylene reaction kettle, and place the reaction kettle in a precision constant temperature electric drying oven for 170 After reacting at ℃ for 10 hours, it was cooled to room temperature. The resulting solution was poured off the supernatant, and the precipitate was transferred to a beaker, washed with distilled water and absolute ethanol several times, and centrifuged.

[0026] (3) Drying and calcination: the solid product obtained in step (2) was placed in a drying ove...

example 2

[0029] (1) Mixing and stirring: Prepare a mixed solution of dimethylformamide and deionized water with a volume ratio of 0.7:1, the total volume is 30 ml, and the molar ratio is 3: Add 1% sodium citrate and indium chloride into the mixed solution respectively, stir well, the molar ratio of urea is 5:1, add urea as precipitant, stir for 30 minutes, mix well.

[0030] (2) Solvothermal reaction and solid-liquid separation: transfer the mixed solution obtained in step (1) into a 50-milliliter inner Teflon reaction kettle, and place the reaction kettle in a precision constant temperature electric drying oven for 180 After reacting at ℃ for 13 hours, it was cooled to room temperature. The resulting solution was poured off the supernatant, and the precipitate was transferred to a beaker, washed with distilled water and absolute ethanol several times, and centrifuged.

[0031] (3) Drying and calcination: the solid product obtained in step (2) was placed in a drying oven, dried at 60 ...

example 3

[0033] (1) Mixing and stirring: prepare a mixed solution of dimethylformamide and deionized water with a volume ratio of 0.5:1, the total volume is 30 ml, and the molar ratio is 2: Add 1% sodium citrate and indium chloride into the mixed solution respectively, stir well, the molar ratio of urea is 5:1, add urea as precipitant, stir for 30 minutes, mix well.

[0034] (2) Solvothermal reaction and solid-liquid separation: transfer the mixed solution obtained in step (1) into a 50-milliliter inner polytetrafluoroethylene reaction kettle, and place the reaction kettle in a precision constant temperature electric drying oven for 160 After reacting at ℃ for 15 hours, it was cooled to room temperature. The resulting solution was poured off the supernatant, and the precipitate was transferred to a beaker, washed with distilled water and absolute ethanol several times, and centrifuged.

[0035] (3) Drying and calcination: the solid product obtained in step (2) was placed in a drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com